Display method for second phase of austenite heat-resisting steel based on dyeing

A technology of austenitic heat-resistant steel and display method, which is applied in the field of metallographic analysis in steel, can solve the problems of easy confusion of grain boundaries, no good, difficult to distinguish, etc., and achieves low harm to inspectors and the environment, and reusability Strong, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

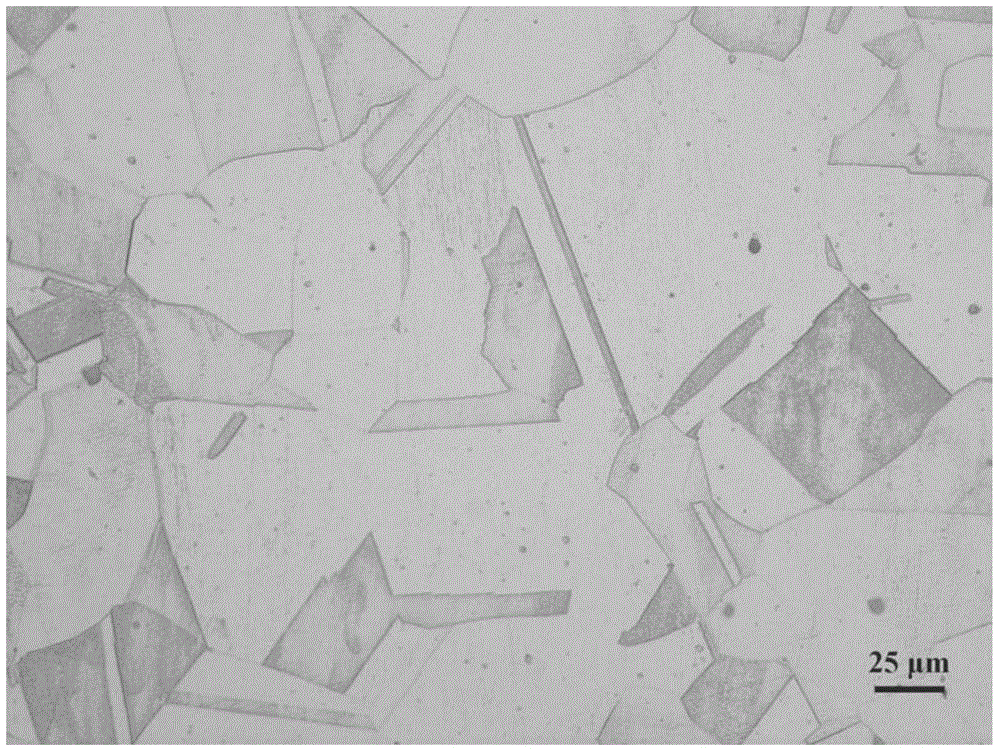

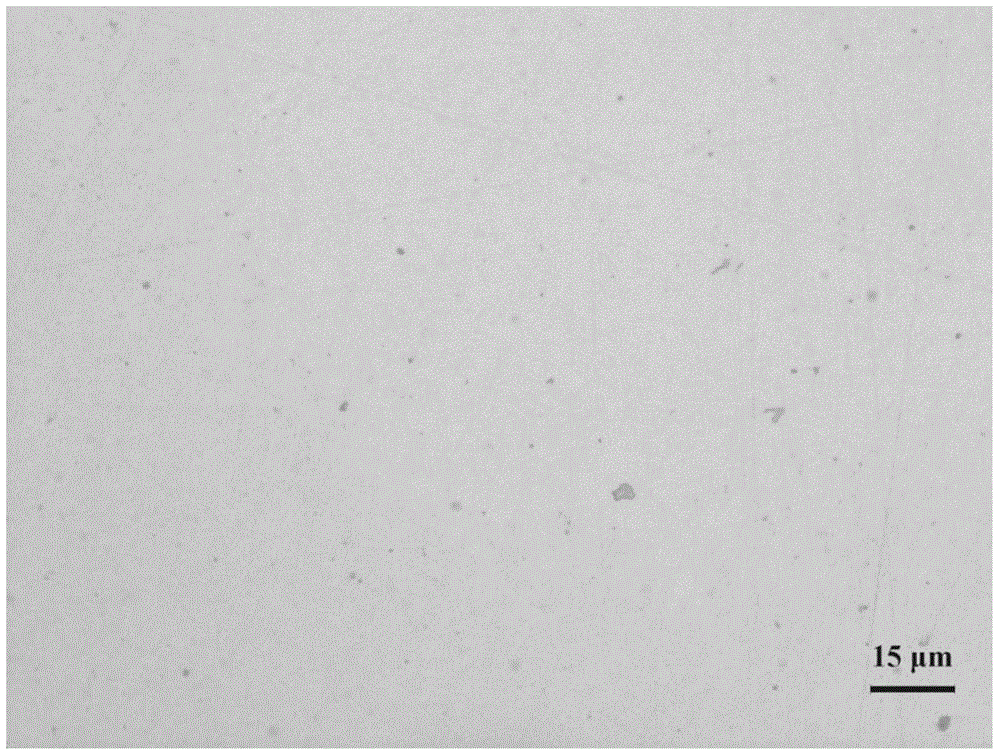

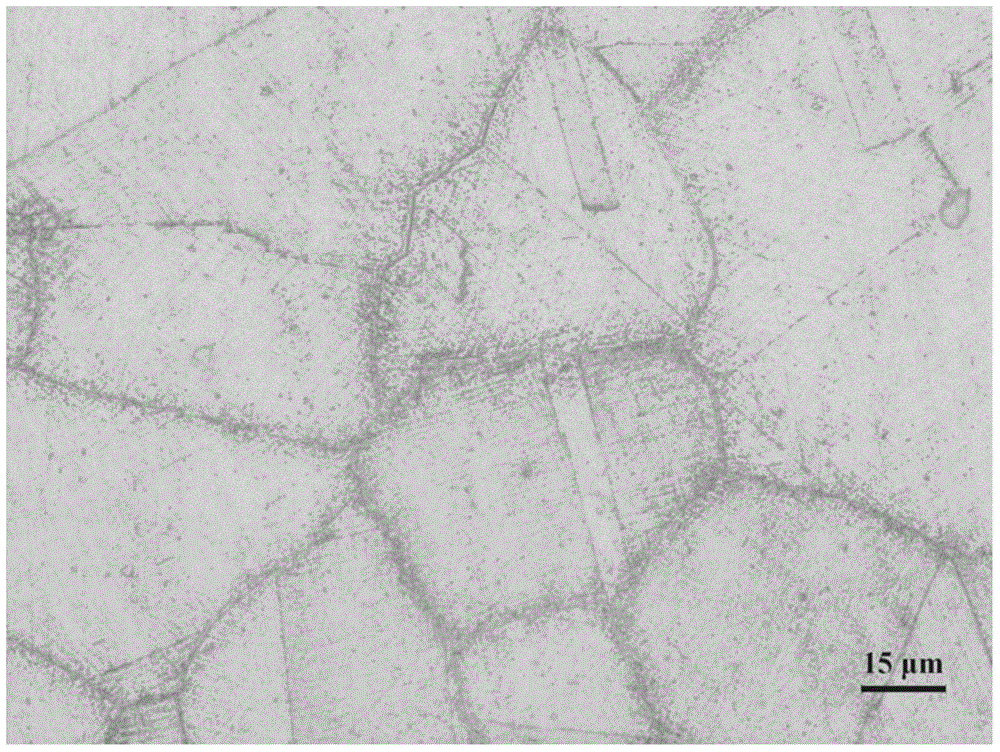

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] A method for displaying the second phase of the dyed austenitic heat-resistant steel based on the present invention comprises the following steps:

[0022] 1) Dye preparation

[0023] Weigh each (3-6) g of sodium hydroxide and potassium permanganate, measure 100ml of water, add the weighed sodium hydroxide and potassium permanganate into 100ml of water, stir with a glass rod until completely dissolved, and prepare alkali Potassium permanganate aqueous dyeing agent;

[0024] 2) Preparation of metallographic specimens of austenitic heat-resistant steel

[0025] The metallographic sample of austenitic heat-resistant steel is prepared by mechanical grinding and polishing. When preparing the metallographic sample of austenitic heat-resistant steel, No. 120, No. 240, No. 480, No. 600, No. 800 and No. 1000 are used in sequence Grind the mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com