Color cigarette paper coating spice and application method thereof

A cigarette paper and coating technology, which is applied in the process of adding paper coatings, essential oils/flavors, and pulp raw materials, etc., can solve problems such as safety doubts, and achieve the effects of improving safety, optimizing appearance and color, and achieving remarkable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Application in cigarette "H" brand

[0019] (1) Sample making

[0020] Take 0.07 part of gardenia extract, 0.04 part of beet extract, 0.12 part of cocoa extract, 0.05 part of Yunnan tobacco extract, 0.05 part of Zimbabwe tobacco extract, 0.06 part of tea leaf extract, 0.12 part of β-cyclodextrin and 0.03 part of ascorbic acid Parts are mixed to make colored cigarette paper coating flavors. Get 0.5 part of said colored cigarette paper coating flavor and 0.4 part of combustion enhancer (wherein 0.28 part of potassium citrate, 0.12 part of potassium malate) and 9.0 parts of water and mix, the pH value of the mixture is 5.0, and the temperature is controlled at Make cigarette paper samples by coating at 55°C, and then make corresponding cigarette samples.

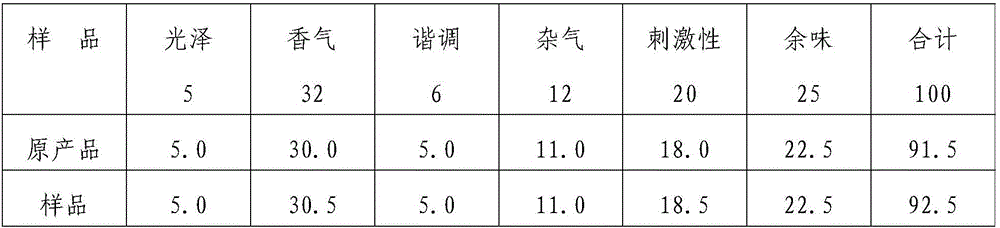

[0021] (2) Implementation effect

[0022] Using Konica Minolta CR-400 colorimeter (Konica Minolta, Japan) to analyze the original large-scale production samples of "H" cigarette paper, the L* value is between 64 and 6...

Embodiment 2

[0028] Application in cigarette "Y" brand

[0029] (1) Sample making

[0030] Take 0.06 part of gardenia extract, 0.05 part of beet extract, 0.20 part of cocoa extract, 0.06 part of Yunnan tobacco extract, 0.10 part of Zimbabwe tobacco extract, 0.06 part of tea leaf extract, 0.15 part of β-cyclodextrin and 0.04 part of ascorbic acid The required color cigarette paper coating flavor is obtained after mixing the parts evenly. Get 0.5 part of the described color cigarette paper coating spice and 0.4 part of combustion enhancer (wherein 0.32 part of sodium citrate, 0.08 part of potassium malate) and 9.0 parts of water are mixed, and the pH value of this moment mixture is 5.5, and temperature Control the coating at 55°C to make cigarette paper samples, and then make corresponding cigarette samples.

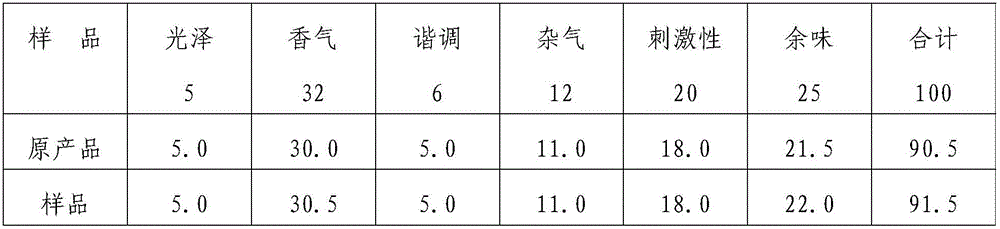

[0031] (2) Implementation effect

[0032] Using Konica Minolta CR-400 colorimeter (Konica Minolta, Japan) to analyze the original mass production samples of "Y" cigarette paper, the...

Embodiment 3

[0037] Application in cigarette "L" brand

[0038] (1) Sample making

[0039] Take 0.08 part of gardenia extract, 0.03 part of beet extract, 0.10 part of cocoa extract, 0.04 part of Yunnan tobacco extract, 0.05 part of Zimbabwe tobacco extract, 0.03 part of tea leaf extract, 0.13 part of β-cyclodextrin and 0.02 part of ascorbic acid Parts are mixed to make colored cigarette paper coating flavors. Get 0.5 part of the color cigarette paper coating spice and 0.4 part of combustion enhancer (wherein 0.28 part of potassium citrate, 0.07 part of sodium citrate, 0.05 part of potassium malate) and mix with 9.0 parts of water. The value is 6.0, and the temperature is controlled at 55°C to coat and make cigarette paper samples, and then make corresponding cigarette samples.

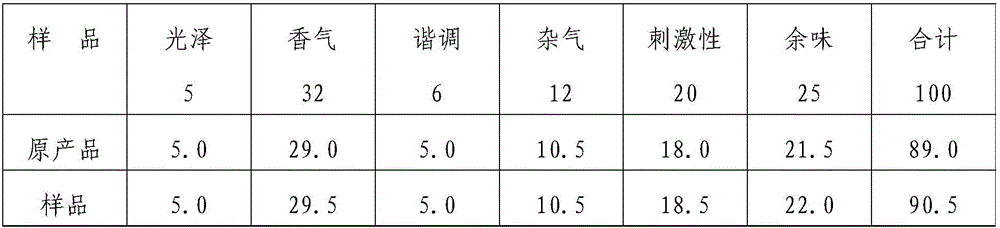

[0040] (2) Implementation effect

[0041] Using Konica Minolta CR-400 colorimeter (Konica Minolta, Japan) to analyze the original large-scale production samples of "L" cigarette paper, the L* value is between 66...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com