Flue gas purifying system

A flue gas purification system and flue gas purification technology are applied in the direction of gas treatment, chemical instruments and methods, combined devices, etc., which can solve the problems of inconvenient recovery by semi-comprehensive methods, fast pollution of excreta, and low recycling efficiency. Achieve the effect of saving installation time, small equipment size and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

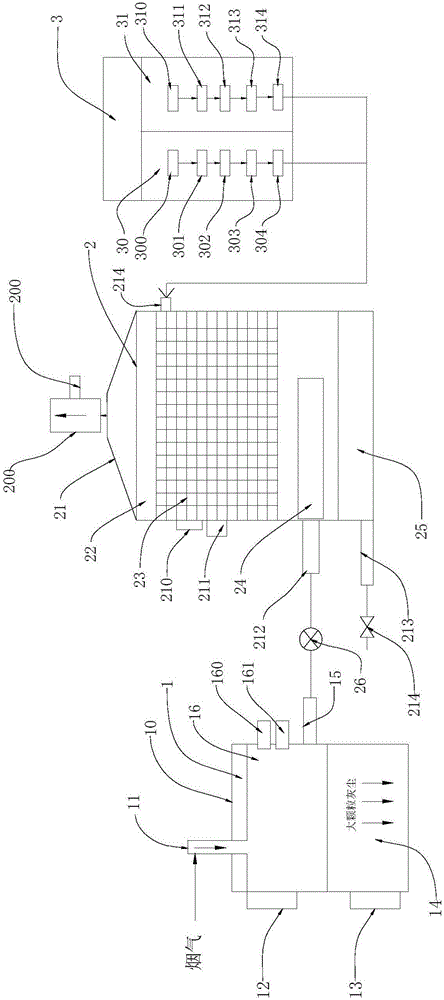

[0035] see figure 1 and image 3 , The flue gas purification system of this embodiment includes a cold and heat exchange unit 1 for flue gas cooling, a flue gas purification unit 2, and a chemical dosing unit 3 for adding additives and reactants to the flue gas purification unit 2 .

[0036] The cold heat exchange unit 1 includes a cold heat exchange unit housing 10 and a gravity dust removal box 14 and a cold heat exchanger 16 located inside the cold heat exchange unit housing 10, and the cold heat exchanger 16 is located between the gravity dust removal box 14 Above, an air inlet 11 is provided on the upper part of the cooling and heat exchange unit housing 10 , and a thermometer 12 , a liquid level gauge 13 and an air outlet 15 are provided on the side of the cooling and heat exchanging unit housing 10 . The cold heat exchanger 16 is provided with a water inlet 161 and a water outlet 160, the water inlet 161 communicates with an external cold water source pipeline, and th...

Embodiment 2

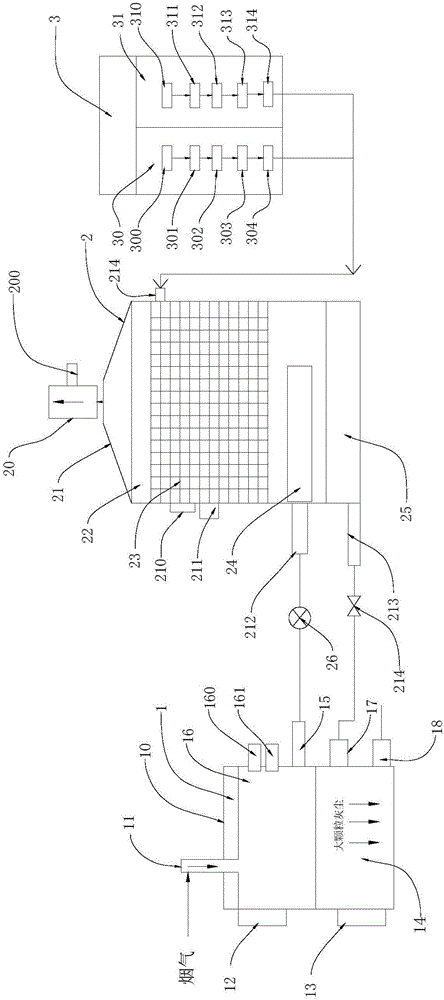

[0048] see figure 2 and image 3 , on the basis of Embodiment 1, a mixed liquid dust removal inlet 17 and a mixed liquid dust removal outlet 18 communicating with the gravity dust removal box 14 are added to the side wall of the cold and heat exchange unit housing 10, and the outlet of the valve 214 is connected to the mixed liquid dust removal inlet 17 . In this way, during the flue gas purification process, the mixed liquid enters the gravity dust removal box 14 through the mixed liquid dust removal inlet 17 , and is discharged from the mixed liquid dust removal outlet 18 after washing the gravity dust removal box 14 .

[0049] Compared with Embodiment 1, this embodiment adds a channel for the mixed liquid to flush the gravity dust removal box 14, which can realize the online scrubbing and cleaning of the gravity dust removal box 14, saves the workload of manual cleaning, and improves the whole flue gas treatment at the same time. system work efficiency.

[0050] Similar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com