Method for easily and conveniently preparing Mn3O4 nanopowder and product of method

A nano powder, a simple technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of pure product, low price and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

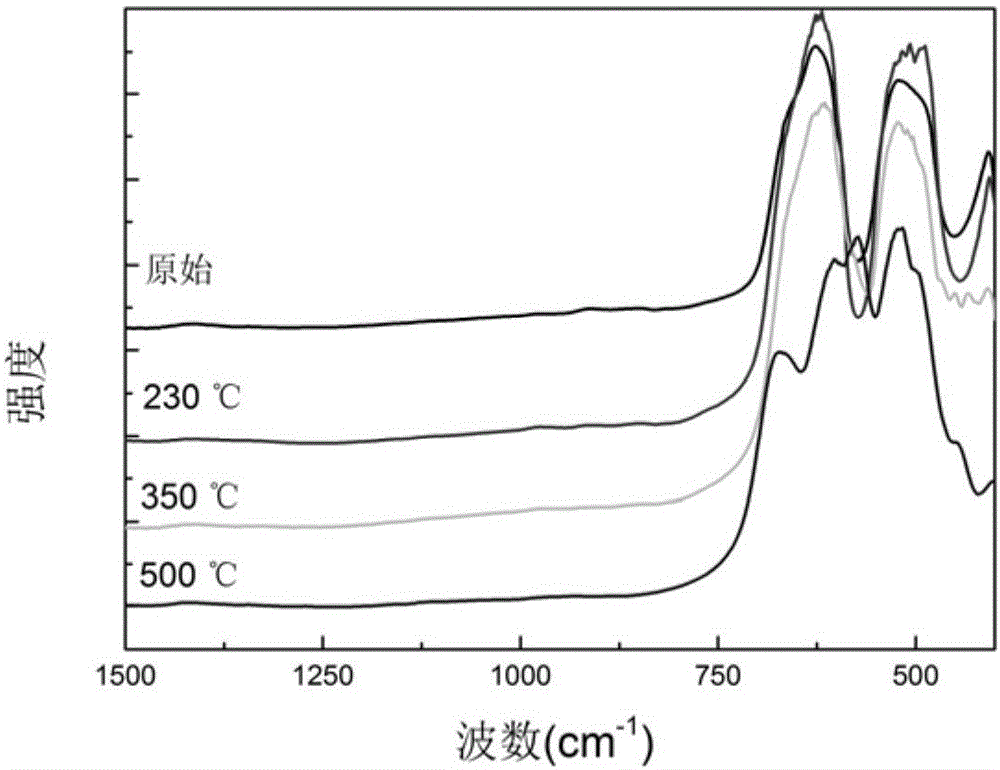

Method used

Image

Examples

Embodiment 1

[0032] Weigh 0.05mol Mn(Ac) 2 4H 2 Add 300ml of deionized water to O crystals, dissolve in a three-necked flask, heat and stir in a water bath, and the water temperature is 80°C. Measure 0.1 mol of hydrogen peroxide and add 100 ml of deionized water to dilute, then measure 0.1 mol of ammonia water and add 100 ml of deionized water to dilute, and mix the two to obtain a mixed solution. After the crystals in the flask are completely dissolved and the temperature of the water bath is stable, slowly add the mixed solution of hydrogen peroxide and ammonia water dropwise, keep stirring rapidly, seal the flask after the dropwise addition, and continue the reaction for 2 to 3 hours. After the reaction, the flask was removed, the reactant was transferred to a beaker, sealed and ultrasonically treated for 30 min, and then left to stand in a fume hood. Pour off the supernatant repeatedly, add deionized water and let it stand until the pH of the supernatant is close to 7. If the standst...

Embodiment 2

[0037] Weigh 0.05mol Mn(Ac) 2 4H 2 Add 300ml of deionized water to O crystals, dissolve in a three-necked flask, heat and stir in a water bath, and the water temperature is 80°C. Measure 0.1 mol each of hydrogen peroxide and ammonia water, add 100 ml of deionized water to dilute, and then mix the two to obtain a mixed solution. After the crystals in the flask are completely dissolved and the temperature of the water bath is stable, slowly add the mixed solution of hydrogen peroxide and ammonia water dropwise, keep stirring rapidly, seal the flask after the dropwise addition, and continue the reaction for 2 to 3 hours. After the reaction, the flask was removed, and the reactant was transferred to a beaker for ultrasonication for 45 min, sealed and placed in a fume hood to stand still. Pour off the supernatant repeatedly, add deionized water and let it stand until the pH of the supernatant is close to 7, centrifuge the last reactant, pour off the supernatant, transfer the sedi...

Embodiment 3

[0040] Weigh 0.05mol Mn(Ac) 2 4H 2 Add 300ml of deionized water to O crystals, dissolve in a three-necked flask, heat and stir in a water bath, and the water temperature is 75°C. Measure 0.15 mol of hydrogen peroxide and 0.1 mol of ammonia water, respectively add 100 ml of deionized water to dilute, and then mix the two to obtain a mixed solution. After the crystals in the flask are completely dissolved and the temperature of the water bath is stable, slowly add the mixed solution of hydrogen peroxide and ammonia water dropwise, keep stirring rapidly, seal the flask after the dropwise addition, and continue the reaction for 2 to 3 hours. After the reaction, the flask was removed, and the reactant was transferred to a beaker for ultrasonication for 60 min, sealed and placed in a fume hood to stand still. Filter the product, wash it repeatedly with deionized water for 4 to 5 times until the pH of the washed deionized water is close to 7, transfer the precipitate on the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com