Circulation dyeing method for dye wastewater

A technology of dye wastewater and dyeing method, which is applied in the field of cyclic dyeing of dye wastewater, can solve problems such as adverse effects of dyeing, and achieve the effects of simple method, short treatment process and reduced discharge amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

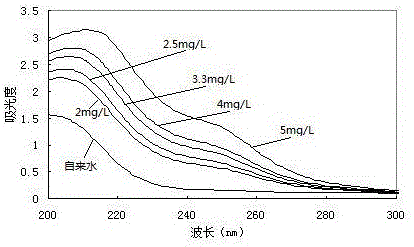

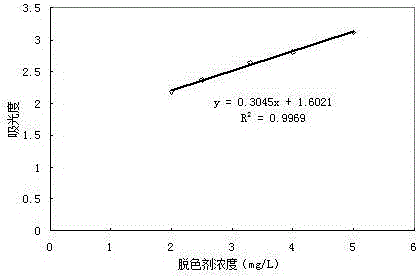

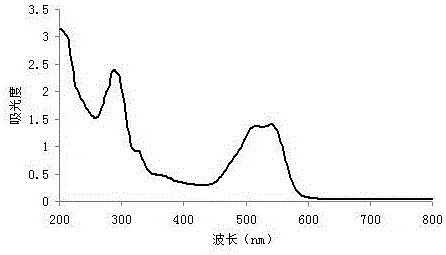

[0029] In this embodiment, red reactive dyes are used to dye wastewater, and the ultraviolet-visible spectral curve of the wastewater in the wavelength range of 200-800nm is as follows: image 3 As shown, adopt the hydrochloric acid of 5% mass concentration to carry out pH titration to this clear liquid, after adjusting pH to be 7~7.5, add the cationic decolorizing agent of 0.123g / L (Guangzhou Zhongbei Environmental Protection Technology Co., Ltd., model Z8- SD), after stirring for 2 minutes, carry out precipitation decolorization, centrifuge for 5 minutes after decolorization is complete, and take the supernatant. Measure the ultraviolet-visible spectral curve of the clear liquid in the wavelength range of 200-800nm, such as Figure 4 As shown, the color influencing factors in the supernatant have basically been removed, and the supernatant is clear and thorough.

[0030] Add the anionic surfactant (the low-molecular-weight copolymer of maleic acid and acrylic acid) of 2g / ...

Embodiment 2

[0037] In this embodiment, yellow reactive dye dyed wastewater is used as the treatment object, and the ultraviolet-visible spectral curve in the wavelength range of 200-800nm of the wastewater is as follows: Figure 5 As shown, adopt the sulfuric acid of 5% mass concentration to carry out pH titration to this clear liquid, adjust the pH to be 7~7.5 after adding the cationic decolorant of 0.142g / L (Guangzhou Zhongbei Environmental Protection Technology Co., Ltd., model Z8-SD ), after stirring for 2 minutes, precipitate and decolorize, centrifuge for 5 minutes after the decolorization is complete, and take the supernatant. Measure the ultraviolet-visible spectral curve of the clear liquid in the wavelength range of 200-800nm, such as Image 6 As shown, the color influencing factors in the supernatant have basically been removed, and the supernatant is clear and thorough.

[0038] Add 1.5g / L of anionic surfactant (alkyl naphthalene sulfonate) and stir for 5min to make the ani...

Embodiment 3

[0044] In this embodiment, blue reactive dyes are used to dye wastewater, and the ultraviolet-visible spectral curve in the 200-800nm wavelength range of the wastewater is as follows: Figure 7 As shown, adopt the sulfuric acid of 5% mass concentration to carry out pH titration to this clear liquid, adjust the pH to be 7~7.5 after adding the cationic decolorant of 0.215g / L in the waste water (Guangzhou Zhongbei Environmental Protection Technology Co., Ltd., model Z8-SD ), after stirring for 2 minutes, precipitate and decolorize, centrifuge for 5 minutes after the decolorization is complete, and take the supernatant. Measure the ultraviolet-visible spectral curve of the clear liquid in the wavelength range of 200-800nm, such as Figure 8 shown.

[0045] Add 1.2g / L of anionic surfactant and stir for 5min to make the anionic surfactant (low molecular copolymer of maleic acid and acrylic acid or anionic surfactant of alkyl naphthalene sulfonate) fully react with cationic decolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com