Acid gun lifting device with monitoring and protection functions

A technology of lifting device and protective function, which is applied in the field of acid regeneration by spray roasting method, and can solve the problems of loose wire rope, potential safety hazard, and failure to give the working method of the tension detection device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

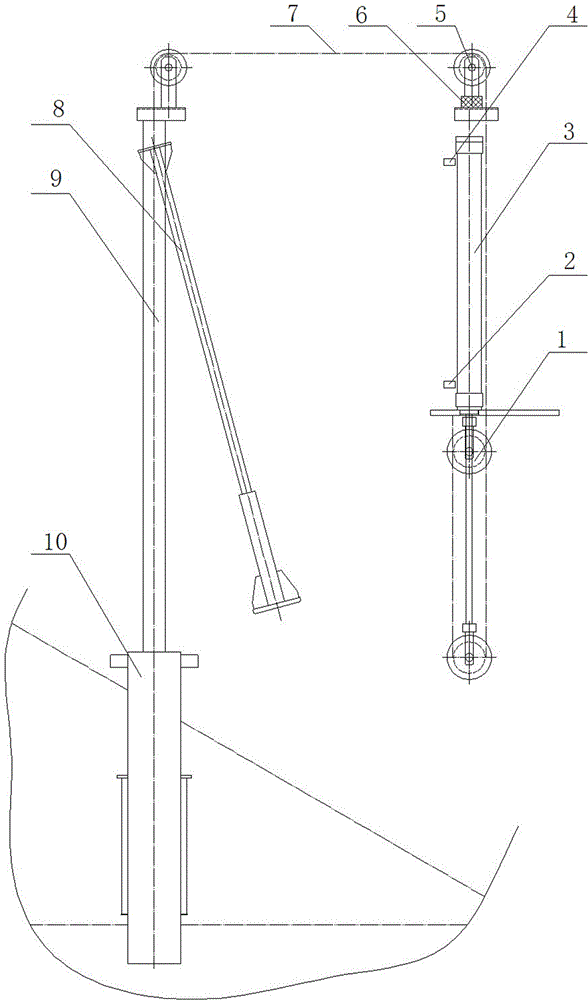

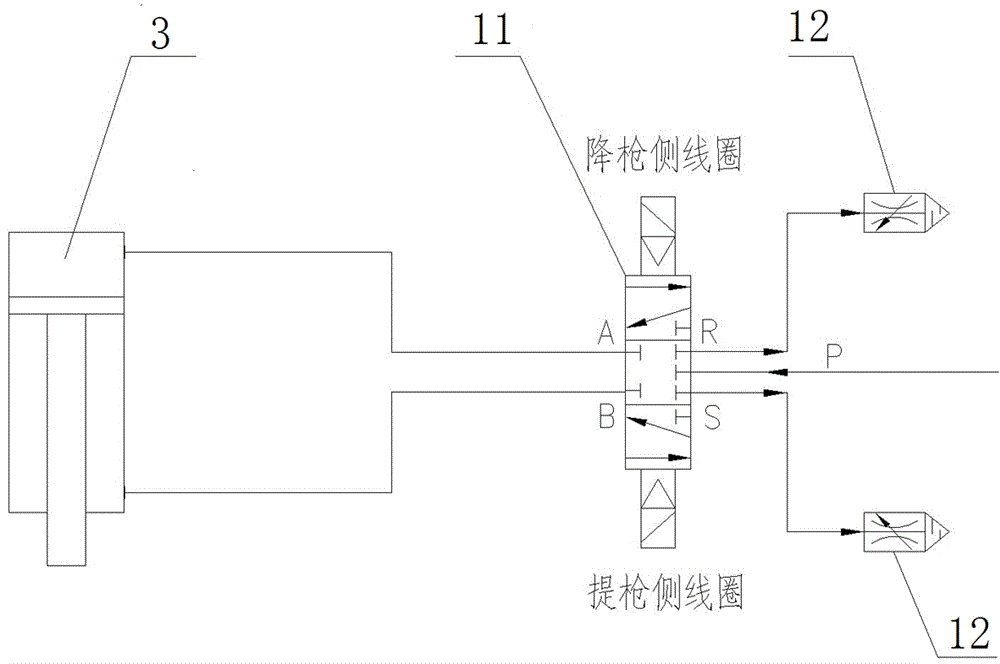

[0016] Such as figure 1 with figure 2 As shown, a kind of acid gun lifting device with monitoring and protection function includes acid gun 8, cylinder 3, steel wire rope 7 and controller, cylinder 3 points downward and cylinder 3 push rod is provided with movable pulley 1, steel wire rope 7 one end and acid The tail of the gun 8 is connected, and the other end passes through the movable pulley 1 and is fixed. Two static pulleys 5 for steering are arranged along the wire rope 7. The tail of the acid gun 8 cooperates with the acid gun slide 9, and the acid gun protective cover is arranged under the head The two ends of cylinder 10 and cylinder 3 stroke are respectively equipped with induction switches (2 and 4), and the induction switches (2 and 4) are connected with the controller. The rod cavity and the rodless cavity are respectively connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com