Nano-silicon dioxide composite hydrogel for 3D printing and wound repair

A technology of nano-silica and composite hydrogel, applied in biochemical equipment and methods, medical science, microorganisms, etc., can solve the problems of poor optical transparency, high brittleness, and low strength, and achieve high toughness, moderate viscosity and hardness , good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

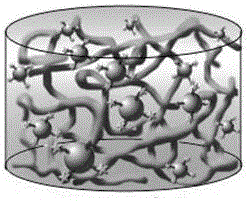

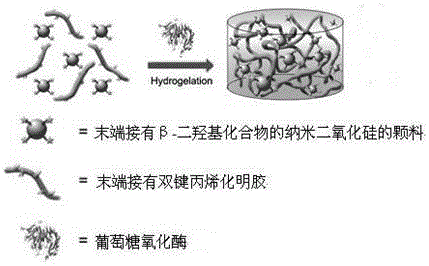

[0032] Such as figure 1 Schematic diagram of nano-silica composite hydrogel structure and figure 2 The preparation diagram of nano-silica composite hydrogel is shown as follows:

[0033] A preparation method of nano-silica composite hydrogel that can be used for 3D printing and wound repair is as follows:

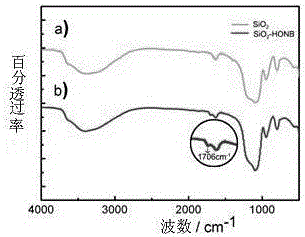

[0034] (1) Synthesis of nanocomposite particles: 2.8mL of ethyl orthosilicate was added dropwise to 147mL of absolute ethanol under stirring, and then 3mL of deionized water and 7.5mL of 28% ammonia water were added, and the mixture was uniformly mixed in a water bath at 40℃. Reflux for 8h. Subsequently, 1 mL of the silane coupling agent KH590 was added to the mixed solution and refluxed in a 40°C water bath for 8 hours. The mixed solution was then centrifuged and washed twice to obtain silica nanoparticles with sulfhydryl groups at the end. The centrifuged nanoparticles Disperse in 15mL Tris-HCl (PH=7.2), add 20mg dithiothreitol (DTT) and stir for 1h, the purpose is to open t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com