Chip breaking drill bit with step edge type

A step and drill technology, which is applied in step drilling, drill repairing, tool manufacturing, etc., can solve the problems that affect the processing efficiency and quality, the chip cannot be discharged smoothly in time, the tool is worn and damaged, etc., so as to facilitate the smooth discharge and ensure the workpiece Effect of machining surface quality and reducing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

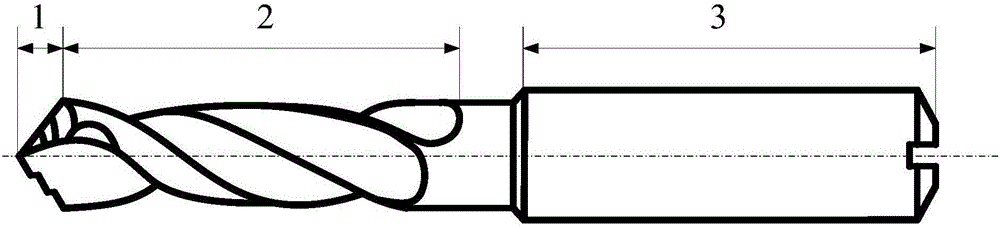

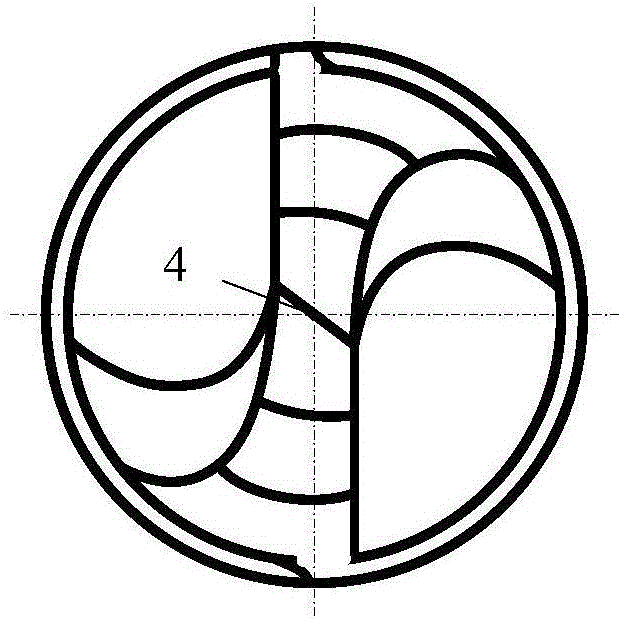

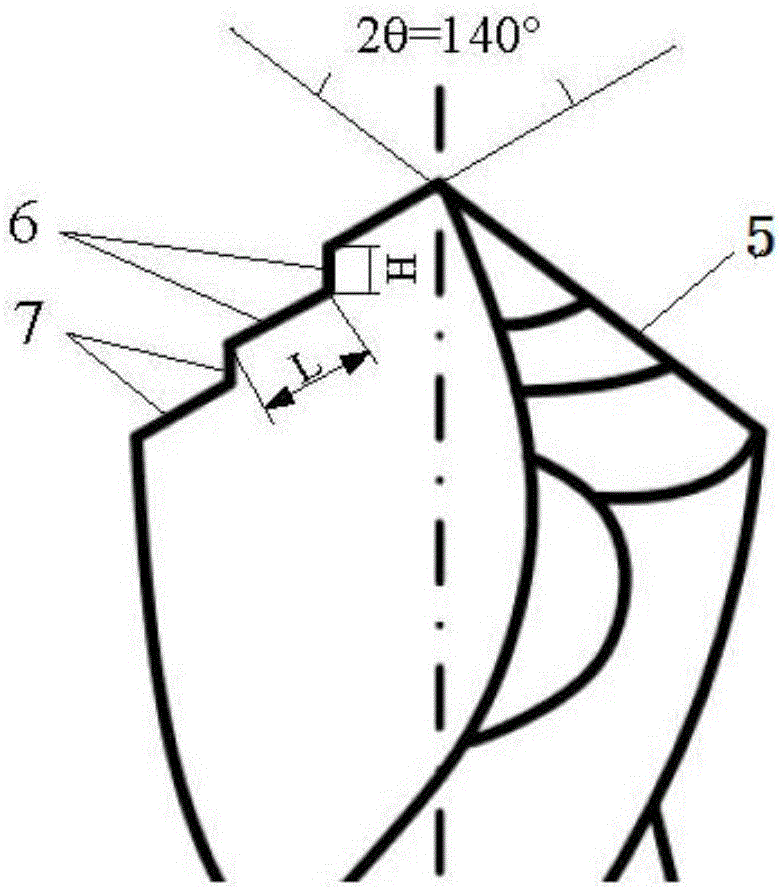

[0018] The chip breaking drill bit with stepped edge type of the present invention is made of cemented carbide, such as figure 1 , figure 2 and image 3 As shown, it mainly includes a drill tip 1 , a guide part 2 and a tool handle 3 , and the guide part 2 is arranged between the drill tip 1 and the tool handle 3 . The drill tip 1 includes a chisel edge 4 and two main cutting edges 5 . In order to adapt to the drilling of difficult-to-machine materials, the apex angle 2θ of the drill point is 140°, which reduces the load on the unit cutting edge and reduces tool wear. The helix angle of the guide part 2 is 40° to increase the space of the chip flute, avoid chip clogging and ensure the smooth discharge of chips.

[0019] The chisel edge 4 is located at the center of the drill point between the two main cutting edges 5. During the drilling process, a large torque will be generated due to the resistance of the material. In order to ensure the rigidity and strength of the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com