Single-grading-particle-size steel slag permeable asphalt mixture

A permeable asphalt, single-graded technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems that affect the anti-skid performance of the road surface and driving safety, high noise, and affect the ground ecosystem. Achieve the effect of realizing high value-added reuse, protecting the geological environment, and enriching application channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

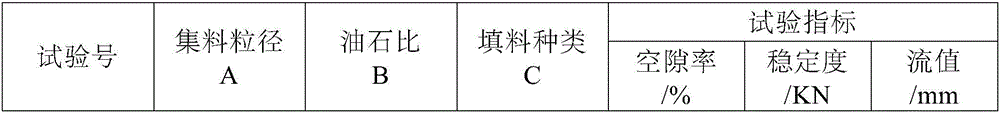

Image

Examples

Embodiment 1

[0020] Prepare 2.36-4.75mm single-graded steel slag particle aggregates and four kinds of fillers: steel slag micropowder, fly ash, cement, and rock mineral powder for backup;

[0021] Based on the total weight of a Marshall test piece as 100%, weigh steel slag particle aggregates with a gradation specification of 2.36 to 4.75 mm, weigh 86.14%, 85.88%, 85.62%, and 85.35% of the steel slag particle aggregates, and weigh them with 7.5 % of fillers (steel slag powder, rock mineral powder, fly ash and composite cement) were mixed, dried in an oven at 170°C to constant weight, poured into the mixing equipment, and added 0.3% high modulus agent Stir evenly for 180s, then add 6.06%, 6.32%, 6.58% and 6.85% rubber asphalt respectively, and mix evenly for 180s.

[0022] The above-mentioned steel slag is obtained from the refractory material discharged from the converter steel slag of Shaanxi Longgang Co., Ltd. after being aged for one year under natural conditions through preliminary gr...

Embodiment 2

[0024] Prepare 4.75-9.5mm gradation steel slag particle aggregates and four kinds of fillers: steel slag micropowder, fly ash, cement, and rock mineral powder, for backup;

[0025] Taking the total weight of a Marshall test piece as 100%, weigh steel slag particle aggregates with a gradation specification of 4.75 to 9.5 mm, weigh 86.14%, 85.88%, 85.62%, and 85.35% of the steel slag particle aggregates, and weigh them with 7.5 % of fillers (rock ore powder, steel slag powder, composite cement and fly ash) were mixed, dried in an oven at 170°C to constant weight, poured into the mixing equipment, and added 0.3% of high modulus agent Stir evenly for 180s, then add 6.06%, 6.32%, 6.58% and 6.85% rubber asphalt respectively, and mix evenly for 180s.

[0026] The above-mentioned steel slag is obtained from the refractory material discharged from the converter steel slag of Shaanxi Longgang Co., Ltd. after being aged for one year under natural conditions through preliminary grinding i...

Embodiment 3

[0028] Prepare steel slag granular aggregates with 9.5-13.2mm gradation specifications and four kinds of fillers, steel slag micropowder, fly ash, cement, and rock ore powder for backup;

[0029] Taking the total weight of a Marshall specimen as 100%, weigh the 9.5-13.2mm gradation specification steel slag granular aggregates, respectively weigh 86.14%, 85.88%, 85.62%, 85.35% of the steel slag granular coarse aggregates, and mix them with 7.5% of fillers (fly ash, composite cement, steel slag powder and rock ore powder) are mixed, dried in a 170°C oven to constant weight, poured into the mixing equipment, and added with 0.3% high modulus The agent was uniformly mixed for 180s, and then 6.06%, 6.32%, 6.58% and 6.85% of rubber asphalt were added respectively, and the mixture was uniformly mixed for 180s.

[0030] The above steel slag is made from the refractory steel slag of Shaanxi Longgang Company after being aged for one year under natural conditions, and its apparent relativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com