Acellular tissue matrix composite and preparation method thereof

An acellular tissue and composite material technology, applied in the field of acellular tissue matrix composite materials and their preparation, can solve the problems of difficult regulation of degradation time and three-dimensional structure, poor mechanical strength, loss of active components, etc., to promote adhesion and migration. and proliferation, improved mechanical properties, high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

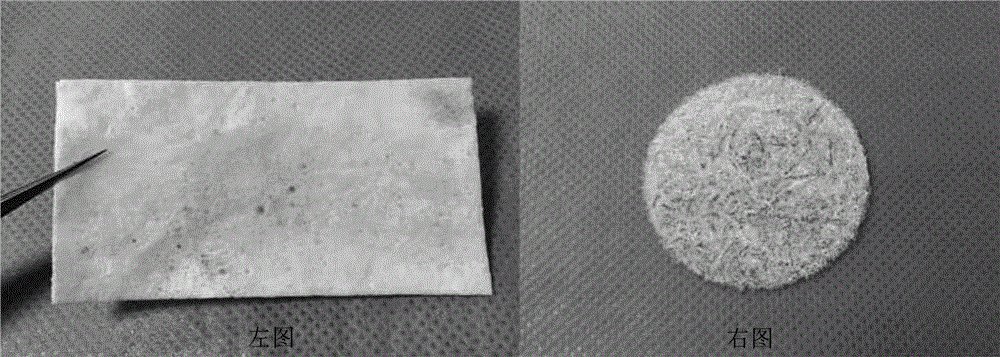

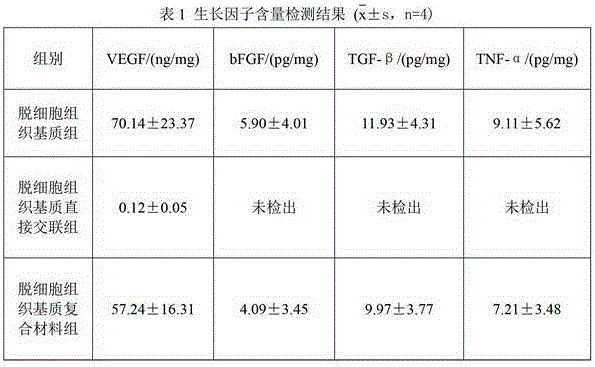

[0039] Acellular tissue matrix composite material: take the wet weight of 100g of the acellular tissue matrix after decellularization of porcine small intestinal submucosa tissue, crush it, add 100ml sterile water for injection, mix it with 4g hyaluronic acid, pour it into a mold, freeze A porous sheet-like acellular tissue-matrix composite material with a thickness of 2 mm was dried. Weigh 0.2g of NHS and 1.92g of EDC and dissolve in 20ml of 0.1mol / L citric acid / sodium citrate buffer (PH=5.4), add 180ml of ethanol after complete dissolution, and mix well to obtain a cross-linking agent solution. Put into the cross-linking agent solution prepared above for cross-linking for 1 hour, then rinse with sterile water for injection to remove the residual cross-linking agent, and freeze-dry to obtain the acellular tissue matrix composite material.

[0040] The obtained product is used for the surface of the body, is used for soft tissue repair, has the functions of promoting wound hea...

Embodiment 2

[0042] Acellular tissue matrix composite material: Take 100g wet weight of acellular tissue matrix after decellularization of porcine small intestinal submucosa tissue, crush it, add 100ml of 0.01mol / L HCl containing 100mg pepsin (2000~2300U / mg) In the solution, keep constant stirring at room temperature (25°C) for 48 hours, the pH of the viscous solution obtained by enzymatic digestion is about 3.0-4.0, and the pH is raised to 7.4 with NaOH solution, the activity of pepsin is irreversibly inactivated, and the obtained The acellular tissue matrix enzyme digestion solution was evenly mixed with 4 g of sodium alginate, poured into a mold, and freeze-dried to obtain a 2 mm thick porous sheet-like composite material. The scaffold is cross-linked with 0.05 g / ml calcium chloride solution for 10 minutes, washed with sterilized water for injection to remove residual calcium chloride, and freeze-dried to obtain the acellular tissue matrix composite material.

[0043] The obtained produ...

Embodiment 3

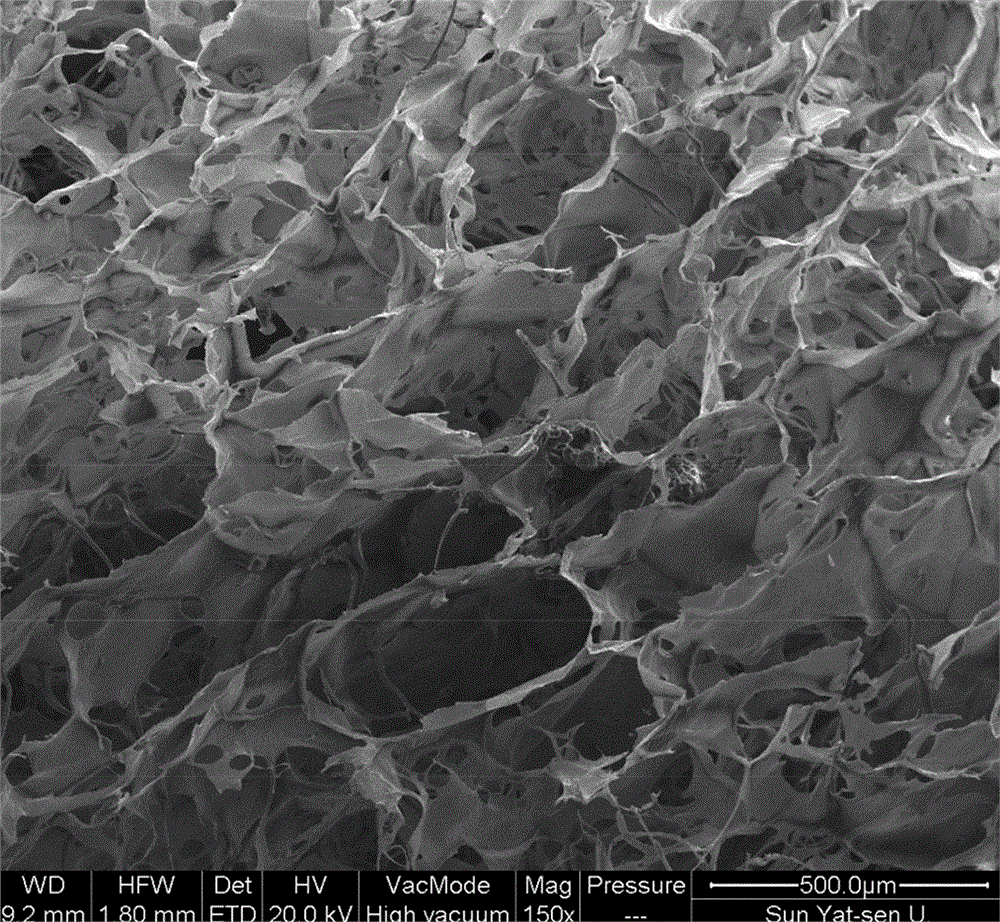

[0045] Acellular tissue matrix composite material: Take the wet weight of 100g of the acellular tissue matrix after decellularization of porcine small intestinal submucosa tissue, crush it, add 100ml of sterile water for injection, mix it with 4g of sodium alginate, pour it into a mold, freeze A porous sheet-like acellular tissue-matrix composite material with a thickness of 2 mm was dried.

[0046] The obtained product is used for the surface of the body, is used for soft tissue repair, has the functions of promoting wound healing and promoting blood vessel regeneration, and the degradation time is 1 to 2 weeks. The obtained product is in the shape of a sponge with a micropore size of 20-800 microns and a porosity of 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore size | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com