Method for preparing anhydrous aluminum chloride by microwave chlorination of fly ash

An anhydrous aluminum chloride, fly ash technology, applied in aluminum chloride, chemical instruments and methods, aluminum halide and other directions, can solve the problems of high production cost, high energy consumption, complicated operation, etc. The effect of high thermal efficiency and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

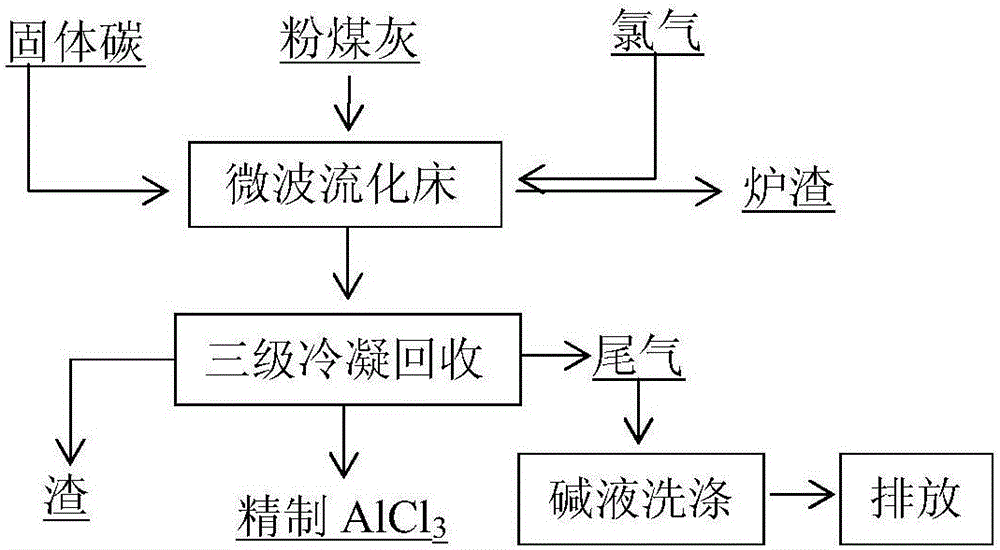

[0033]A method for preparing anhydrous aluminum chloride by microwave chlorination of fly ash, comprising the following steps:

[0034] Step 1, high aluminum fly ash microwave heating chlorination decomposition:

[0035] Add activated carbon to the high-alumina fly ash containing 25% alumina, mix evenly, pass in chlorine gas, the pressure is normal pressure, use a microwave fluidized bed with a microwave frequency of 2.5 GHz to heat for 10 minutes, reach 800 ° C, keep the temperature for 20 minutes, Fully decompose the high-alumina fly ash to obtain a variety of chlorinated mixed gases containing aluminum chloride; wherein, according to the mass ratio, high-alumina fly ash: activated carbon = 1: 2, high-alumina fly ash: chlorine = 1: 4;

[0036] Step 2, separation and purification:

[0037] A variety of chlorinated mixed gases containing aluminum chloride remove impurities through a three-stage condensation recovery device to obtain anhydrous aluminum chloride products with ...

Embodiment 2

[0040] A method for preparing anhydrous aluminum chloride by microwave chlorination of fly ash, comprising the following steps:

[0041] Step 1, high aluminum fly ash microwave heating chlorination decomposition:

[0042] Add petroleum coke to the high-alumina fly ash containing 30% alumina, mix evenly, pass in chlorine gas, the pressure is normal pressure, use a microwave fluidized bed with a microwave frequency of 2.5GHz to heat for 5 minutes, reach 700°C, and keep the temperature constant for 30 minutes , the high-alumina fly ash is fully decomposed to obtain a variety of chlorinated mixed gases containing aluminum chloride; wherein, by mass ratio, high-alumina fly ash: petroleum coke = 1: 1.5, high-alumina fly ash: chlorine gas = 1:3;

[0043] Step 2, separation and purification:

[0044] A variety of chlorinated mixed gases containing aluminum chloride remove impurities through a three-stage condensation recovery device to obtain anhydrous aluminum chloride products wit...

Embodiment 3

[0047] A method for preparing anhydrous aluminum chloride by microwave chlorination of fly ash, comprising the following steps:

[0048] Step 1, high aluminum fly ash microwave heating chlorination decomposition:

[0049] Add charcoal to the high-alumina fly ash containing 25% alumina, mix evenly, pass in chlorine gas, the pressure is normal pressure, use a microwave fluidized bed with a microwave frequency of 2.3GHz to heat for 30min, reach 900°C, and keep the temperature constant for 10min , the high-alumina fly ash is fully decomposed to obtain a variety of chlorinated mixed gases containing aluminum chloride; wherein, by mass ratio, high-alumina fly ash: charcoal = 1: 3, high-alumina fly ash: chlorine = 1:5;

[0050] Step 2, separation and purification:

[0051] A variety of chlorinated mixed gases containing aluminum chloride remove impurities through a three-stage condensation recovery device to obtain anhydrous aluminum chloride products with a purity greater than 99%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com