Method for casting large investment pattern through rapid reversing and 3D printing

A 3D printing and investment casting technology, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of high cost of consumables, difficulty in mastering technology, and inaccuracy, and achieve low labor costs, many people who master it, and easy The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

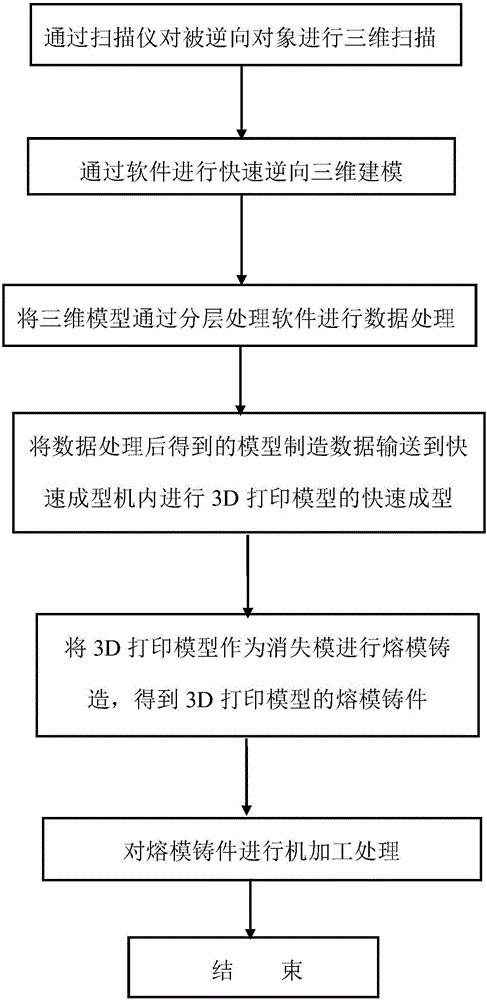

[0029] Such as figure 1 As shown, the rapid reverse and 3D printing large-scale investment casting method provided by the present invention comprises the following steps:

[0030] (1) Carry out three-dimensional scanning of the object to be reversed by a scanner;

[0031] (2) Three-dimensional modeling of the 3D printing model is carried out through three-dimensional software; after the three-dimensional modeling is completed, the three-dimensional model is enlarged according to the process requirements and the size of the 3D printing model is changed, and the processing allowance for machining is reserved.

[0032] (3) Data processing of the 3D model through layered processing software; data processing includes setting the forming direction and position of the 3D model, creating ribbed supports, and layering processing of the 3D model. After data processing, the output is a model manufacturing data format.

[0033] (4) Transport the model manufacturing data obtained after da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com