A kind of NdFeB magnetic material phosphating solution

A technology of magnetic material and phosphating solution, applied in the field of NdFeB magnetic material surface anti-corrosion, NdFeB magnetic material phosphating solution, can solve the influence of magnetic properties of magnets without analysis, complex phosphating solution formulation, and phosphating process. Complex problems, to achieve the effect of weak acidity, fast speed and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

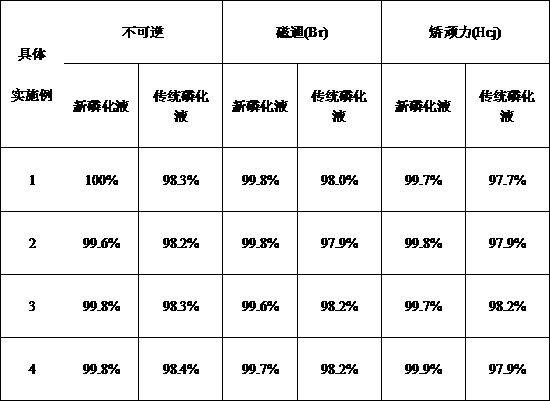

Embodiment 1

[0018] The size of the NdFeB substrate is 13.4mm*3.8mm*14.5mm, the shape is irregular, the single weight is 4.430g magnet, the fluxmeter model is HT700, and the coil is XQ-2.

[0019] A phosphating solution for NdFeB magnetic materials, consisting of the following components: zinc dihydrogen phosphate 100g / L, phosphoric acid 200g / L, tannic acid 15g / L, calcium nitrate 10g / L, ammonium molybdate 20g / L , phytic acid 50g / L, auxiliary film-forming agent 30g / L, and the rest is water. Mix the phosphating solution with pure water at a volume ratio of 3:1 and dilute. The temperature of the phosphating working solution is 70°C. Use NaOH to adjust the acidity of the phosphating solution. The free acid is 5.5 points and the total acid is 13.5 points. After degreasing and derusting, soak in phosphating working solution for 600S, wash and dry to obtain phosphating magnets. The property of this phosphating solution is stable, and the obtained phosphating film is compact and uniform, and no r...

Embodiment 2

[0021] The size of the NdFeB substrate is 13.4mm*3.8mm*14.5mm, the shape is irregular, the single weight is 4.429g magnet, the fluxmeter model is HT700, and the coil is XQ-2.

[0022] A phosphating solution for NdFeB magnetic materials, consisting of the following components: zinc dihydrogen phosphate 100g / L, phosphoric acid 180g / L, tannic acid 13g / L, calcium nitrate 7g / L, ammonium molybdate 14g / L , phytic acid 65g / L, auxiliary film-forming agent 15g / L, and the rest is water. Mix the phosphating solution with pure water at a volume ratio of 4:1 and dilute. The temperature of the phosphating working solution is 50°C. Use NaOH to adjust the acidity of the phosphating solution. The free acid is 4.8 points and the total acid is 12.5 points. After degreasing and derusting, soak in phosphating working solution for 300S, wash and dry to get phosphating magnet. The property of this phosphating solution is stable, and the obtained phosphating film is dense and uniform, and no red rust...

Embodiment 3

[0024] The size of the NdFeB substrate is 13.4mm*3.8mm*14.5mm, the shape is irregular, the single weight is 4.432g magnet, the fluxmeter model is HT700, and the coil is XQ-2.

[0025] A phosphating solution for NdFeB magnetic materials, consisting of the following components: zinc dihydrogen phosphate 60g / L, phosphoric acid 150g / L, tannic acid 10g / L, calcium nitrate 5g / L, ammonium molybdate 10g / L , phytic acid 68g / L, auxiliary film-forming agent 17g / L, and the rest is water. Mix the phosphating solution with pure water at a volume ratio of 6:1 and dilute. The temperature of the phosphating working solution is 50°C. Use NaOH to adjust the acidity of the phosphating solution. The free acid is 4.5 points and the total acid is 12.0 points. After degreasing and derusting, soak in phosphating working solution for 60S, wash and dry to get phosphating magnet. The property of this phosphating solution is stable, and the obtained phosphating film is compact and uniform, and no red rust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com