Induction heating power supply output control system and method

An induction heating power supply and output control technology, applied in the power supply field, can solve the problem of frequent output jitter in the power supply system, and achieve the effects of ensuring fast response and operational reliability, improving stability, and smooth switching and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

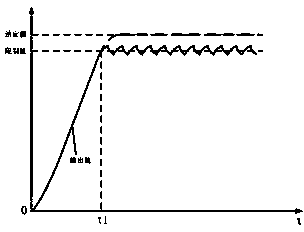

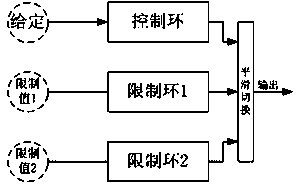

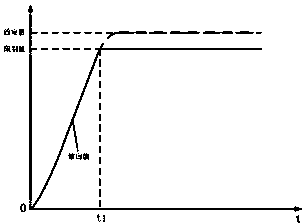

[0020] refer to figure 2 , the output control system of the induction heating power supply of the present invention includes a control loop and a plurality of limiting loops, the number of limiting loops is determined by the limiting conditions, and one limiting condition corresponds to only one limiting loop, and each limiting loop and control loops operate independently In the end, the output results of each loop are judged by the internal program logic of the DSP, and the results that meet all the restrictive conditions are selected for output control. The induction heating powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com