Preparation method of pyrophosphate piperazine

A technology for piperazine pyrophosphate and piperazine, which is applied in the field of chemistry, can solve the problems of slow salt formation between phosphoric acid and piperazine, increase production cost, increase transportation cost and other problems, and achieves low price, reduced raw material cost and stable properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

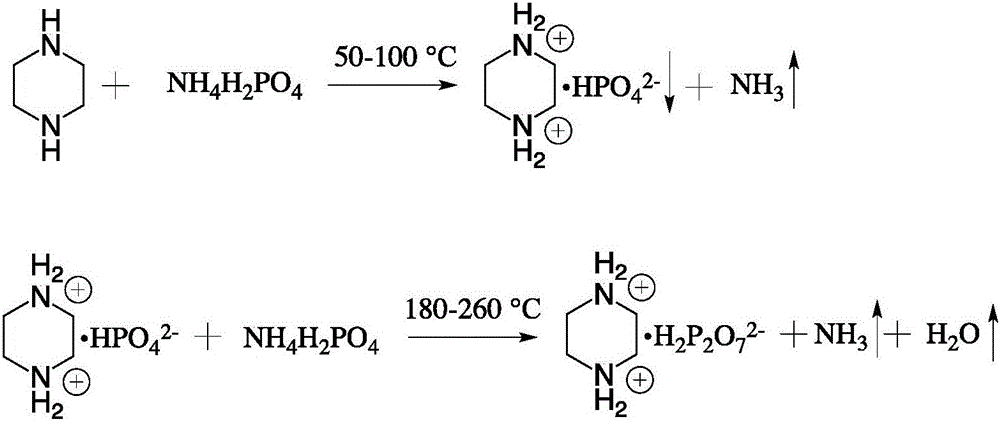

[0024] In a 10L glass reaction kettle equipped with a stirrer, a thermometer and an exhaust pipe, add 1.15kg of ammonium dihydrogen phosphate and 1000mL of distilled water, raise the temperature to 85-90°C, add 430g of anhydrous piperazine solids in batches, and keep the temperature for 3 hours. A white turbid liquid intermediate was obtained; 6 L of liquid paraffin was added, stirred and reacted at 210° C. for 1 hour, filtered, the precipitate was washed with petroleum ether, and dried to obtain a white powder of piperazine pyrophosphate.

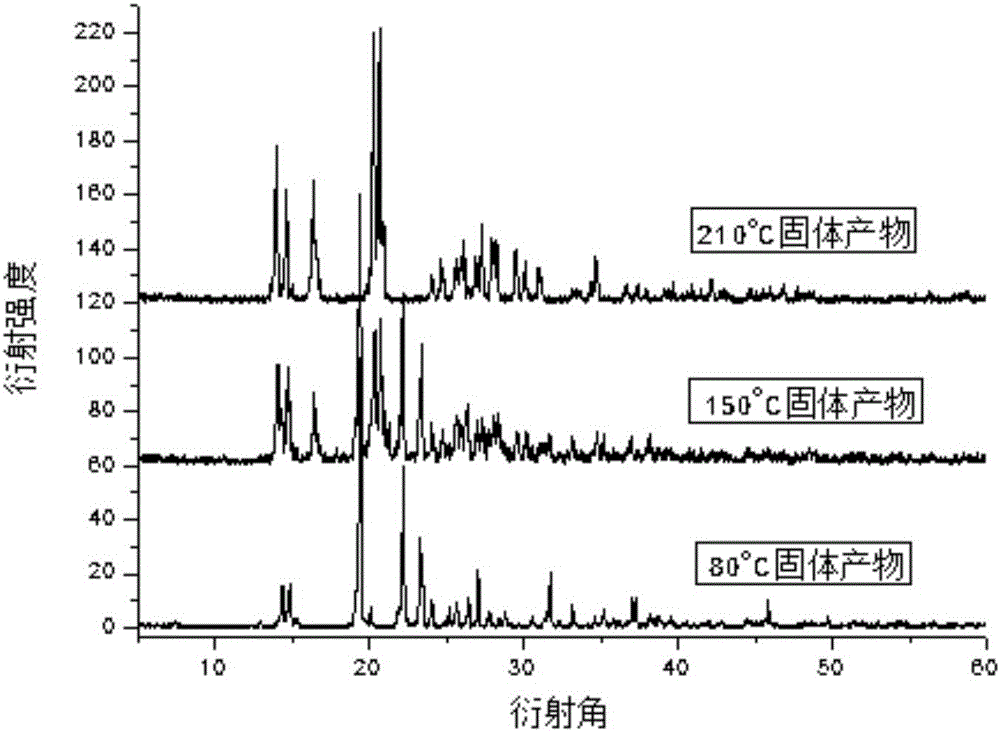

[0025] According to the literature, the solid insoluble matter obtained at 80°C is mainly piperazine hydrogen phosphate, the solid insoluble matter obtained at 150°C is mainly a mixture of piperazine hydrogen phosphate and piperazine pyrophosphate, and at 210°C is pyrophosphate piperazine phosphate.

Embodiment 2

[0027] In a 10L vacuum kneader, add 2.35kg of ammonium dihydrogen phosphate and 1.5L of distilled water, raise the temperature to 85-90°C, add 860g of anhydrous piperazine solid in batches, keep the reaction for 1 hour, and remove water under vacuum for 1 hour. Under vacuum and reduced pressure, the reaction temperature was gradually increased to 230° C., and the kneading reaction was continued for 40 minutes to obtain a white powder of piperazine pyrophosphate.

[0028] Embodiment 2 technology and comparative example technology cost accounting table (cost saving 14.4%)

[0029]

Embodiment 3

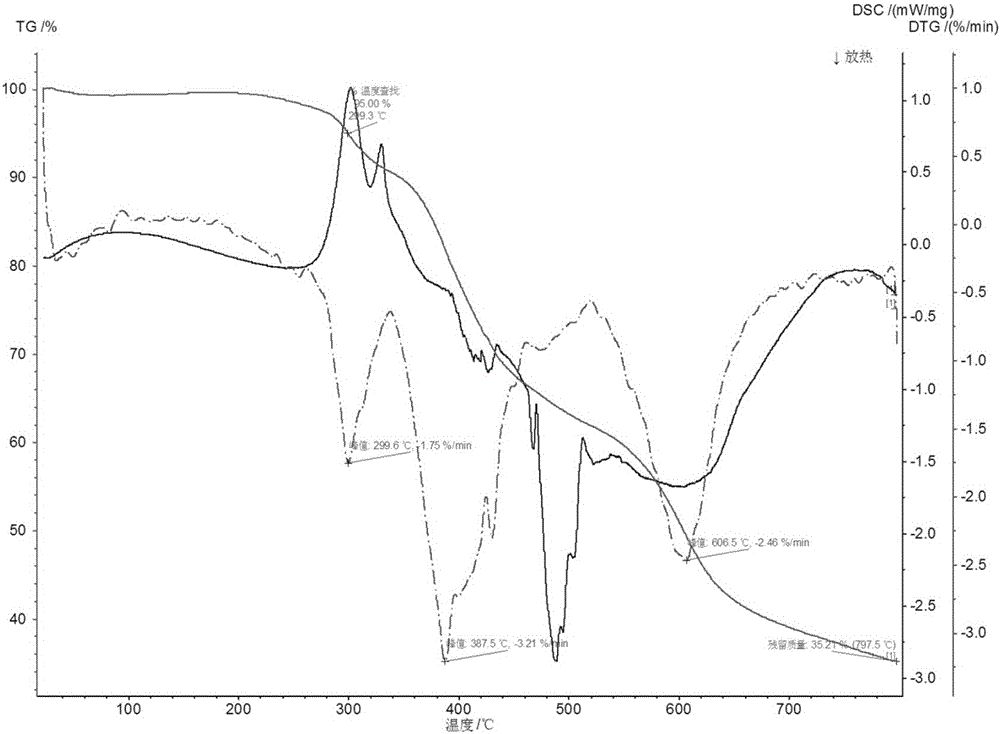

[0031] Add 1.15kg ammonium dihydrogen phosphate and 1.1L distilled water to a 10L glass reactor equipped with a stirrer, a thermometer and an exhaust pipe, raise the temperature to 85-90°C, add 430g of anhydrous piperazine solids in batches, and keep the temperature for 3 hours. , to obtain a white turbid liquid intermediate; add 7L of high-temperature silicone oil, stir and react at 220°C for 1 hour, filter, wash the precipitate with petroleum ether, and dry to obtain a white powder of piperazine pyrophosphate. From figure 2 It can be seen that the product has high thermal stability, and the 5% decomposition temperature is 299°C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com