Soluble polyimide film having flame retardancy and preparation method

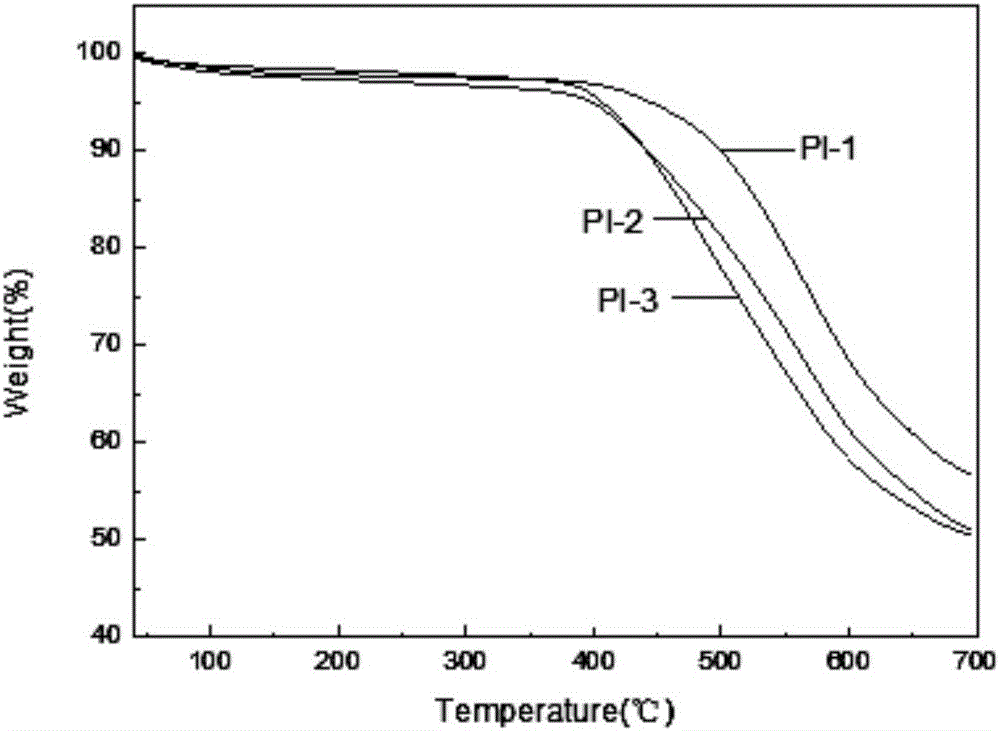

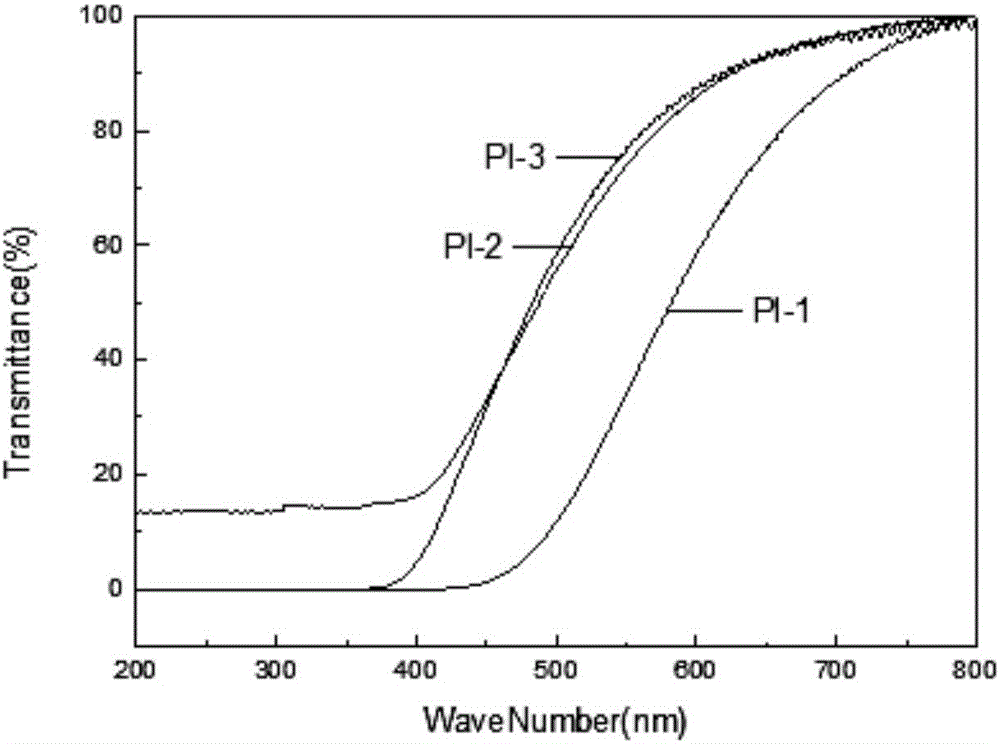

A technology of soluble polyimide film and flame retardancy, which is applied in the field of soluble polyimide film and preparation, can solve the problem of poor heat resistance, achieve improved solubility and flame retardancy, and good flame retardancy performance, the effects of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

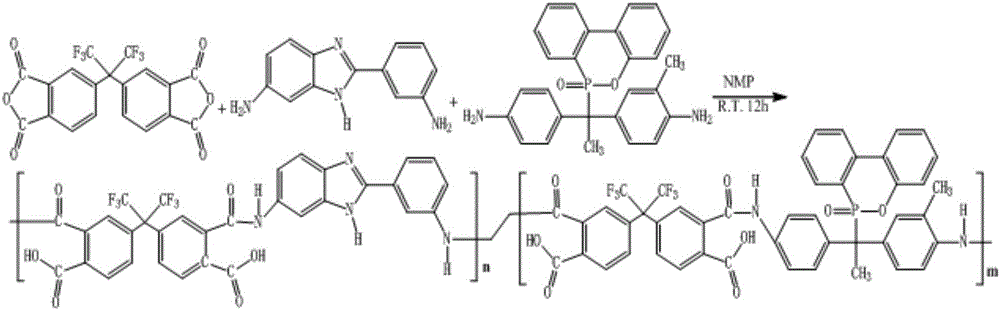

Method used

Image

Examples

Embodiment 1

[0041]1) Clean all the glass instruments to be used in the experiment and dry them for later use;

[0042] 2) Add 0.3522g (0.8mmol) 4-aminophenyl-3-methyl-4-aminophenyl-9,10-dihydro-9- Oxa-10-phosphaphenanthrene-10-phosphoryl ethane (AMADOPPE) and 0.7176g (3.2mmol) 2-(3-aminophenyl)-5-aminobenzimidazole (i-DAPBI) and 12.9688g ( 131mmol) N-methylpyrrolidone (NMP) solvent, stir until AMADOPPE and i-DAPBI are completely dissolved; after the dissolution is complete, use an ice-water bath to lower the temperature of the reaction system to between 10 and 15°C, and pour it into a three-necked flask within 1h Add 1.7770g (4mmol) 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6-FDA), the total solid content is 18% (the total solid content is the sum of the two diamine monomers and the dianhydride weight, Compared to the sum of two diamine monomers, dianhydride and solvent); after the addition, keep the temperature of the reaction system between 10-15°C and react for 12 hours to o...

Embodiment 2

[0045] 1) Clean all the glass instruments to be used in the experiment and dry them for later use;

[0046] 2) Add 0.8565g (2mmol) 4-aminophenyl-3-methyl-4-aminophenyl-9,10-dihydro-9-oxo to a 250mL three-necked flask equipped with a mechanical stirring rod and a nitrogen protection device Hetero-10-phosphaphenanthrene-10-phosphoryl ethane (AMADOPPE) and 0.4485g (2mmol) 2-(3-aminophenyl)-5-aminobenzimidazole (i-DAPBI) and 14.0402g (142mmol) N-methylpyrrolidone (NMP) solvent, stir until AMADOPPE and i-DAPBI are completely dissolved; after the dissolution is complete, use an ice-water bath to lower the temperature of the reaction system to between 10 and 15°C, and add 1.7770g to the three-necked flask within 1h (4mmol) 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6-FDA), the total solid content is 18% (the total solid content is the sum of two kinds of diamine monomers and dianhydride weight, compared to The sum of two diamine monomers, dianhydride and solvent); after the...

Embodiment 3

[0049] 1) Clean all the glass instruments to be used in the experiment and dry them for later use;

[0050] 2) Add 1.4087g (3.2mmol) 4-aminophenyl-3-methyl-4-aminophenyl-9,10-dihydro-9- Oxa-10-phosphaphenanthrene-10-phosphoryl ethane (AMADOPPE) and 0.1794g (0.8mmol) 2-(3-aminophenyl)-5-aminobenzimidazole (i-DAPBI) and 15.3326g ( 155mmol) N-methylpyrrolidone (NMP) solvent, stir until AMADOPPE and i-DAPBI are completely dissolved; after the dissolution is complete, use an ice-water bath to lower the temperature of the reaction system to between 10 and 15°C, and add it to the three-necked flask within 1h 1.7770g (4mmol) 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6-FDA), the total solid content is 18% (the total solid content is the sum of the weights of the two diamine monomers and dianhydrides, which correspond to than the sum of two diamine monomers, dianhydride and solvent); after the addition, keep the temperature of the reaction system at 10-15°C and react for 12 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com