Method for preparing manganese dioxide nanosheet in low-temperature hydrothermal mode

A manganese dioxide and hydrothermal technology, applied in manganese oxide/manganese hydroxide and other directions, can solve problems such as unfavorable production of manganese dioxide, and achieve strong practicability, increased interlayer spacing, good electrical conductivity and ultra-high performance. Effects of Capacitive Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of manganese dioxide nanosheets

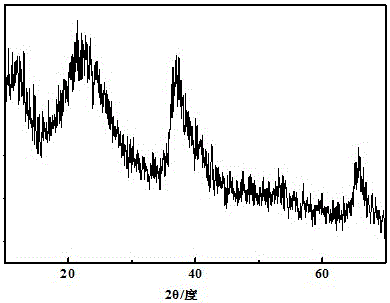

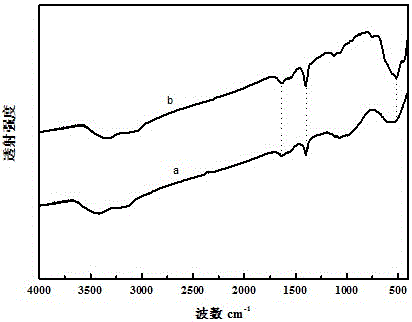

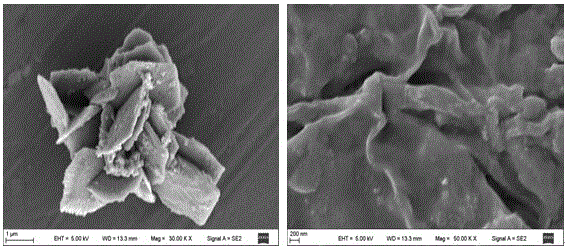

[0036] At room temperature, dissolve 32mg of potassium permanganate in 40ml of water to form a uniform potassium permanganate solution, then add 2.7mg of surfactant SDS and stir evenly; then slowly add 2ml of ethylene glycol dropwise and stir evenly; then heat up to 80°C , stirred and reacted for 120 minutes; the reaction product was washed and dried to obtain manganese dioxide nanosheets. For its structural characterization, see figure 1 , 2 , 3.

[0037] 2. Manganese dioxide nanosheet electrode preparation

[0038] Manganese dioxide nanosheets, acetylene black, and polytetrafluoroethylene were uniformly mixed at a mass ratio of 75%:15%:10%, respectively, and then coated on 1×1cm 2 On the nickel foam current collector, vacuum dry at 60°C for 12h. The content of manganese dioxide nanosheets on each working electrode is about 2 mg. After the mixture is evenly spread, the geometric surface area of the working electro...

Embodiment 2

[0043] 1. Preparation of manganese dioxide nanosheets: no surfactant SDS was added, and the others were the same as in the examples.

[0044] 2. Manganese dioxide nanosheet electrode preparation: the same as in Example 1.

[0045] 3. Electrochemical properties of manganese dioxide: the test conditions and test methods are the same as in Example 1.

[0046] Test results: at a current density of 1A·g -1 , the specific capacitance reached 160F·g -1 , with a current density of 5A g -1 , the specific capacitance can still reach 91F·g -1 , The capacitance retention rate is 56.9%.

Embodiment 3

[0048] At room temperature, dissolve 32mg of potassium permanganate in 40ml of water to form a uniform potassium permanganate solution, then add 2.7mg of surfactant SDS; slowly add 2ml of ethylene glycol dropwise and stir well; then transfer to a 40°C water bath , stirred and reacted for 120 minutes; the reaction product was washed and dried to obtain manganese dioxide nanosheets.

[0049] 2. Manganese dioxide nanosheet electrode preparation: the same as in Example 1.

[0050] 3. Electrochemical properties of manganese dioxide: the test conditions and test methods are the same as in Example 1.

[0051] Test results: at a current density of 1A·g -1 , the specific capacitance reached 164F·g -1 , with a current density of 5A g -1 , the specific capacitance can still reach 125F·g -1 , The capacitance retention rate is 76.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com