Plate material, multilayer composite plate material with plate material, and preparation method of plate material

A multi-layer composite and plate technology, applied in the field of structural materials, can solve the problems of poor performance, impact resistance and fatigue resistance, low sound insulation and heat insulation effect, peeling of panels and core materials, etc., to improve impact resistance and fatigue resistance. , to achieve the effect of light weight and load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

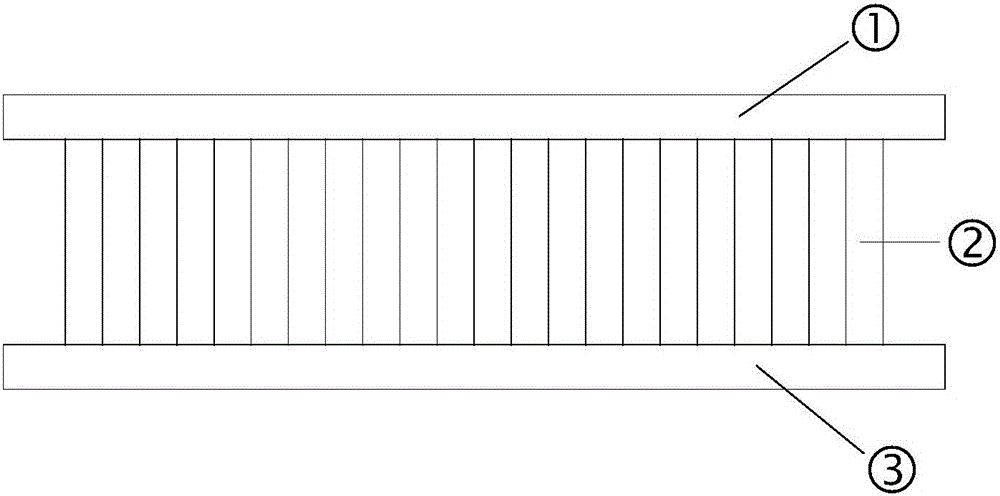

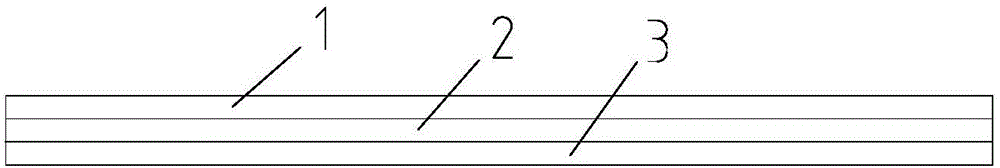

[0040] Specific embodiment one: see figure 2 , a sheet material, the sheet material is a multi-layer composite formed by hot-pressing an aluminum alloy layer 1, a prepreg layer 2 made of a mixture of glass fiber and epoxy resin, and an aluminum alloy layer 3 from top to bottom plate.

[0041] In this embodiment, the content of the epoxy resin in the prepreg layer is 30wt%, which is beneficial to the impregnation of the glass fiber with the epoxy resin.

[0042] In this embodiment, in order to further enhance the stress bearing capacity of the plate, the glass fiber is a high-strength glass fiber with a monofilament strength of 4500 MPa.

[0043] In this embodiment, the thickness of the plate is 0.8mm. In the case of ensuring the bearing capacity of the plate, the light weight of the plate is maintained. Among them, the aluminum alloy layer is made of 2024-T3 aluminum alloy plate with a size of 500mm×500mm×0.3mm. The size of the prepreg layer is 500mm×500mm×0.2mm.

[0044] ...

specific Embodiment 2

[0053] Specific embodiment two: see figure 2 , a sheet material, the sheet material is a multi-layer composite formed by hot-pressing an aluminum alloy layer 1, a prepreg layer 2 made of a mixture of glass fiber and epoxy resin, and an aluminum alloy layer 3 from top to bottom plate.

[0054] In this embodiment, the content of the epoxy resin in the prepreg layer is 40wt%, which is beneficial to the impregnation of the glass fiber with the epoxy resin.

[0055] In this embodiment, in order to further enhance the stress bearing capacity of the plate, the glass fiber is a high-strength glass fiber with a monofilament strength of 5000 MPa.

[0056] In this embodiment, the thickness of the plate is 1.3mm. In the case of ensuring the bearing capacity of the plate, the light weight of the plate is maintained. Among them, the aluminum alloy layer is made of 2024-T3 aluminum alloy plate, and the size is 500mm×500mm×0.5mm. The size of the prepreg layer is 500mm×500mm×0.3mm.

[0057...

specific Embodiment 3

[0066] Embodiment 3: Different from Embodiment 1, in this embodiment, the content of epoxy resin in the prepreg layer is 35wt%, which is beneficial to the impregnation of glass fibers with epoxy resin. In order to further enhance the stress bearing capacity of the plate, the glass fiber adopts a high-strength glass fiber with a monofilament strength of 4800 MPa. The thickness of the board is 1.0mm, and the lightness of the board is kept while ensuring the bearing capacity of the board.

[0067] In the present embodiment, the steps of the preparation method of the plate are as follows:

[0068] (1) The surface of the aluminum alloy is anodized with complex acid to form a uniform oxide film on the surface of the aluminum alloy, and the surface of the aluminum alloy is coated with butadiene primer within 24 hours;

[0069] (2) drying the prepreg and the aluminum alloy treated in step (1) to remove the solvent;

[0070] (3) Lay the plates in the order of aluminum alloy, prepreg,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com