Automotive brake disc and surface modification method thereof

A technology for automobile braking and surface modification, applied in the direction of brake discs, coatings, mechanical equipment, etc., can solve the problems of high sintering temperature, poor wear resistance, falling off, etc., to achieve broad market prospects, improve fatigue strength, Not easy to peel off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

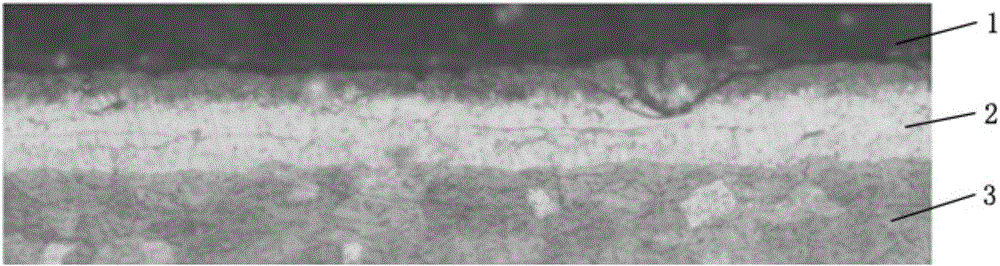

Image

Examples

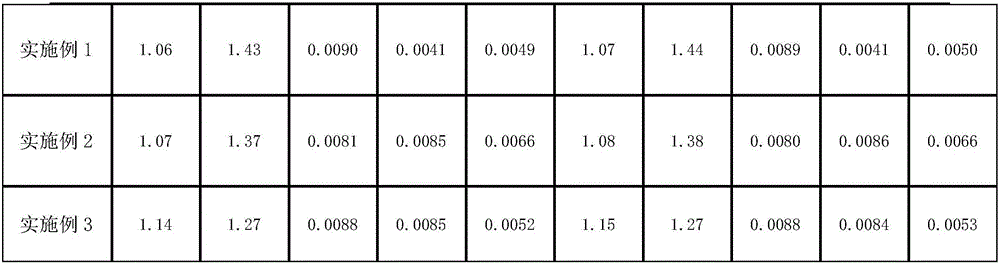

Embodiment 1

[0031] 1. The surface modification method of automobile brake disc is as follows:

[0032] (1) Stress-relief annealing: choose gray cast iron with the brand name of HT250 to make the brake disc, and perform stress-relief treatment on the brake disc to eliminate the stress during the casting process of the brake disc. The stress-relief temperature is about 600°C;

[0033] (2) Primary vacuuming: transfer the brake disc to the oxidation furnace, and vacuumize the furnace pressure. After vacuuming, balance the furnace pressure with nitrogen;

[0034] (3) Pre-oxidation: Introduce purified air into the oxidation furnace, and perform pre-oxidation treatment on the brake disc. The treatment temperature is 400°C and the time is 50 minutes;

[0035] (4) Soft nitriding: transfer the brake disc to the nitriding furnace, and feed NH with a volume ratio of 10:1:9 3 , CO 2 and N 2 The mixed gas is used for nitrocarburizing, the temperature for nitrocarburizing is 590°C, and the furnace pr...

Embodiment 2

[0044] 1. The surface modification method of automobile brake disc is as follows:

[0045] (1) Stress-relief annealing: select the gray cast iron with the grade of HT300 to make the brake disc, and perform stress-relief treatment on the brake disc to eliminate the stress during the casting process of the brake disc. The stress-relief temperature is about 550°C;

[0046] (2) Primary vacuuming: transfer the brake disc to the oxidation furnace, and vacuumize the furnace pressure. After vacuuming, balance the furnace pressure with nitrogen;

[0047] (3) Pre-oxidation: Introduce purified air into the oxidation furnace, and perform pre-oxidation treatment on the brake disc. The treatment temperature is 380°C and the time is 55 minutes;

[0048] (4) Soft nitriding: transfer the brake disc to the nitriding furnace, and feed NH with a volume ratio of 10:1:9 3 , CO 2 and N 2 The mixed gas is used for nitrocarburizing, the temperature for nitrocarburizing is 560°C, and the furnace pre...

Embodiment 3

[0057] 1. The surface modification method of automobile brake disc is as follows:

[0058] (1) Stress-relief annealing: choose gray cast iron with the brand name of HT250 to make the brake disc, and perform stress-relief treatment on the brake disc to eliminate the stress during the casting process of the brake disc. The stress-relief temperature is about 600°C;

[0059] (2) Primary vacuuming: transfer the brake disc to the oxidation furnace, and vacuumize the furnace pressure. After vacuuming, balance the furnace pressure with nitrogen;

[0060] (3) Pre-oxidation: Introduce purified air into the oxidation furnace, and perform pre-oxidation treatment on the brake disc. The treatment temperature is 420°C and the time is 45 minutes;

[0061] (4) Soft nitriding: transfer the brake disc to the nitriding furnace, and feed NH with a volume ratio of 10:1:9 3 , CO 2 and N 2 The mixed gas is used for nitrocarburizing, the temperature for nitrocarburizing is 540°C, and the furnace pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com