CCD wire rod detection mechanism

A detection mechanism and wire rod technology, applied in the direction of material analysis, material analysis through optical means, and measuring devices, etc., can solve the problems of low inspection efficiency, increased labor costs, and large shipments, so as to ensure the delivery rate of good products , reduce manpower, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

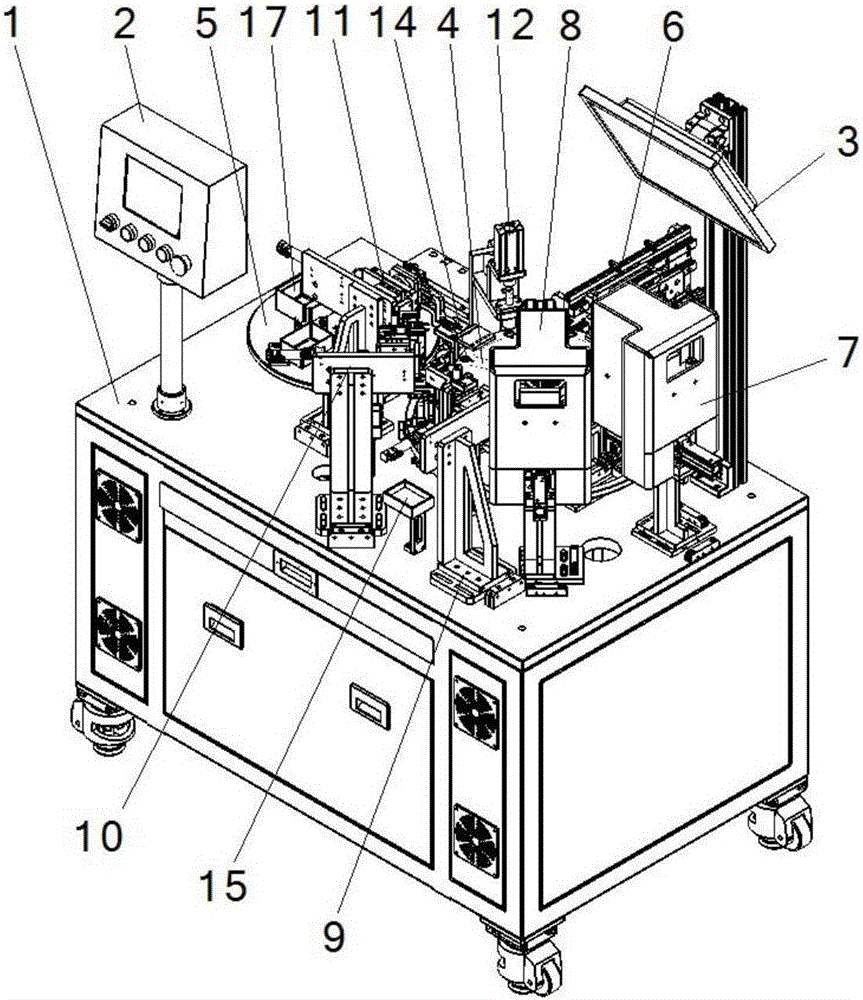

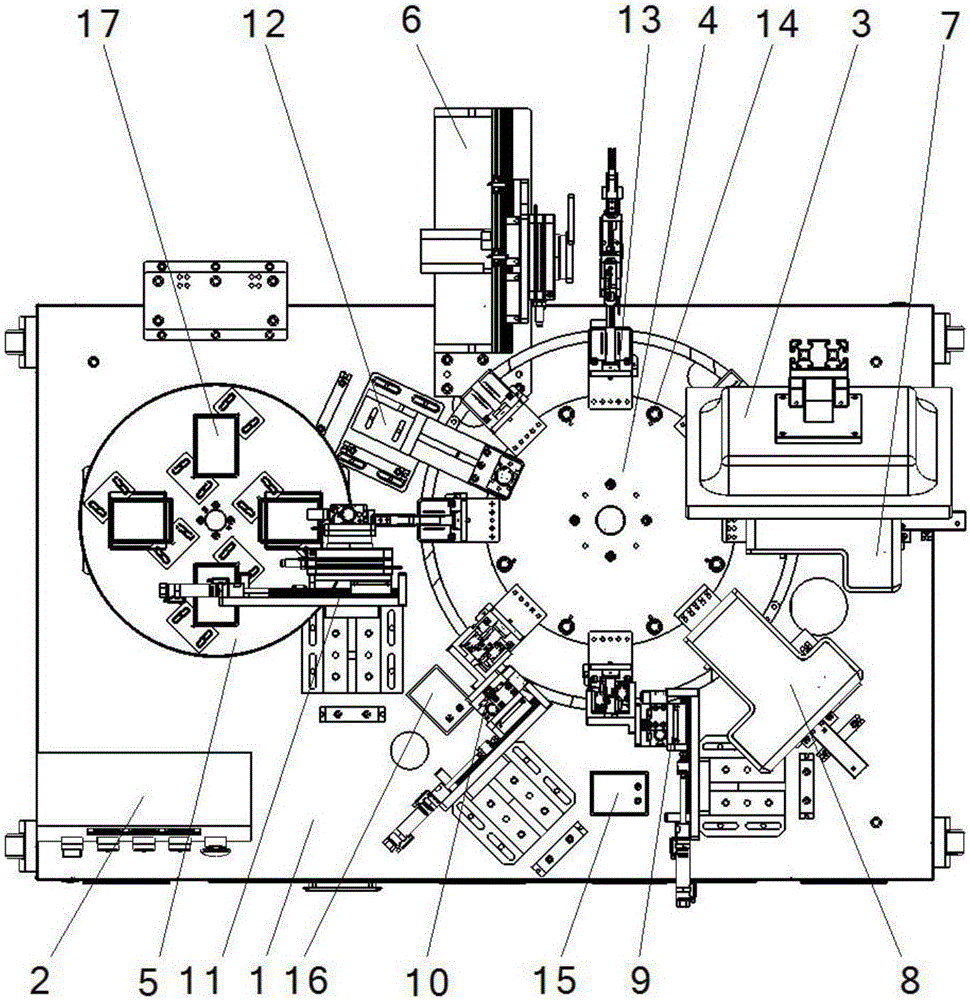

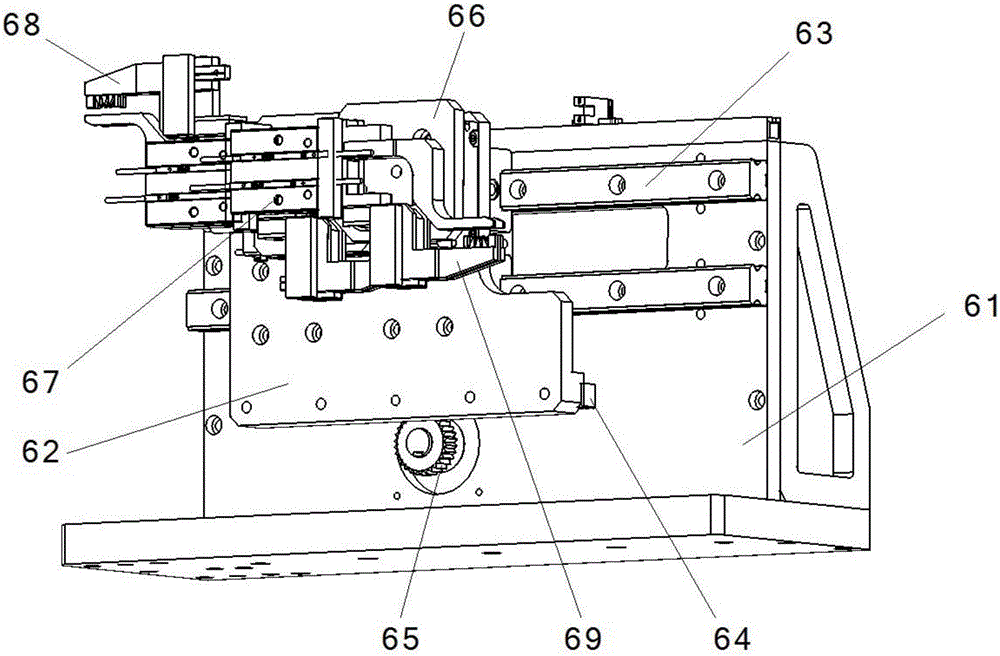

[0023] Such as Figure 1 to Figure 7 As shown, the CCD wire rod inspection mechanism includes a workbench 1; the workbench 1 is provided with a detection turntable 4 and a finished product collection tray 5; the surrounding of the detection turntable 4 is sequentially provided with a reclaiming mechanism 6, The first CCD detection mechanism 7, the second CCD detection mechanism 8, the first defective product rejection mechanism 9, the second defective product rejection mechanism 10, the finished product receiving mechanism 11 and the detection disc positioning mechanism 12; the detection turntable 4 is provided with The positioning hole 14 is used to cooperate with the detection disc positioning mechanism 12; the first defective product collection box 15 is arranged near the first defective product removal mechanism 9; the second defective product removal mechanism 10 is provided with a second Defective product collection box 16; the finished product receiving tray 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com