Separation method and system for carbonate-rich heavy oil deposits

A heavy oil ore and separation system technology, applied in the fields of reaction, crushing, filtration, sedimentation, and distillation, to achieve the effects of cost reduction, fast reaction speed, and environmental protection treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

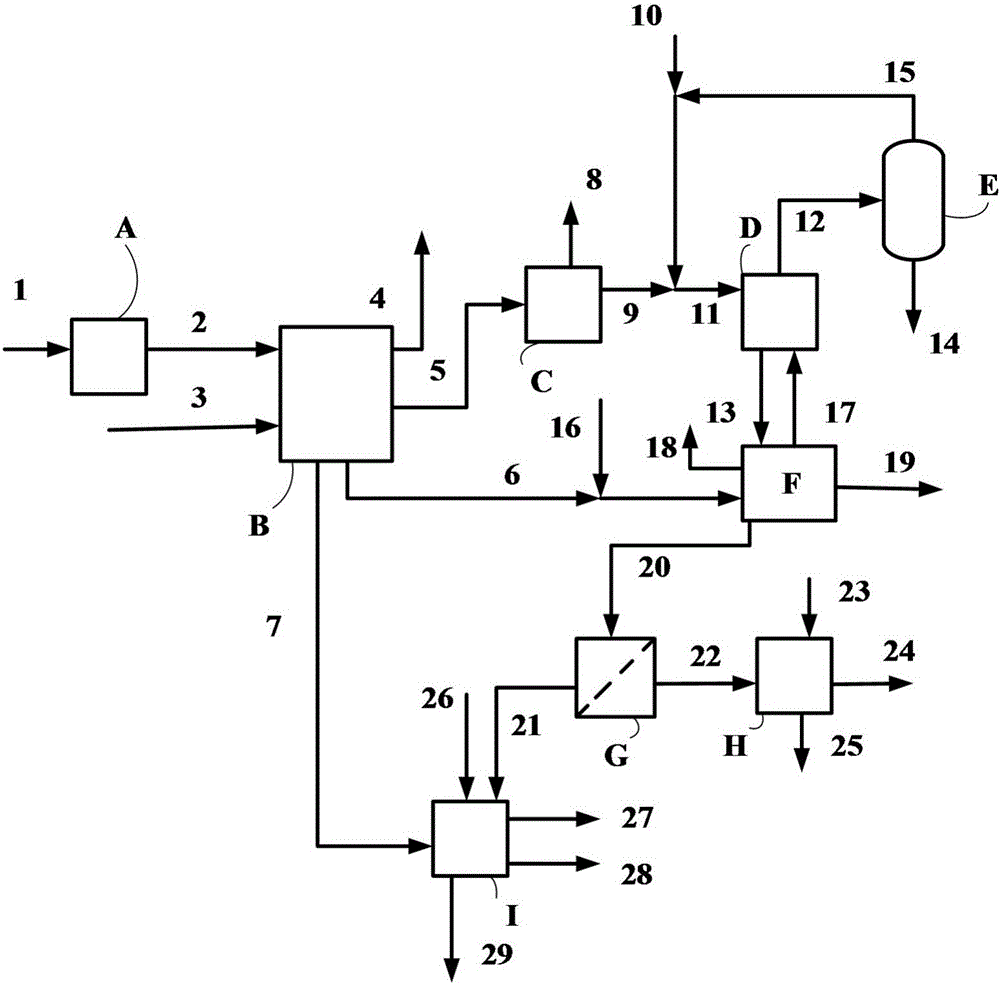

[0053] A high-efficiency separation method and system for carbonate-rich heavy oil deposits, the steps are as follows:

[0054] (1) 15kg of oil sand crushed by crushing device A (carbonate content 42%, maximum particle size 0.5cm) is sent to mixing-reactor B (two-stage parallel connection) and sulfuric acid with a pH of 1 according to the solid-to-liquid ratio of 1: 30 (mass ratio) and mix well at room temperature and react for 1 hour.

[0055] (2) After the degassing operation of C, the obtained asphalt foam is added with 0.5 times the volume of pentane into the solid-liquid separation device D for solid-liquid separation. The water content of the upper oil phase clear liquid obtained after separation is less than 2.5%, and the solid content is less than 1.5%. Separation is carried out in the process, the solvent is recovered, and a deasphaltenized asphalt oil product 14 is obtained at the same time. The recovery rate of asphalt oil is 89.2%, and the asphaltene content is les...

Embodiment 2

[0061] A high-efficiency separation method and system for carbonate-rich heavy oil deposits, the steps are as follows:

[0062] (1) 15kg of oil sand (carbonate content 61%, maximum particle size 5cm) crushed by the crushing device A is sent into the mixing-reactor B (three-stage parallel connection) and phosphoric acid with a concentration of 2 mol / liter according to the solid-liquid ratio 1:3 (mass ratio) fully mix and react at room temperature for 2 hours, and switch operations in turn.

[0063] (2) After the degassing operation of C, the obtained asphalt foam is added with 5 times the volume of pentane for solid-liquid separation. The water content in the upper oil phase clear liquid obtained from the separation is less than 1.5%, and the solid content is less than 0.5%. It enters E for separation and recovery of solvent , while obtaining deasphaltenized asphalt oil product 14, the recovery rate of asphalt oil is 85.8%, and the asphaltene content is less than 3.5%.

[0064...

Embodiment 3

[0069] A high-efficiency separation method and system for carbonate-rich heavy oil deposits, the steps are as follows:

[0070] (1) 15kg of oil sludge crushed by crushing device A (carbonate content 56%, maximum particle size 1.5cm) is sent to mixing-reactor B with oxalic acid with a concentration of 3 mol / liter according to the solid-liquid ratio of 1:3 ( Mass ratio) fully mixed and reacted at normal temperature for 120min, after mixing, enter the degassing device to degas the foam;

[0071](2) After the obtained asphalt foam is degassed by C, 5 times the volume of heptane is added for solid-liquid separation. The upper oil phase clear liquid obtained by solid-liquid separation device D has a moisture content of less than 1.5%, and a solid content of less than 1.5%, and enters the solvent The recovery device is used for solvent recovery and at the same time to obtain asphalt oil products. The recovery rate of asphalt oil is 88.7%, and the asphaltene content is less than 5%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com