White rot fungus biological microsphere and preparation method thereof

A kind of white rot fungus biology and white rot fungus technology, applied in biochemical equipment and methods, methods based on microorganisms, microorganisms, etc., can solve the problems of low reuse rate, harsh growth environment requirements, hindering industrial application, etc., and achieve repeated The effect of high utilization rate, reduction of secondary pollution and avoidance of negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

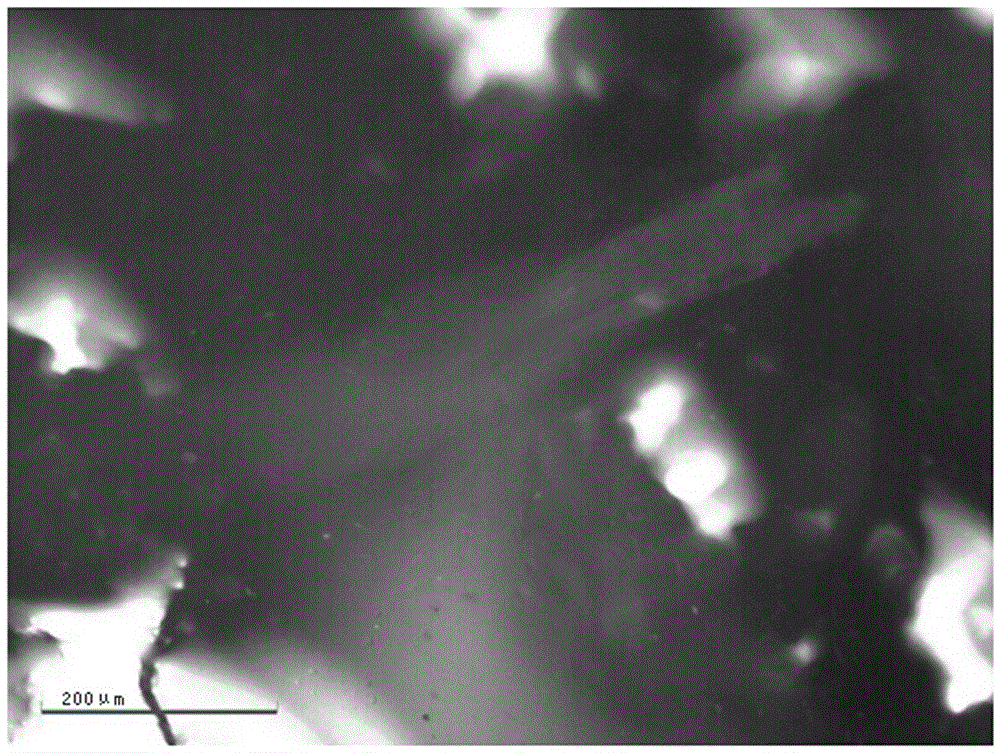

Image

Examples

Embodiment 1

[0035] 1) Preparation of plant straw powder fiber:

[0036] Use a straw crusher to crush the plant straw, and then pass it through a 200-mesh screen to obtain plant straw powder fibers of about 75 μm;

[0037] 2) Preparation of plant straw powder fiber and white rot fungus co-substrate:

[0038] White rot fungus (Phanerochaete chrysosporium) was cultured on liquid medium for one week, filtered, collected white rot fungus mycelium, placed in water, broken up by glass beads and shaken, adding plant straw powder fiber, The mass ratio of mycelium to plant straw powder fiber is 10:1, mix well, culture the mixture in liquid culture medium for 2 days, use fine gauze to filter and remove the culture medium, and obtain the co-substrate of plant straw powder fiber and white rot fungus body; liquid medium components are: glucose 20g / L, KH 2 PO 4 2g / L, MgSO 4 0.25g / L, CaCl 2 0.1g / L, MnSO 4 5mg / L, VB 1 5mg / L, ammonium tartrate 0.2g / L, trace elements 150mL / L;

[0039] 3) Prepar...

Embodiment 2

[0044] 1) Preparation of plant straw powder fiber:

[0045] Use a straw crusher to crush the plant straw, and then pass it through a 200-mesh screen to obtain plant straw powder fibers of about 75 μm;

[0046] 2) Preparation of plant straw powder fiber and white rot fungus co-substrate:

[0047] White rot fungus (trametes versicolor) in solid medium (components: potato extract 200g / L, glucose 20g / L, agar 20g / L, KH 2 PO 4 3g / L, MgSO 4 1.5g / L) for one week, use an inoculation loop to gently scrape the surface of the solid medium to collect white rot fungus spores, put them in water, break up the spores with glass beads and shake them well, add plant straw powder fibers, spores and plant straw powder The fiber mass ratio is 1:10, mix evenly, and put the mixed body in the liquid medium (the components are: glucose 20g / L, KH 2 PO 4 2g / L, MgSO 4 0.25g / L, CaCl 2 0.1g / L, MnSO 4 5mg / L, VB 1 5mg / L, ammonium tartrate 0.2g / L, trace elements 150mL / L) for 2 days, filter the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com