Machine used for punching ceramic dielectric chip of high-pressure ceramic capacitor and capable of preventing die damage

A high-pressure ceramic and porcelain medium technology, applied in ceramic molding machines, molding indenters, manufacturing tools, etc., can solve problems such as damage, mold cracking, poor reliability, etc., to achieve high reliability and avoid mold air pressure effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

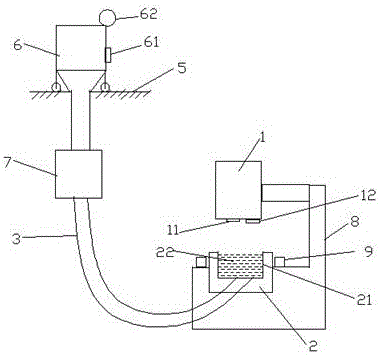

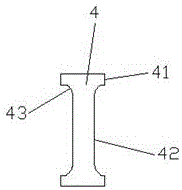

[0027] Such as figure 1 and figure 2 As shown, there are upper punch 1, height sensor 11, pressure sensor 12, lower punch 2, cavity 21, porcelain powder 22, feeding tube 3, ceramic dielectric chip 4, ring convex part 41, disc concave part 42 , arc-shaped connection portion 43, feeding platform 5, feeding cart 6, second load cell 61, alarm device 62, storage tank 7, frame 8 and limit boss 9 and other main technical features.

[0028] Such as figure 2 As shown, the ceramic dielectric chip includes a concavity of a disk and a convex portion of a ring arranged coaxially, the concave portion of the disk is located inside the convex portion of the ring, and the thickness of the convex portion of the ring is 1.5 to 2 times the thickness of the concave portion of the disk; An arc-shaped connection part is provided at the junc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com