A kind of multi-stage porous hydrocracking catalyst and its application

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, hydrocarbon oil cracking, etc., can solve problems affecting catalyst pore distribution, metal carrier interaction changes, and reducing active hydroxyl groups on the surface of alumina precursors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

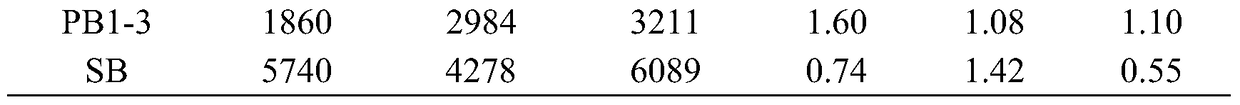

[0054] 298 grams of pseudo-boehmite SB (dry basis 0.75, dry basis measurement method is to put a certain amount of raw powder into a crucible with a lid into the muffle furnace, heat up to 700 ℃ constant temperature for 1 hour, calculate the remainder of the same original The ratio of powder, the same below) and 366.7 grams of ultra-stable molecular sieve LAY (produced by Changling Catalyst Plant of Sinopec Catalyst Branch, unit cell constant 24.58, pore volume 0.39ml / g, dry basis 0.75), sesame powder 16g, 12ml purity Mix 65% concentrated nitric acid and 400ml deionized water evenly, extrude it into a trilobal strip with a circumscribed circle diameter of 1.6 mm, dry at 120°C for 3 hours, and roast at 600°C for 3 hours to obtain a carrier. The composition of the catalyst carrier is shown in Table 2.

[0055] After cooling to room temperature, take 100 grams of carrier containing ammonium metatungstate (Sichuan Zigong Cemented Carbide Factory, the content of tungsten oxide is 82% ...

Embodiment 2

[0057] Mix 298 grams of pseudo-boehmite PB1-2 (0.74 on a dry basis) with 366.7 grams of ultra-stable molecular sieve LAY, 16 grams of sesame powder, 12 ml of 65% concentrated nitric acid, and 482 ml of deionized water. A trilobal strip with a diameter of 1.6 mm was dried at 120°C for 3 hours and calcined at 600°C for 3 hours to obtain a carrier. The composition of the catalyst carrier is shown in Table 2.

[0058] After cooling to room temperature, take 100 grams of carrier containing ammonium metatungstate (Sichuan Zigong Cemented Carbide Factory, the content of tungsten oxide is 82% by weight), 50 grams of basic nickel carbonate (Jiangsu Yixing Xuchi Chemical Co., Ltd., nickel oxide content) (51% by weight) 8.7g, 10.5g of citric acid 78ml aqueous solution were immersed and baked at 180°C for 10 hours to obtain catalyst C-2. Based on the total amount of catalyst, the mass fractions of metal components in C-2 (calculated values, the same below) are listed in Table 2.

Embodiment 3

[0060] Mix 296 grams of pseudo-boehmite PB1-3 (0.76 on a dry basis) with 366.7 grams of ultra-stable molecular sieve LAY, 16 grams of sesame powder, 3.5 ml of 65% concentrated nitric acid, and 700 ml of deionized water. A trilobal strip with a circle diameter of 1.6 mm was dried at 120°C for 3 hours and calcined at 600°C for 3 hours to obtain a carrier. The composition of the catalyst carrier is shown in Table 2.

[0061] After cooling to room temperature, take 100 grams of carrier containing ammonium metatungstate (Sichuan Zigong Cemented Carbide Factory, the content of tungsten oxide is 82% by weight), 50 grams of basic nickel carbonate (Jiangsu Yixing Xuchi Chemical Co., Ltd., nickel oxide content) (51% by weight) 8.7g, 10.5g of citric acid 110ml aqueous solution immersion, 180°C for 10 hours, to obtain catalyst C-2. Based on the total amount of catalyst, the mass fractions of metal components in C-2 (calculated values, the same below) are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com