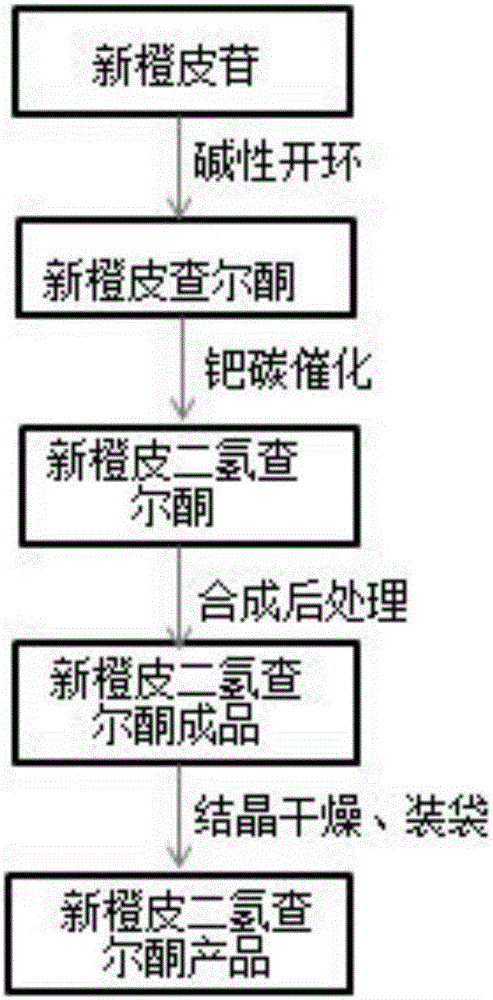

Preparation method of neohesperidin dihydrochalcone

A technology of neohesperidin dihydrochalcone and neohesperidin is applied in the field of preparation of neohesperidin dihydrochalcone, and can solve the problem of low purity and yield of neohesperidin dihydrochalcone , higher equipment and technical requirements, increased operation steps, etc., to achieve the effect of easy reuse, lower production costs, and fewer operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for neohesperidin dihydrochalcone, comprising the following steps:

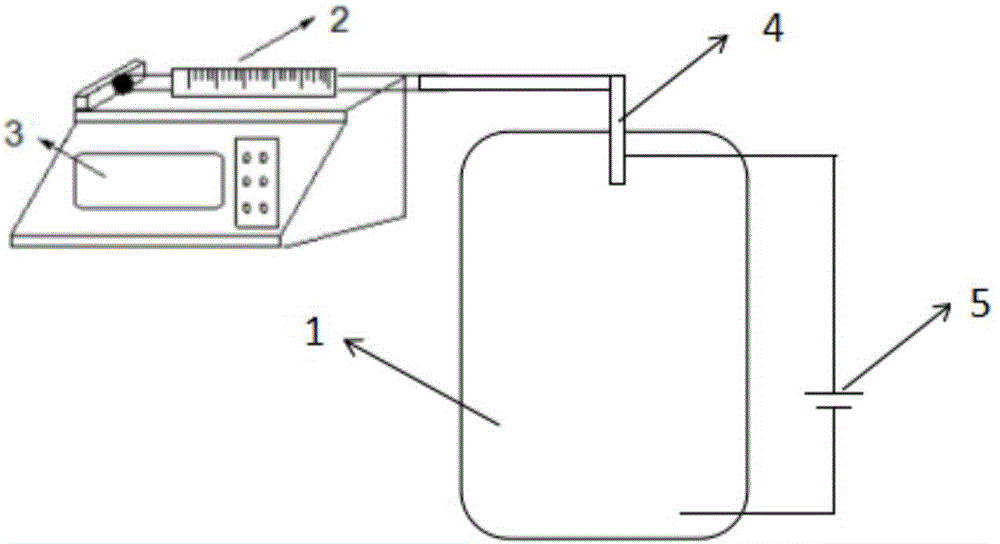

[0029] Step 1, adding 1kg neohesperidin and 15kg mass fraction of 6% sodium hydroxide solution into the reactor, stirring and dissolving, then adding 0.05kg catalyst palladium carbon, sealing the reactor, replacing the air in the reactor with nitrogen, Then feed hydrogen to replace nitrogen at normal temperature, stir and react under normal pressure for 10 hours, after the reaction is completed, use nitrogen to replace hydrogen in the reactor, then stop the reaction, and extract the reaction solution;

[0030] Step 2, adjust the pH of the reaction solution to 5, crystallize at room temperature for 10 hours, and filter to obtain crystal A; the obtained filtrate is adsorbed with macroporous resin D101, and after adsorption, it is eluted with purified water to remove the salt in the filtrate; then use 15 The volume fraction of twice the column volume is eluted with 10% ethanol, and th...

Embodiment 2

[0032] A preparation method for neohesperidin dihydrochalcone, comprising the following steps:

[0033] Step 1, adding 1kg neohesperidin and 20kg mass fraction of 15% sodium hydroxide solution into the reactor, stirring and dissolving, then adding 0.06kg catalyst palladium carbon, sealing the reactor, replacing the air in the reactor with nitrogen, Then feed hydrogen to replace nitrogen at normal temperature, stir and react under normal pressure for 15 hours, after the reaction is completed, use nitrogen to replace hydrogen in the reactor, then stop the reaction, and extract the reaction solution;

[0034]Step 2. Adjust the pH of the reaction solution to 6, crystallize at room temperature for 15 hours, and filter to obtain crystal A; the obtained filtrate is adsorbed with macroporous resin D101, and after adsorption, it is eluted with purified water to remove the salt in the filtrate; The volume fraction of twice the column volume is eluted with 25% ethanol, and then eluted wi...

Embodiment 3

[0036] A preparation method for neohesperidin dihydrochalcone, comprising the following steps:

[0037] Step 1, adding 1kg neohesperidin and 18kg mass fraction of 10% sodium hydroxide solution into the reactor, stirring and dissolving, then adding 0.0625kg catalyst palladium carbon, sealing the reactor, replacing the air in the reactor with nitrogen, Then feed hydrogen to replace nitrogen at normal temperature, stir and react under normal pressure for 12 hours, after the reaction is completed, use nitrogen to replace hydrogen in the reactor, then stop the reaction, and extract the reaction solution;

[0038] Step 2. Adjust the pH of the reaction solution to 6, crystallize at room temperature for 12 hours, and filter to obtain crystal A; the obtained filtrate is adsorbed with macroporous resin D101, and after adsorption, it is eluted with purified water to remove the salt in the filtrate; then, use 18 The volume fraction of twice the column volume is eluted with 20% ethanol, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com