Mothproof and mosquito-proof light wood-plastic plate

A technology of wood-plastic board and mosquito quality, which is applied in the field of wood-plastic board, can solve the problems of easy moth, easy to be damp and uplift, bad smell, etc., and achieve the effect of strong mechanical strength, enhanced strength and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The board body 1 is prepared from the following raw materials in parts by weight: 30 parts of PVC resin, 25 parts of poplar wood powder, 20 parts of activated calcium carbonate, 3 parts of AC foaming agent, 4 parts of rare earth calcium zinc composite stabilizer, 1 part of polyethylene wax, 0.1 part of natural camphor wood powder.

Embodiment 2

[0028] The board body 1 is prepared from the following raw materials in parts by weight: 35 parts of PVC resin, 30 parts of poplar wood powder, 25 parts of activated calcium carbonate, 4 parts of AC foaming agent, 4.5 parts of rare earth calcium zinc composite stabilizer, 1.2 parts of polyethylene wax, 0.3 parts of natural camphor wood powder.

Embodiment 3

[0030] The board body 1 is prepared from the following raw materials in parts by weight: 40 parts of PVC resin, 35 parts of poplar wood powder, 30 parts of activated calcium carbonate, 5 parts of AC foaming agent, 5 parts of rare earth calcium zinc composite stabilizer, 1.5 parts of polyethylene wax, 0.5 parts of natural camphor wood powder.

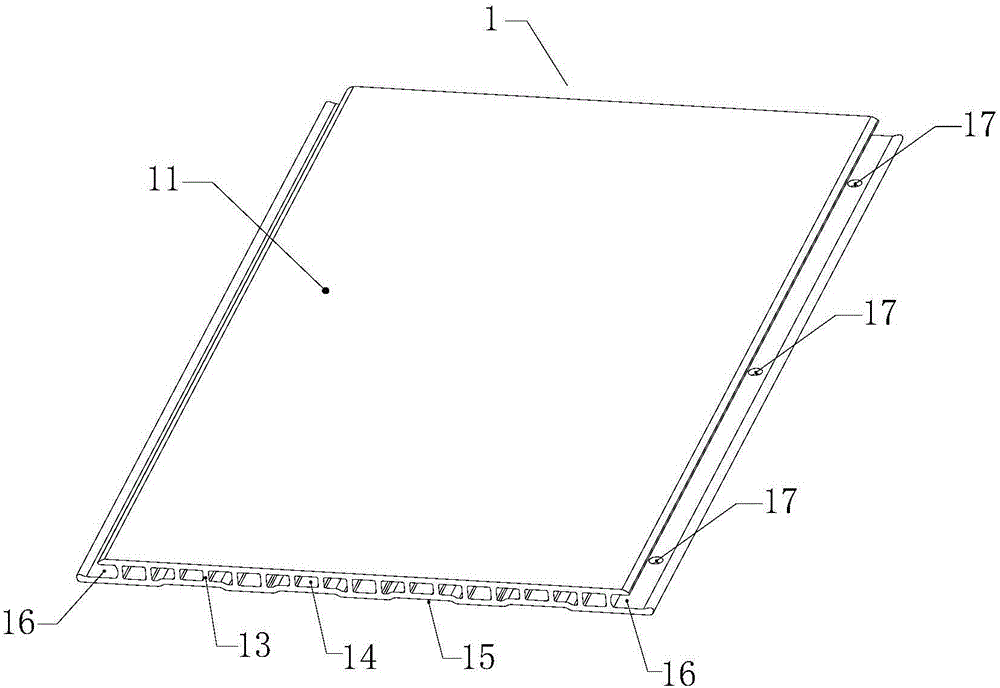

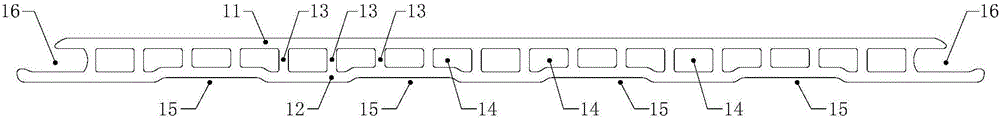

[0031] The moth-proof and mosquito-proof wood-plastic board provided by the present invention has a reasonable structure, and a hollow structure is formed by a flat plate 11, a concave-convex board 12 and a reinforcing rib 13, which is light in weight and high in strength. The concave-convex board 12 is provided with moisture-proof concave Groove 15 can prevent wood-plastic boards from easily bulging after being damp, resulting in uneven board surfaces. The whole board body 1 uses PVC resin, poplar wood powder and active calcium carbonate as main raw materials. The strength, corrosion resistance, and wear resistance of the plastic board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com