Heating furnace waste heat comprehensive utilization system and method

A heating furnace and waste heat technology, applied in lighting and heating equipment, chemical instruments and methods, furnaces, etc., can solve the problems of small steam flow, unsuitable use of steam turbines, large fluctuations, etc., and achieve low process cycle power consumption, The effect of significant social and economic benefits and low pretreatment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

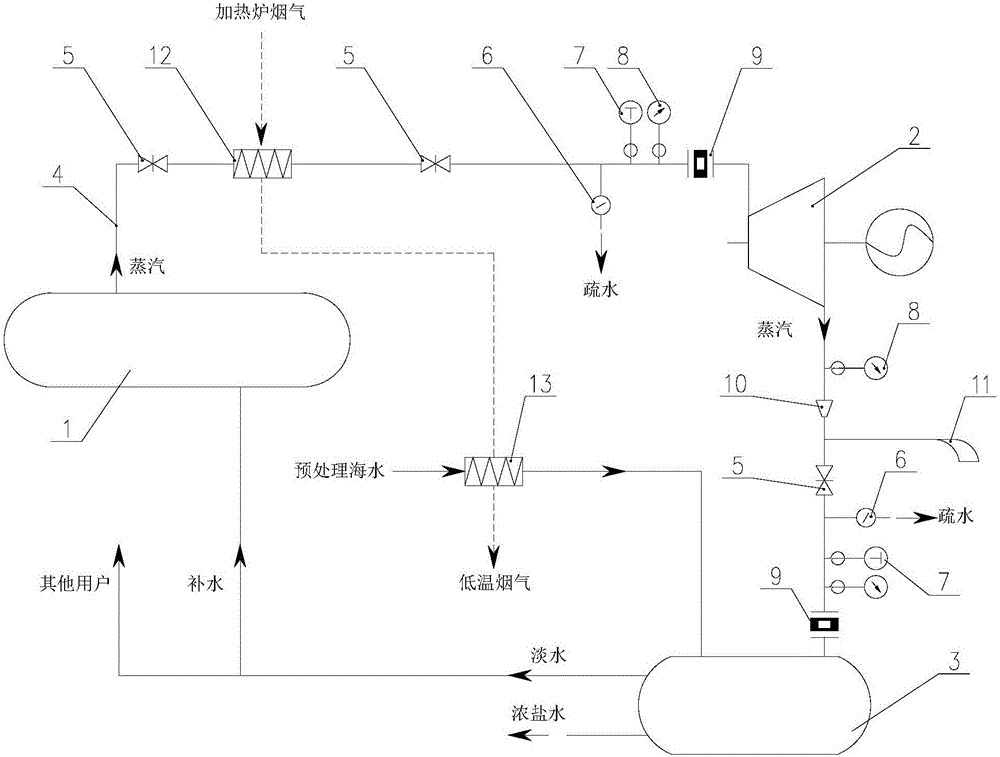

[0048] For a heating furnace with a rated output of 180t / h, the exhaust gas temperature at the furnace tail is about 700°C. An air heat exchanger is installed in the flue of the heating furnace. The flue gas passes through the air heat exchanger to preheat the combustion-supporting air. The temperature of the flue gas after the heat exchanger It is about 450°C. The rated saturated steam output of heating furnace vaporization cooling system 1 is 5.5t / h, and the steam pressure is 0.9MPa(G).

[0049] A steam superheater 12 is installed after the air heat exchanger, and the flue gas temperature after the steam superheater 12 is 2 , MgO, Al 2 o 3 and a small amount of Fe 2 o 3 , the pH value is greater than 7, it is weakly alkaline, the blast furnace slag flushing water has a large amount of water, and the pH value fluctuation range is small, and it is suitable for neutralization treatment with acidic concentrated brine.

[0050] The steam generated by the heating furnace vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com