Tungsten carbide-embedded carbon nanofiber composite membrane and preparation and application thereof

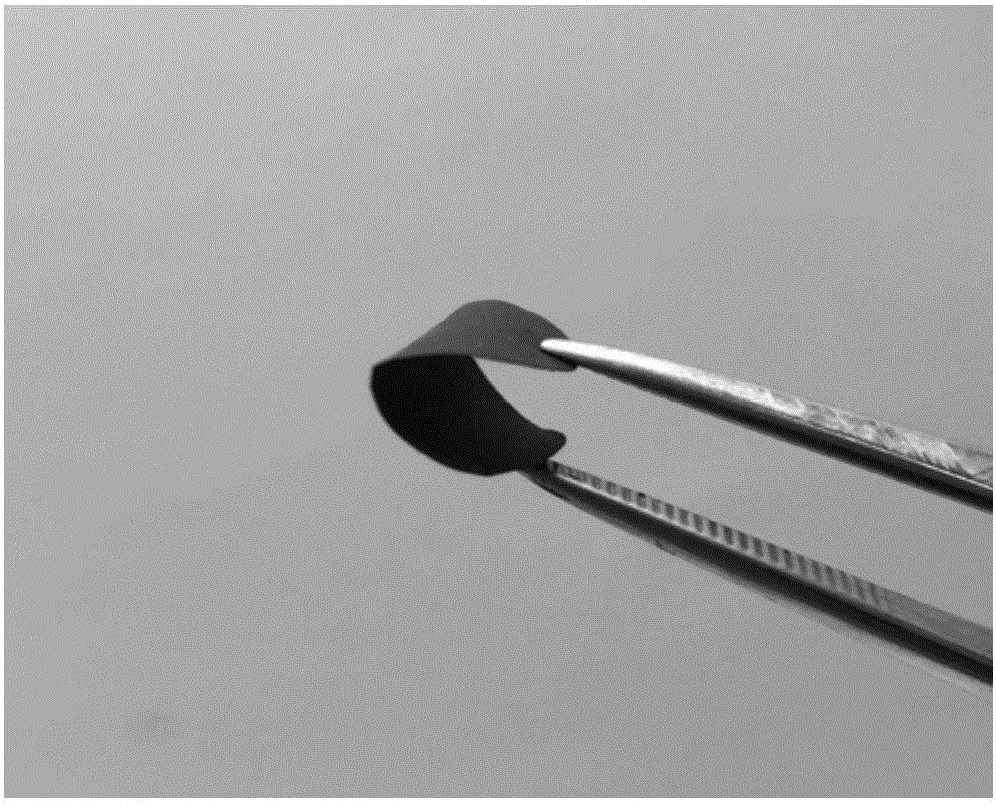

A technology of carbon nanofiber and tungsten carbide, which is applied in the field of carbon nanofiber composite film and its preparation and application, can solve the problems affecting the cycle stability of electrochemical active energy storage, the active sites cannot be fully exposed, etc., and achieve excellent electrical conductivity properties and electrochemical activity, inhibition of electrode material collapse, and ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

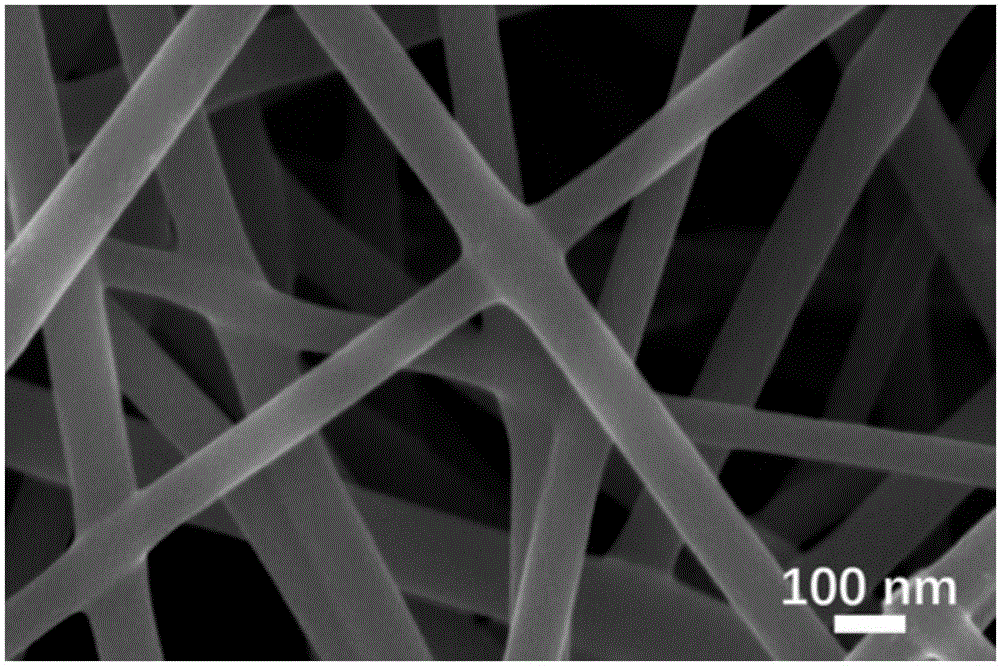

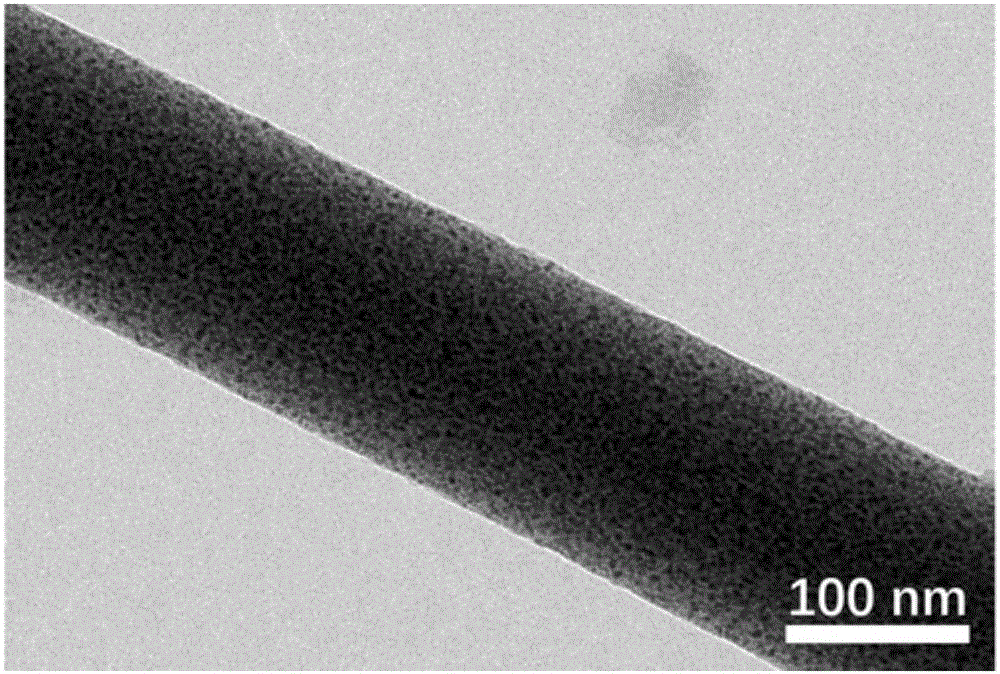

[0038] (1) Add 0.75g ammonium tetrathiotungstate and 0.5g polyacrylonitrile powder into 5mL N,N-dimethylformamide solvent, and keep stirring to obtain a uniform viscous dispersion;

[0039] (2) Electrospinning is performed on the obtained dispersion liquid, and its adjustment process parameters are: electrostatic field voltage 20kV, spinning speed 0.1mmmin -1 , the receiving distance is 20cm, and ammonium tetrathiotungstate / polyacrylonitrile spinning membrane is obtained;

[0040] (3) Pre-oxidize the obtained spun film under air atmosphere, the pre-oxidation temperature is 250°C, and the heating rate is 2°C min -1 , the pre-oxidation constant temperature time is 2h, and the pre-oxidized ammonium tetrathiotungstate / polyacrylonitrile composite film is obtained;

[0041](4) The pre-oxidized ammonium tetrathiotungstate / polyacrylonitrile composite film was subjected to high-temperature carbonization in one step in an argon-hydrogen atmosphere. The heat treatment temperature was 70...

Embodiment 2

[0045] (1) Add 1g ammonium tetrathiotungstate and 0.5g polyacrylonitrile powder into 5mL N,N-dimethylformamide solvent, and keep stirring to obtain a uniform viscous dispersion;

[0046] (2) Electrospinning is performed on the obtained dispersion liquid, and its adjustment process parameters are: electrostatic field voltage 20kV, spinning speed 0.1mmmin -1 , the receiving distance is 20cm, and ammonium tetrathiotungstate / polyacrylonitrile spinning membrane is obtained;

[0047] (3) Pre-oxidize the obtained spun film under air atmosphere, the pre-oxidation temperature is 250°C, and the heating rate is 2°C min -1 , the pre-oxidation constant temperature time is 2h, and the pre-oxidized ammonium tetrathiotungstate / polyacrylonitrile composite film is obtained;

[0048] (4) The pre-oxidized ammonium tetrathiotungstate / polyacrylonitrile composite film was subjected to high-temperature carbonization in one step in an argon-hydrogen atmosphere. The heat treatment temperature was 700°...

Embodiment 3

[0050] (1) Add 0.75g ammonium tetrathiotungstate and 0.5g polyacrylonitrile powder into 5mL N,N-dimethylformamide solvent, and keep stirring to obtain a uniform viscous dispersion;

[0051] (2) Electrospinning is performed on the obtained dispersion liquid, and its adjustment process parameters are: electrostatic field voltage 20kV, spinning speed 0.1mmmin -1 , the receiving distance is 20cm, and ammonium tetrathiotungstate / polyacrylonitrile spinning membrane is obtained;

[0052] (3) Pre-oxidize the obtained spun film under air atmosphere, the pre-oxidation temperature is 250°C, and the heating rate is 2°C min -1 , the pre-oxidation constant temperature time is 2h, and the pre-oxidized ammonium tetrathiotungstate / polyacrylonitrile composite film is obtained;

[0053] (4) The obtained pre-oxidized ammonium tetrathiotungstate / polyacrylonitrile composite film was subjected to high-temperature carbonization in one step in an argon-hydrogen atmosphere, the heat treatment temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com