Radar and infrared compatible stealth material based double-layer frequency selective surface and preparation method of radar and infrared compatible stealth material

A frequency selective surface, stealth material technology, applied in the field of radar absorbing materials, to meet the needs of light weight, reduce weight, and excellent anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

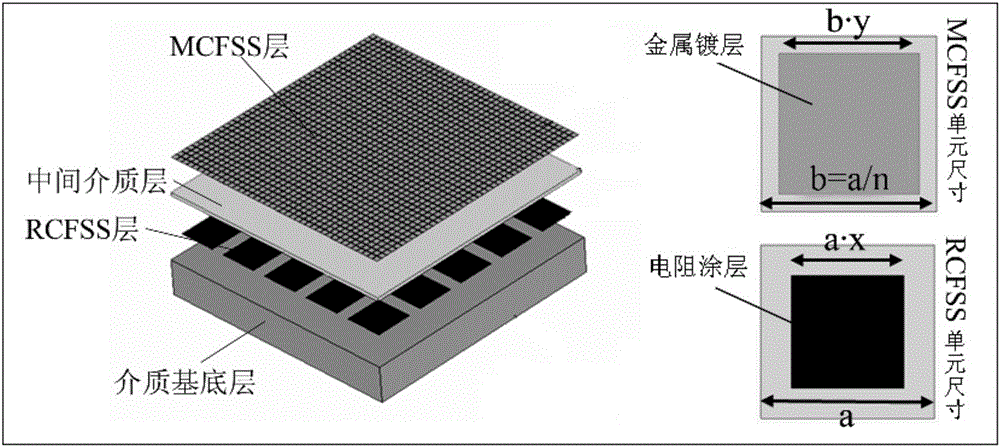

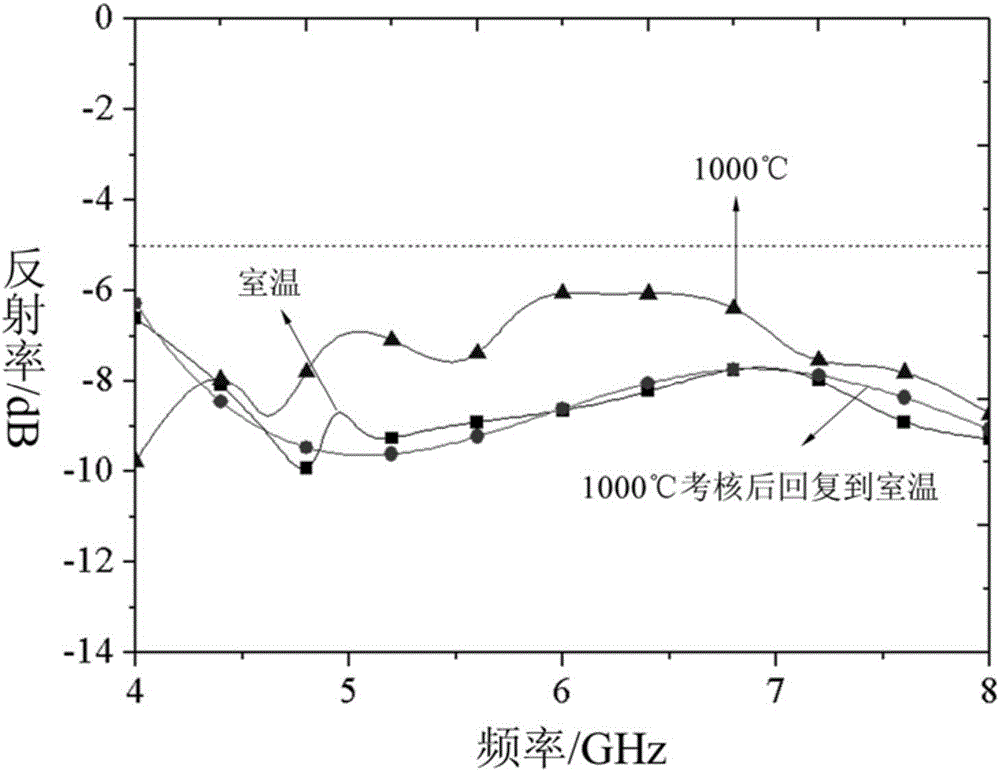

[0049] A radar and infrared compatible stealth material based on a double-layer frequency selective surface of the present invention, such as figure 1 As shown, it includes a dielectric base layer, a resistive capacitive frequency selective surface layer (RCFSS layer), an intermediate dielectric layer, and a metal type capacitive frequency selective surface layer (MCFSS layer) from the inside to the outside; wherein, the material of the dielectric base layer The mullite fiber reinforced mullite-based composite material is used, and the thickness of the dielectric base layer is 2.65mm; the resistive capacitive frequency selective surface layer (RCFSS layer) is composed of a periodic pattern of high-temperature resistant resistance coating (ruthenium dioxide system Glass-based resistance coating), the thickness of the high temperature resistant coating is 0.02mm, the periodic pattern is a square patch pattern distributed in a matrix, the side length of the matrix unit where the s...

Embodiment 2

[0062] A radar and infrared compatible stealth material based on a double-layer frequency selective surface of the present invention, such as figure 1 As shown, it includes a dielectric base layer, a resistive capacitive frequency selective surface layer (RCFSS layer), an intermediate dielectric layer, and a metal type capacitive frequency selective surface layer (MCFSS layer) from the inside to the outside; wherein, the material of the dielectric base layer Alumina fiber-reinforced alumina-based composite materials are used, and the thickness of the dielectric base layer is 1.62mm; the resistance-type capacitive frequency-selective surface layer (RCFSS layer) is composed of a periodic pattern of high-temperature-resistant resistance coating (ruthenium dioxide-based glass substrate) resistance coating), the thickness of the high-temperature-resistant coating is 0.02mm, and the periodic pattern is a square patch pattern distributed in a matrix. The side length of the matrix unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com