Metal material melt coating forming device and method

A technology of fusion coating and metal materials, applied in the field of materials, can solve the problems of little research on metal coating and forming technology, and achieve the effects of shortening forming time, strong operability and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

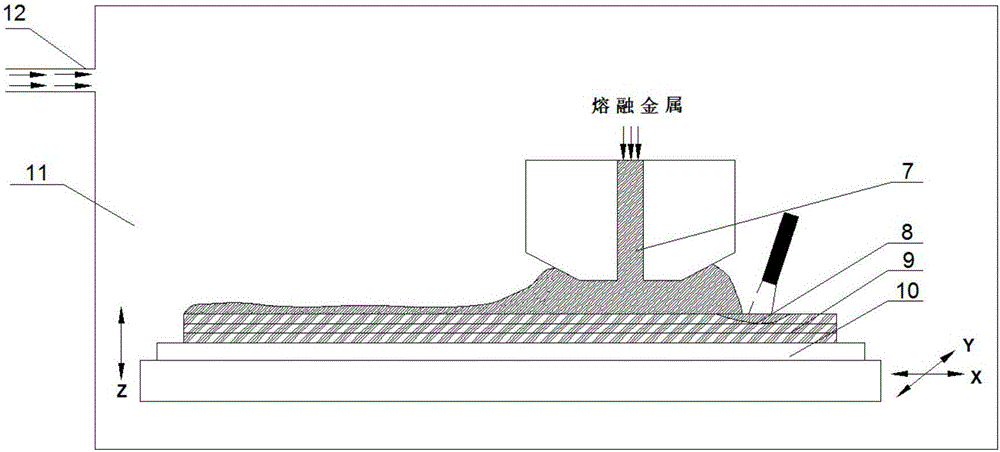

[0033] Such as Figure 1-3 As shown: the invention discloses a metal material melting coating forming device, including a metal melting unit, and also includes a pneumatic driving device, a melting coating head, a laser surface assisted remelting device, a three-dimensional forming platform, and an atmosphere protection device; The device is connected to the metal smelting unit through pipelines; the molten coating head is connected to the lower end of the metal smelting unit, and the three-dimensional forming platform 5 is set under the melting coating head; the laser surface assisted remelting device is set on one of the three-dimensional forming platform 5 Side; the metal smelting unit, the melt coating head, the laser surface assisted remelting device and the three-dimensional forming platform 5 are all arranged in the atmosphere protection device; the atmosphere p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com