Developing type degradable restoration pancreatic duct bracket

A pancreatic duct and contrast agent technology, applied in the field of developing degradable pancreatic duct stents, can solve the problems of inability to understand the shape and position of implanted materials, vulnerable tissue of patients, low electron density, etc., and achieve controllable degradation time. , reduce scarring, promote healing and repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

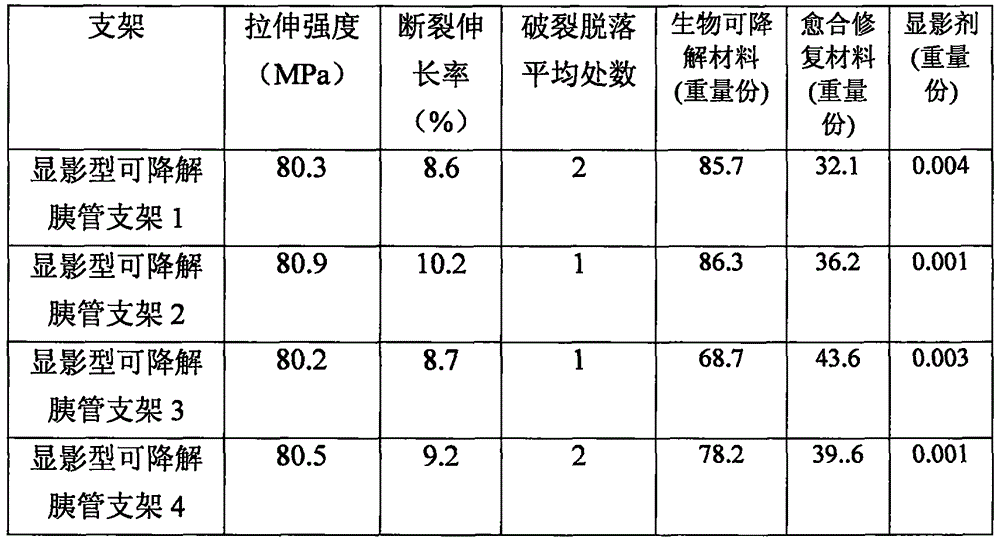

Examples

Embodiment 1

[0057] Example 1 Preparation method of developing-type degradable repair of pancreatic duct

[0058] Extrusion threaded pipe: Extrusion complete set of equipment includes extruder, traction device, sizing device, cooling device and supporting equipment. Extrusion temperature: 150°C. The extrusion material is a biodegradable material: polylactic acid-polyglycolic acid copolymer (PLGA). The pitch of the thread groove is: 10mm.

[0059] Cooling: cooling by air cooling.

[0060] Guachuang coating: through automatic dispensing machine and other equipment, glue is applied to the spiral groove of the outer wall of the threaded pipe, dried, washed with absolute ethanol, dried, and the healing and repairing functional material is a colloid solution made of polysaccharide .

[0061] The preparation method of the healing and repairing functional material is as follows: weigh 50g of chitosan powder, put it into a glass reaction vessel, add 130mL of propionic anhydride solution of acyl...

Embodiment 2

[0069] Example 2 Preparation method of developing-type degradable repair of pancreatic duct

[0070] Extrusion threaded pipe: Extrusion complete set of equipment includes extruder, traction device, sizing device, cooling device and supporting equipment. Extrusion temperature: 150°C. The extrusion material is a biodegradable material: polylactic acid-polyglycolic acid copolymer (PLGA). The pitch of the thread groove is: 10mm.

[0071] Cooling: cooling by air cooling.

[0072] Guachuang coating: through automatic dispensing machine and other equipment, glue is applied to the spiral groove of the outer wall of the threaded pipe, dried, washed with absolute ethanol, dried, and the healing and repairing functional material is a colloid solution made of polysaccharide .

[0073] The preparation method of the healing and repairing functional material is as follows: weigh 50g of chitosan powder, put it into a glass reaction vessel, add 130mL of propionic anhydride solution of acyl...

Embodiment 3

[0081] Example 3 Preparation method of developing-type degradable repair of pancreatic duct

[0082] Extrusion threaded pipe: Extrusion complete set of equipment includes extruder, traction device, sizing device, cooling device and supporting equipment. Extrusion temperature: 150°C. The extrusion material is a biodegradable material: polylactic acid-polyglycolic acid copolymer (PLGA). The pitch of the thread groove is: 10mm.

[0083] Cooling: cooling by air cooling.

[0084] Guachuang coating: through automatic dispensing machine and other equipment, glue is applied to the spiral groove of the outer wall of the threaded pipe, dried, washed with absolute ethanol, dried, and the healing and repairing functional material is a colloid solution made of polysaccharide .

[0085] The preparation method of the healing and repairing functional material is as follows: weigh 50g of chitosan powder, put it into a glass reaction vessel, add 130mL of propionic anhydride solution of acyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com