Traction substation busbar potential transformer on-line monitoring automatic apparatus

A traction substation, bus voltage technology, applied in the direction of measuring devices, instruments, measuring electrical variables, etc., can solve the problems of long recovery time, abnormal bus voltage, large influence range, etc., to achieve convenient site, reasonable design, practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

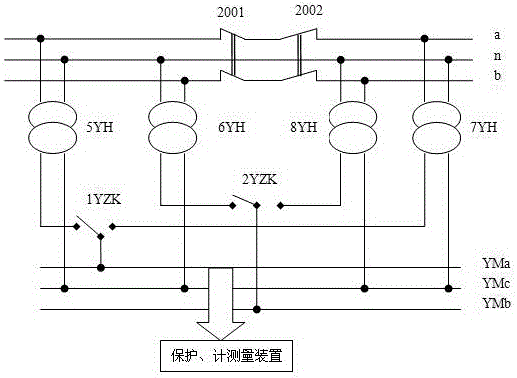

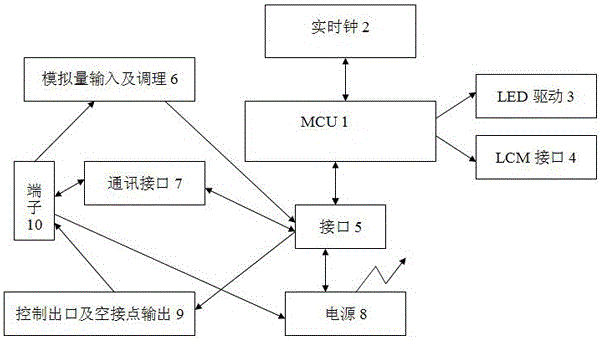

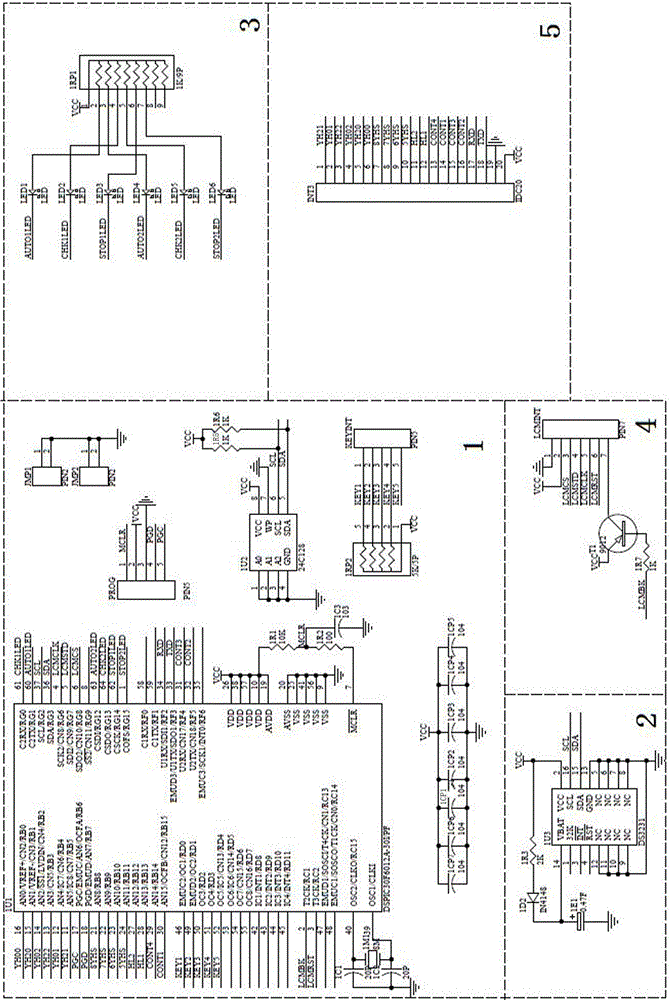

[0023] Such as Figure 2-6 As shown, the automatic device for on-line monitoring of the bus voltage transformer in the traction substation is characterized by: including MCU1, real-time clock 2, LED driver 3, LCM interface 4, two interfaces 5, analog input and conditioning 6, communication interface 7. Power supply 8, control outlet and empty contact output 9 and terminal 10, MCU1, real clock 2, LED driver 3, LCM interface 4 and an interface 5 constitute the main board, analog input and conditioning 6, communication interface 7, power supply 8, Control outlet and empty contact output 9, terminal 10 and another interface 5 form an input and output board; MCU1 uses a 16-bit single-chip microcomputer with data co-processing function as the CPU, and its built-in 12-bit AD converter is used to complete the data sampling function of the device , the CPU is connected to the clock chip and the data memory through the I2C bus; the real clock 2 adopts the clock chip integrated with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com