Calcium carbonate and aluminum magnesium composite flame-retardant paper, and preparation method thereof

A nano-composite, calcium carbonate technology, applied in the direction of paper, papermaking, paper machines, etc., can solve the problems of increasing process complexity, burning phenomenon, and high cost of flame-retardant paper preparation, and achieve non-toxic and flame-retardant preparation process Significant effect, avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

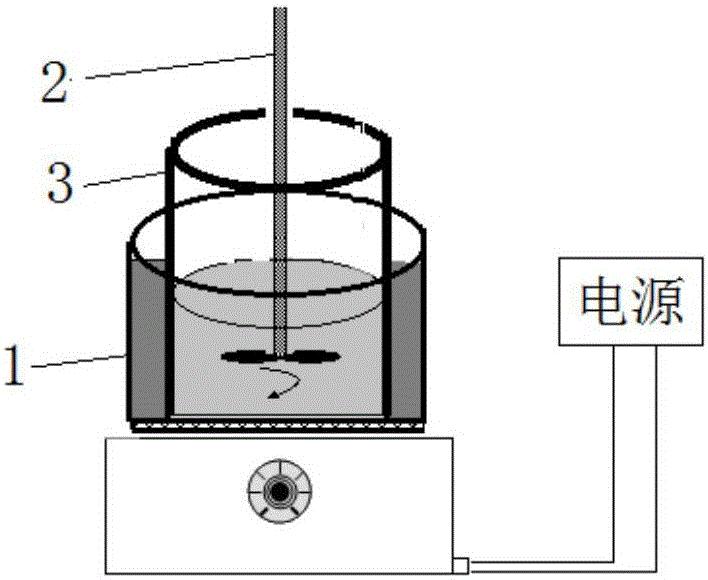

Method used

Image

Examples

Embodiment 1

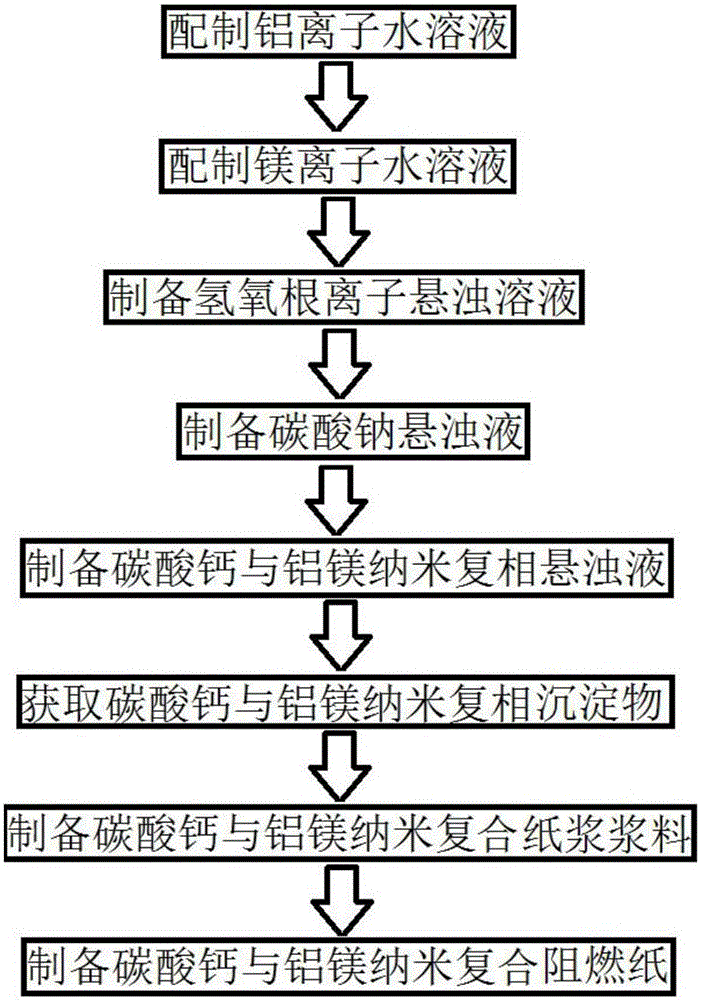

[0085] Example 1, preparing a composite flame-retardant paper containing 12.3% calcium carbonate and 87.7% aluminum-magnesium nanocrystals in nanocomposite precipitates.

[0086] The first step is to configure an aluminum ion aqueous solution.

[0087] 31.395 g of AlCl 3 ·6H 2 O, 30.42 grams of Al 2 (CO 3 ) 3 and 10.66 g of NaAlO 2 Dissolve in 500ml of deionized water and mix to prepare an aluminum ion aqueous solution with a concentration of 0.78mol / L, and filter to remove impurities in the aluminum ion aqueous solution.

[0088] The second step is to configure the magnesium ion aqueous solution.

[0089] 36.4 g of MgSO 4 , 44.89 grams of Mg (NO 3 ) 2 and 28.82 grams of MgCl 2 Dissolve in 500ml deionized water and mix to prepare a magnesium ion aqueous solution with a concentration of 1.82mol / L, and filter to remove impurities in the magnesium ion aqueous solution.

[0090] The third step is to prepare hydroxide ion suspension solution.

[0091] 132.14 grams of Na...

Embodiment 2

[0106] Example 2, preparing a composite flame-retardant paper containing 6.5% calcium carbonate and 93.5% aluminum-magnesium nanocrystals in nanocomposite precipitates.

[0107] Step 1, 10.06 grams of AlCl 3 ·6H 2 O, 9.75 grams of Al 2 (CO 3 ) 3 and 3.42 g of NaAlO 2 Dissolve in 500ml deionized water and mix to prepare an aluminum ion aqueous solution with a concentration of 0.25mol / L, and filter to remove impurities in the aluminum ion aqueous solution;

[0108] Step 2, 11.68 grams of MgSO 4 , 14.41 grams of Mg(NO 3 ) 2 and 9.25 grams of MgCl 2 Dissolve in 500ml deionized water and mix to prepare a magnesium ion aqueous solution with a concentration of 0.584mol / L, and filter to remove impurities in the magnesium ion aqueous solution;

[0109] Step 3, 45.2 grams of NaOH and 5.23 grams of Ca(OH) 2 Dissolve in 500ml deionized water and mix to prepare a hydroxide ion suspension with a concentration of 2.4mol / L;

[0110] Step 4, 19.1 grams of Na 2 CO 3 Dissolve in 500...

Embodiment 3

[0115]Example 3, preparing a composite flame-retardant paper containing 5% calcium carbonate and 95% aluminum-magnesium nanocrystals in nanocomposite precipitates.

[0116] Step A, configure aluminum ion aqueous solution.

[0117] 7.245 g of AlCl 3 ·6H 2 O, 7.02 grams of Al 2 (CO 3 ) 3 and 2.46 g of NaAlO 2 Dissolve in 500ml of deionized water and mix to prepare an aluminum ion aqueous solution with a concentration of 0.18mol / L, and filter to remove impurities in the aluminum ion aqueous solution.

[0118] Step B, configure magnesium ion aqueous solution.

[0119] 8.4 g of MgSO 4 , 10.36 grams of Mg(NO 3 ) 2 and 6.65 grams of MgCl 2 Dissolve in 500ml deionized water and mix to prepare a magnesium ion aqueous solution with a concentration of 0.42mol / L, and filter to remove impurities in the magnesium ion aqueous solution.

[0120] Step C, preparing hydroxide ion suspension.

[0121] 30.5 grams of NaOH and 3.53 grams of Ca(OH) 2 Dissolve in 500ml deionized water and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com