Visible-light responding photocatalytic material with Ag particles in different morphologies loaded on AgInO2 surface in situ and preparation method of visible-light responding photocatalytic material

A photocatalytic material and visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high recombination rate of photogenerated carriers and low quantum efficiency , many steps and other problems, to achieve the effect of simple preparation method, reduced recombination rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Preparation of AgInO 2

[0045] Prepare 0.01mol In(NO 3 ) 3 4.5H 2 O was added to 10ml of deionized water; 50ml of 10mol / L NaOH solution; 20ml of 0.5mol / L AgNO 3 solution.

[0046] Add 50ml of 10mol / L NaOH solution to the prepared In(NO 3 ) 3 In the solution, stir rapidly until the solution is completely cooled to obtain a suspension; press AgNO 3 : In(NO 3 ) 3 =1.0 molar ratio, 20ml 0.5mol / L AgNO 3 Add the solution dropwise to the above suspension, stir while adding dropwise, and continue stirring for 1 hour after the dropwise addition; transfer the solution to a polytetrafluoroethylene-lined reactor with a total volume of 120ml, with a filling degree of 70-80% volume Ratio, react at 200°C for 48h; after the reaction, cool to room temperature, wash with deionized water and absolute ethanol, and dry at 60°C for 12h to obtain the micronano orange powder material AgInO 2 .

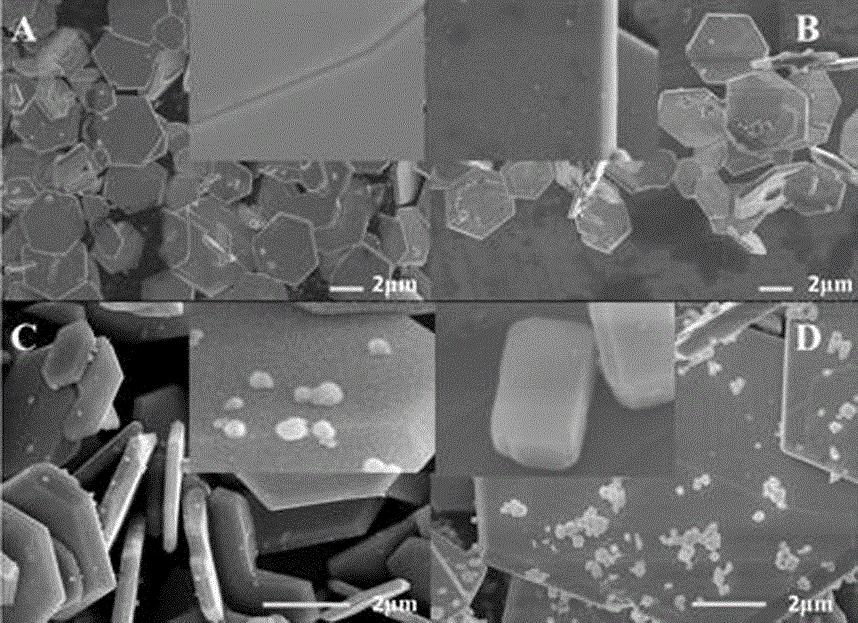

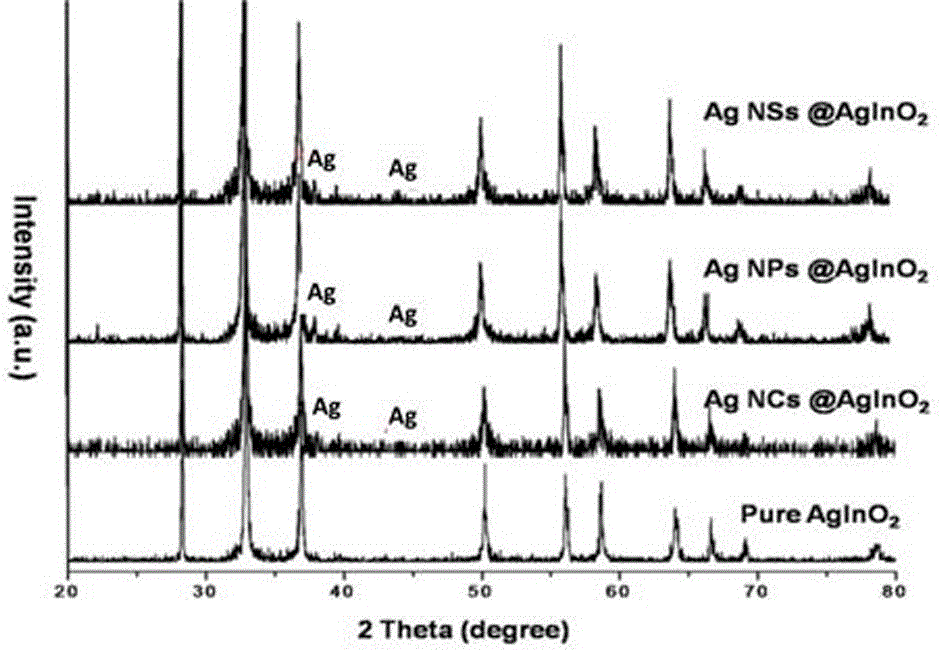

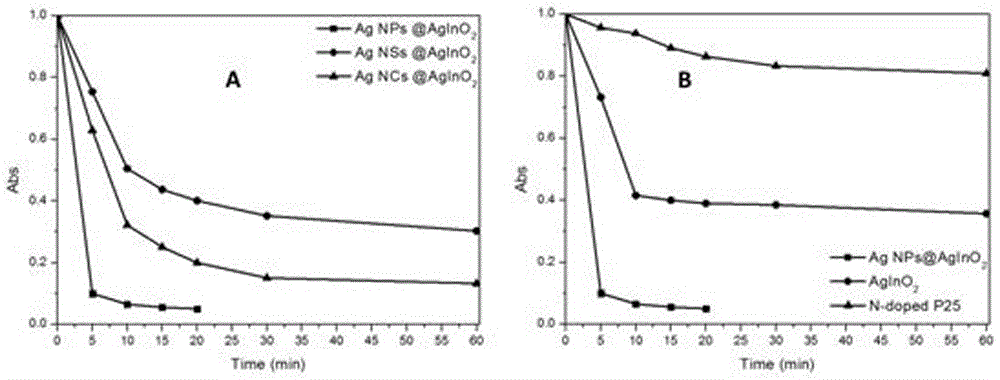

[0047] Embodiment 1 micronano powder material AgInO 2 , electron micro...

Embodiment 2

[0048] Embodiment 2: Preparation of AgInO 2

[0049] Prepare 0.01mol In(NO 3 ) 3 4.5H 2 O was added to 10ml of deionized water; 50ml of 10mol / L NaOH solution; 20ml of 0.5mol / L AgNO 3 solution.

[0050] Add 50ml of 5mol / L NaOH solution to the prepared In(NO 3 ) 3 In the solution, stir rapidly until the solution is completely cooled to obtain a suspension; press AgNO 3 : In(NO 3 ) 3 =1.0 molar ratio, 20ml 0.5mol / L AgNO 3 Add the solution dropwise to the above suspension, stir while adding dropwise, and continue stirring for 1 hour after the dropwise addition; transfer the solution to a polytetrafluoroethylene-lined reactor with a total volume of 120ml, with a filling degree of 70%-80% Volume ratio, react at 190°C for 60h. After the reaction, cool to room temperature, wash with deionized water and absolute ethanol, and dry at 60°C for 12 hours to obtain the micronano orange powder material AgInO 2 .

[0051] The topography of the sample that embodiment 2 obtains is ...

Embodiment 3

[0052] Embodiment 3: Preparation of AgInO 2

[0053] Prepare 0.01mol In(NO 3 ) 3 4.5H 2 O was added to 10ml of deionized water; 50ml of 10mol / L NaOH solution; 20ml of 0.5mol / L AgNO 3 solution.

[0054] Add 50ml of 10mol / L NaOH solution to the prepared In(NO 3 ) 3 In the solution, stir rapidly until the solution is completely cooled to obtain a suspension; press AgNO 3 : In(NO 3 ) 3 =1.05 molar ratio, 20 ml 0.5mol / L AgNO 3 Add the solution dropwise to the above suspension, stir while adding dropwise, and continue stirring for 1 hour after the dropwise addition; transfer the solution to a polytetrafluoroethylene-lined reactor with a total volume of 120 ml, with a filling degree of 70-80% Volume ratio, react at 220°C for 24h; after the reaction, cool to room temperature, wash with deionized water and absolute ethanol, and dry at 60°C for 12h to obtain the micronano orange powder material AgInO 2 .

[0055] Embodiment 3 micronano powder material AgInO 2 , electron mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com