Ni ball, ni core ball, solder joint, solder paste, and solder foam

A core ball, sphericity technology, applied in the field of solder paste and forming solder, Ni ball, Ni core ball, brazing joint, can solve the problem of solder ball crushing, unable to maintain the proper space of the substrate, etc., to improve the resistance to drop impact performance, suppressing unevenness in height, and ensuring the effect of automatic alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Hereinafter, examples of the present invention will be described, but the present invention is not limited thereto. In this example, Ni balls with high sphericity were produced, and the Vickers hardness and α-ray dose of the produced Ni balls were measured.

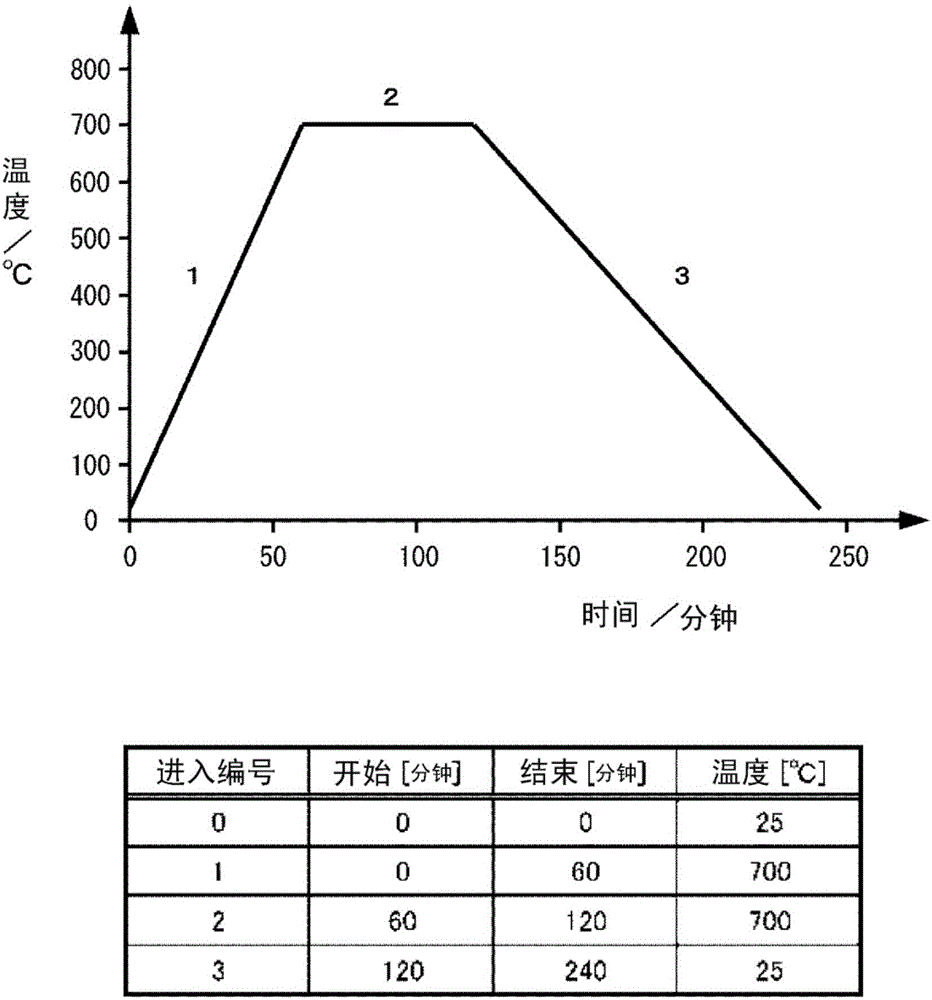

[0083] ·Ni ball making

[0084] Study the production conditions of Ni balls with high sphericity. Prepare Ni wire with a purity of 99.9% (α-ray dose: 0.0034cph / cm 2 , U: 0.7ppb, Th: 0.5ppb), Ni wire with a purity of 99.995 or less (α-ray dose: 0.0026cph / cm 2 , U: <0.5ppb, Th: <0.5ppb). Each Ni wire was put into a crucible, and it preheated for 45 minutes under the temperature condition of 1000 degreeC. Then, the spraying temperature is set to 1600° C., preferably 1700° C., and liquid molten Ni is sprayed from a nozzle at a high speed by a gas atomization method, and the sprayed molten Ni is rapidly cooled to room temperature (18° C.), So as to make Ni balls. Thus, Ni balls having an average particle diameter ...

Embodiment 2

[0100] In Example 2, Ni balls produced from Ni wires having a purity of 99.995% or less shown in Table 1 were annealed and oxide film removed in the same manner as in Example 1. Then, the Vickers hardness of the obtained Ni balls was measured. In addition, the sphericity and α-ray dose of the Ni balls after the annealing treatment were measured by the above-mentioned methods, respectively. These measurement results are shown in Table 2 below.

Embodiment 3

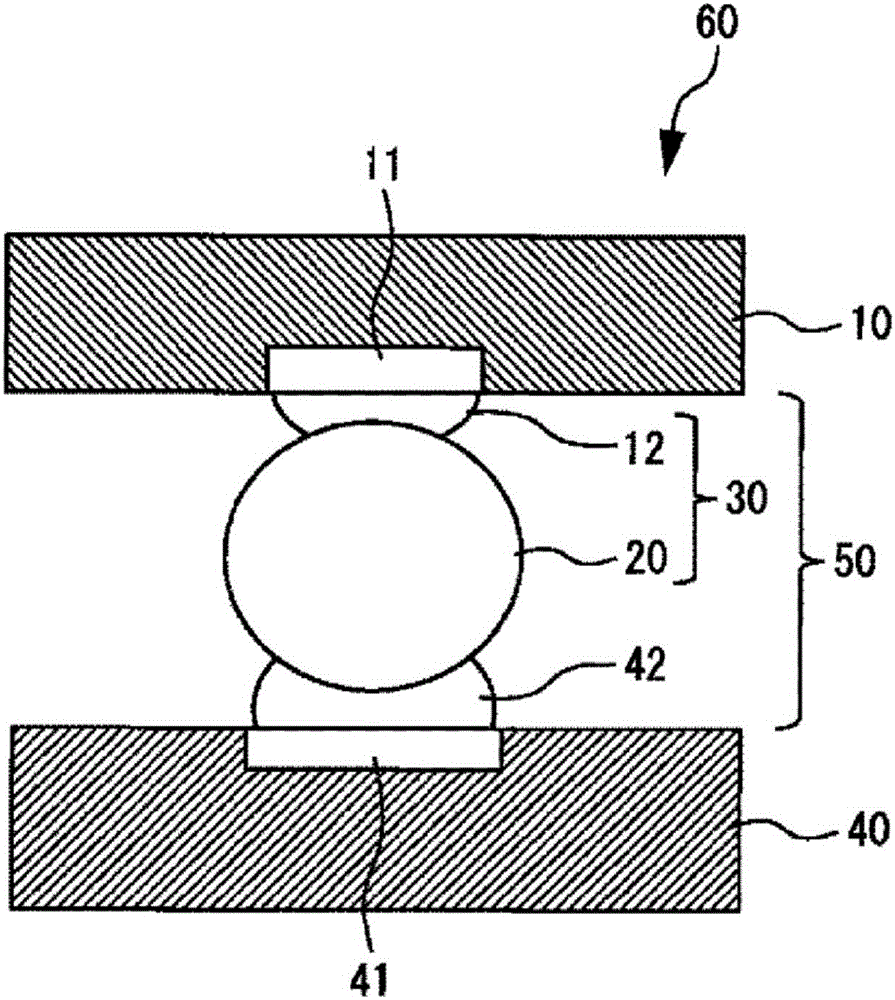

[0114] Next, the sphericity and α-ray dose of the Ni core balls obtained using the above-mentioned Ni balls before and after the annealing treatment will be described. In Example 3, the sphericity and α-ray dose of the Ni core ball produced by coating the surface of the annealed Ni ball in Example 1 with a Ni plating layer of 1 μm on one side were measured by the above method. These measurement results are shown in Table 3 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com