Nonaqueous electrolyte secondary battery

A non-aqueous electrolyte, secondary battery technology, applied in non-aqueous electrolyte storage batteries, secondary batteries, electrolytes, etc., can solve the problems of the deterioration of the crystal structure of the positive electrode active material, the reaction between the positive electrode active material and the non-aqueous electrolyte, etc. The effect of structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

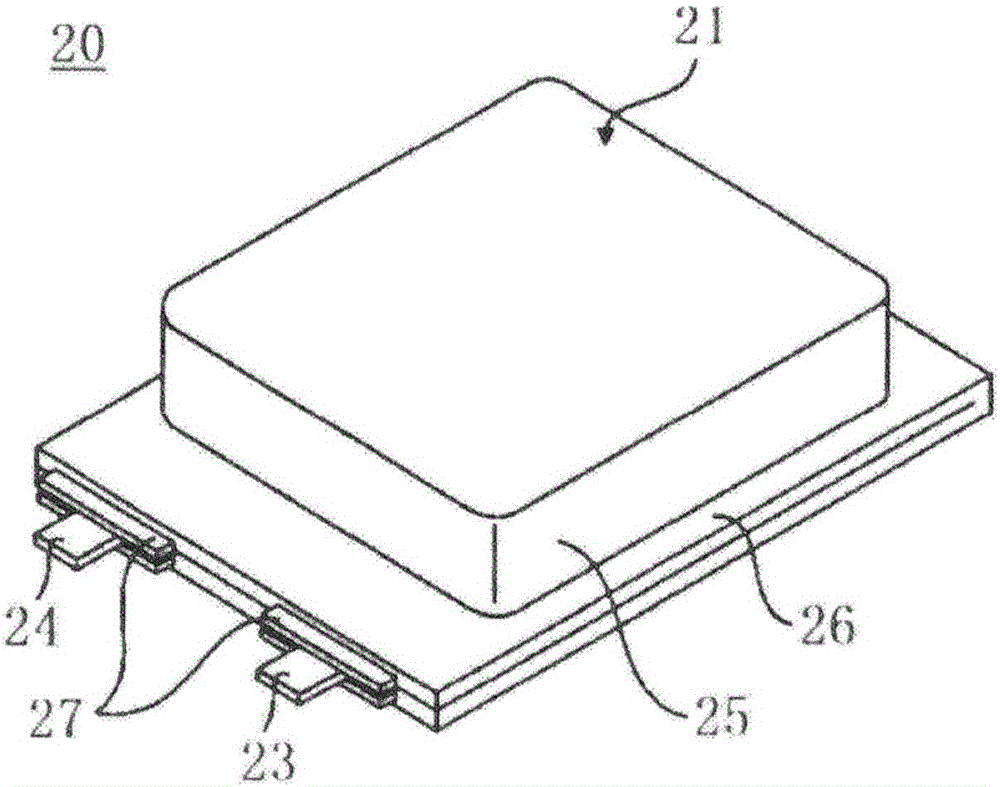

Image

Examples

Embodiment 1

[0037] [making of positive electrode]

[0038] The positive electrode active material was produced as follows. Lithium carbonate was used as a lithium source, cobalt tetroxide was used as a cobalt source, and nickel hydroxide, manganese dioxide, and aluminum hydroxide were used as nickel, manganese, and aluminum sources serving as cobalt replacement element sources. After dry mixing cobalt, nickel, manganese and aluminum at a molar ratio of 84:10:5:1, it is mixed with lithium carbonate at a molar ratio of lithium and transition metals of 1:1, and the powder is formed into granules , in an air atmosphere, calcined at 900° C. for 24 hours to prepare a positive electrode active material.

[0039] Next, a rare earth compound is attached to the surface by a wet method as described below. 1000 g of the positive electrode active material and 3 liters of pure water were mixed and stirred to prepare a suspension in which the positive electrode active material was dispersed. While ad...

Embodiment 2

[0055] Battery A2 was fabricated in the same manner as in Example 1 except that the molar ratio of cobalt, nickel, manganese, and aluminum was 79:15:5:1 to prepare the positive electrode active material.

Embodiment 3

[0057] Battery A3 was fabricated in the same manner as in Example 1 except that the molar ratio of cobalt, nickel, manganese, and aluminum was 68:25:5:2 to prepare the positive electrode active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com