Switched reluctance motor with 8/9 structure

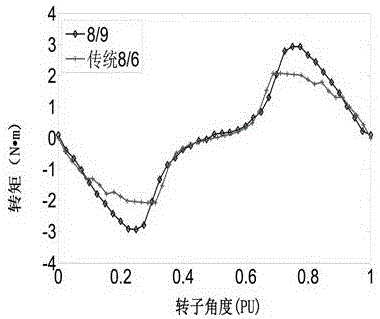

A switched reluctance motor and magnet technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electric components, etc., can solve the problems of motor winding end increase, motor output torque reduction, low utilization rate of iron core, etc. Achieve the effects of low core loss, reduced magnetomotive force, and high electromagnetic utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Attached below Figure 1~4 And to describe the present invention in detail, the following description is only for demonstration and explanation, and does not limit the present invention in any form.

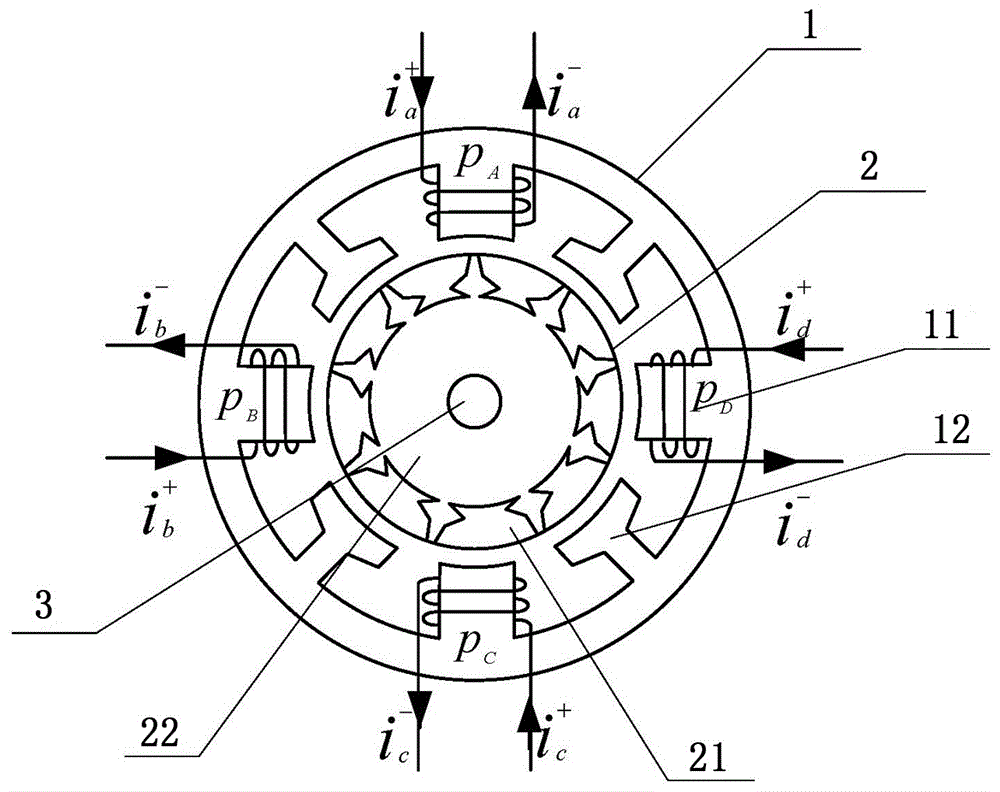

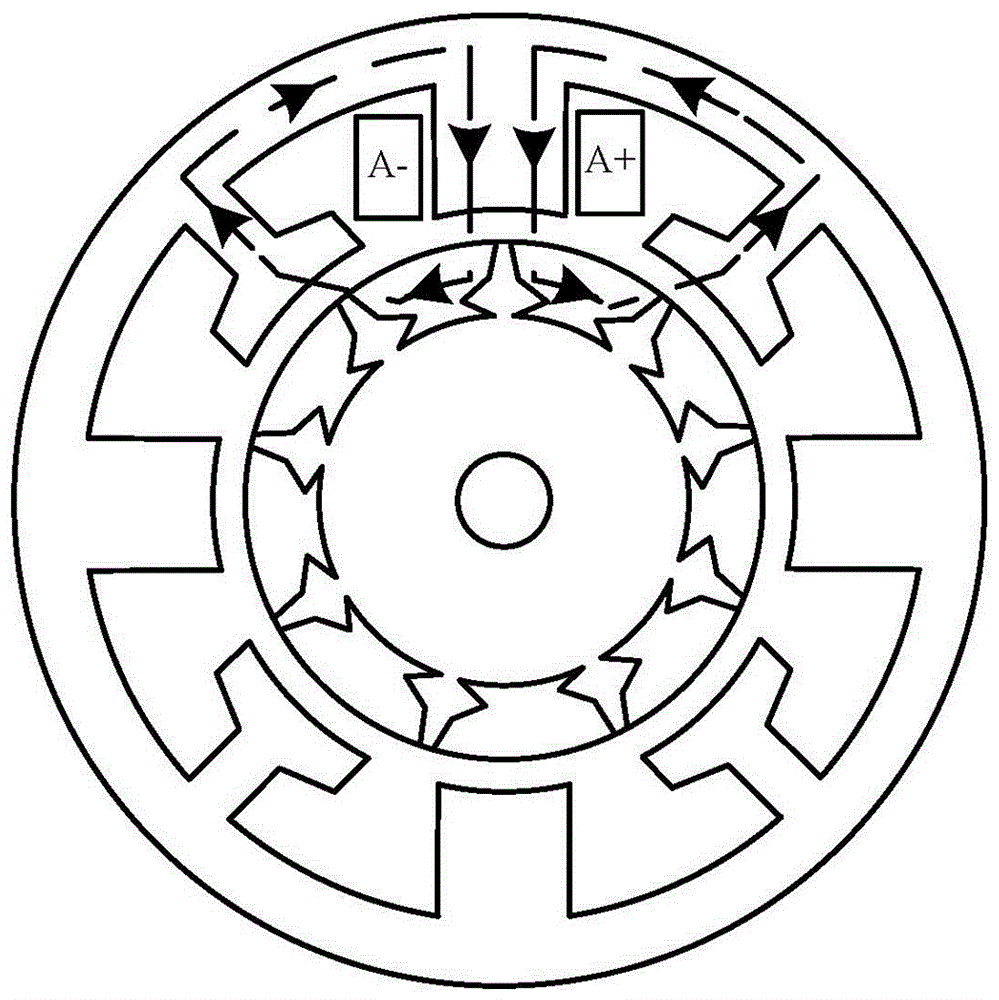

[0013] The technical solution of the present invention is: a switched reluctance motor with an 8 / 9 structure, including a housing, a stator 1 and a rotor 2, wherein the stator 1 is four-phase eight-pole, and the rotor 2 is nine-pole with block In the switched reluctance motor of the rotor, the stator 1 is fixed on the casing, and the stator 1 is alternately provided with excitation poles 11 and auxiliary poles 12, a total of eight, the width of the excitation pole 11 is twice the width of the auxiliary pole 12, and the excitation winding They are separately wound on the four excitation poles of A, B, C, and D. The rotor 2 includes nine independent rotor poles 21 and a non-magnetic conductor 22. Each rotor pole is evenly embedded in the non-magnetic conductor 22, and each i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com