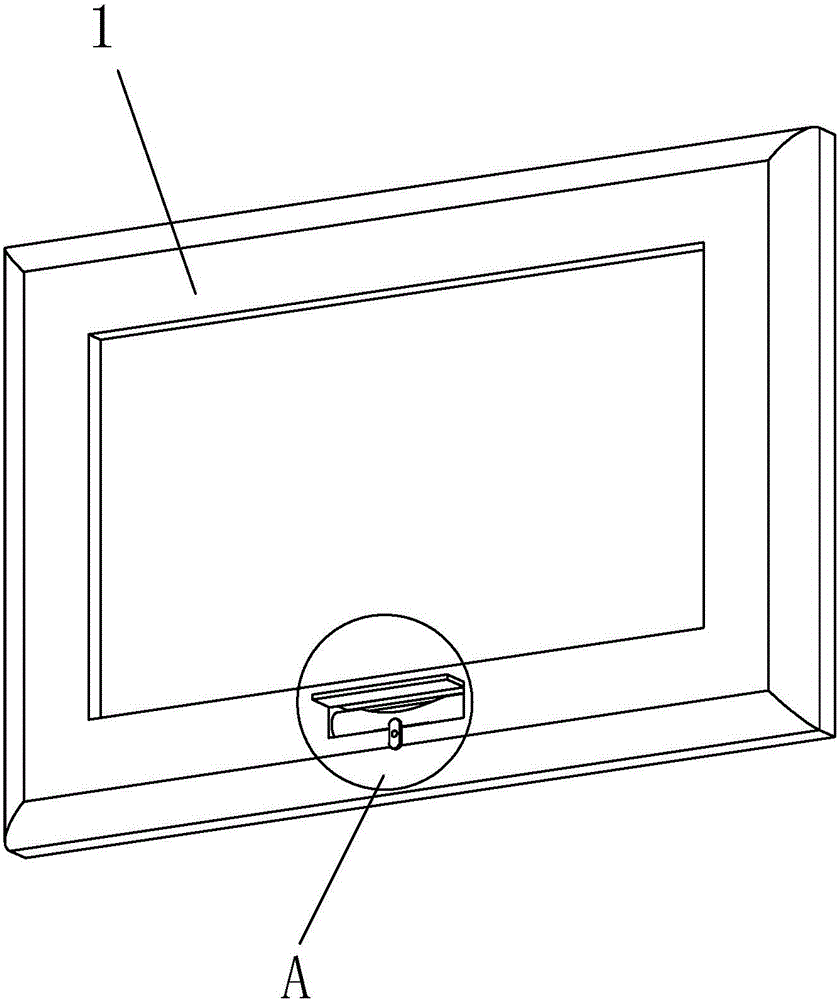

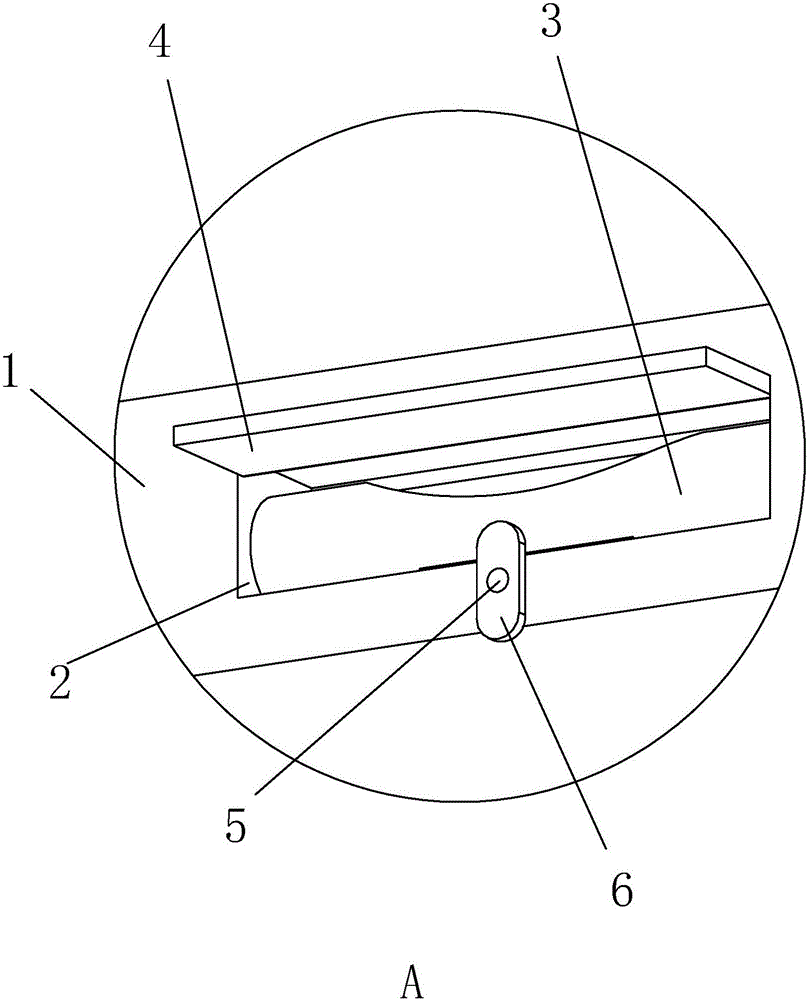

Photo frame and water-borne wood paint used on photo frame

A water-based wood paint and photo frame technology, which is applied in the field of home decorations, can solve problems such as the decrease in the accuracy of the bubble level, the difficulty in replacing the bubble level in time, and the inability to place the photo frame in a horizontal position. It achieves low surface tension, good chemical stability, Ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

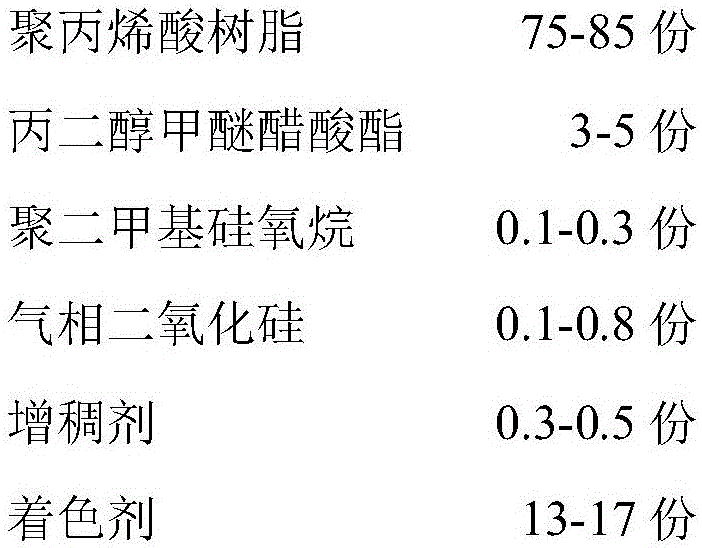

[0046] Step1: Add 75 parts of polyacrylic resin and 15 parts of deionized water according to parts by weight, start the machine at 250 rpm, and stir evenly;

[0047] Step2: In parts by weight, add 3 parts of propylene glycol methyl ether acetate and 0.1 part of polydimethylsiloxane, and disperse at a speed of 500 rpm for 10 minutes;

[0048] Step3: According to parts by weight, add 0.5 part of fumed silica and 0.5 part of thickener, and disperse for 10 minutes at a speed of 400 rpm, wherein according to parts by weight, the thickener is sodium hydroxymethylcellulose: polyvinyl alcohol : diatomaceous earth = 1:3:5;

[0049] Step4: According to parts by weight, add 15 parts of colorant and 3.5 parts of talcum powder, and disperse for 5 minutes at a speed of 600 rpm, wherein according to parts by weight, the colorant is titanium dioxide: zinc oxide=1:2;

[0050] Step5: In parts by weight, finally add 0.5 parts of phenyl o-hydroxybenzoate and 0.9 parts of macroporous adsorption r...

Embodiment 2

[0052] Step1: Add 85 parts of polyacrylic resin and 14 parts of deionized water according to parts by weight, start the machine at 300 rpm, and stir evenly;

[0053] Step2: Add 5 parts of propylene glycol methyl ether acetate and 0.3 parts of polydimethylsiloxane according to parts by weight, and disperse at 800 rpm for 10 minutes;

[0054] Step3: According to parts by weight, add 0.8 parts of fumed silicon dioxide and 0.3 parts of thickener, and disperse for 10 minutes at a speed of 600 rpm, wherein according to parts by weight, the thickener is sodium hydroxymethylcellulose: polyvinyl alcohol : diatomaceous earth = 1:7:5;

[0055]Step4: According to parts by weight, add 13 parts of colorant and 3 parts of calcium carbonate, and disperse for 5 minutes at a speed of 800 rpm, wherein according to parts by weight, the colorant is titanium dioxide: zinc oxide=1:3;

[0056] Step5: In parts by weight, finally add 0.4 parts of 2,4-dihydroxybenzophenone and 0.5 parts of macroporous ...

Embodiment 3

[0058] Step1: According to parts by weight, put in 80 parts of polyacrylic resin and 13 parts of deionized water, start the machine at 270 rpm, and stir evenly; Step2: According to parts by weight, add 4 parts of propylene glycol methyl ether acetate and polydimethylsiloxane 0.2 parts of alkane, dispersed at 600 rpm for 10 minutes;

[0059] Step3: According to parts by weight, add 0.1 part of fumed silicon dioxide and 0.4 part of thickener, and disperse at a speed of 500 rpm for 10 minutes, wherein according to parts by weight, the thickener is sodium hydroxymethylcellulose: polyvinyl alcohol : diatomaceous earth = 1:3:8;

[0060] Step4: According to parts by weight, add 14 parts of colorant and 2.5 parts of barium sulfate, and disperse for 5 minutes at a speed of 700 rpm, wherein according to parts by weight, the colorant is titanium dioxide: zinc oxide=1:4;

[0061] Step5: According to parts by weight, finally add 0.6 parts of 2-(2'-hydroxyl-5'-methylphenyl)benzotriazole an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com