Preparation method for negative electrode active materials and capacitors

A technology of negative electrode active material and positive electrode active material, which is applied in the field of capacitors and can solve the problems of low energy density of electrochemical hybrid capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

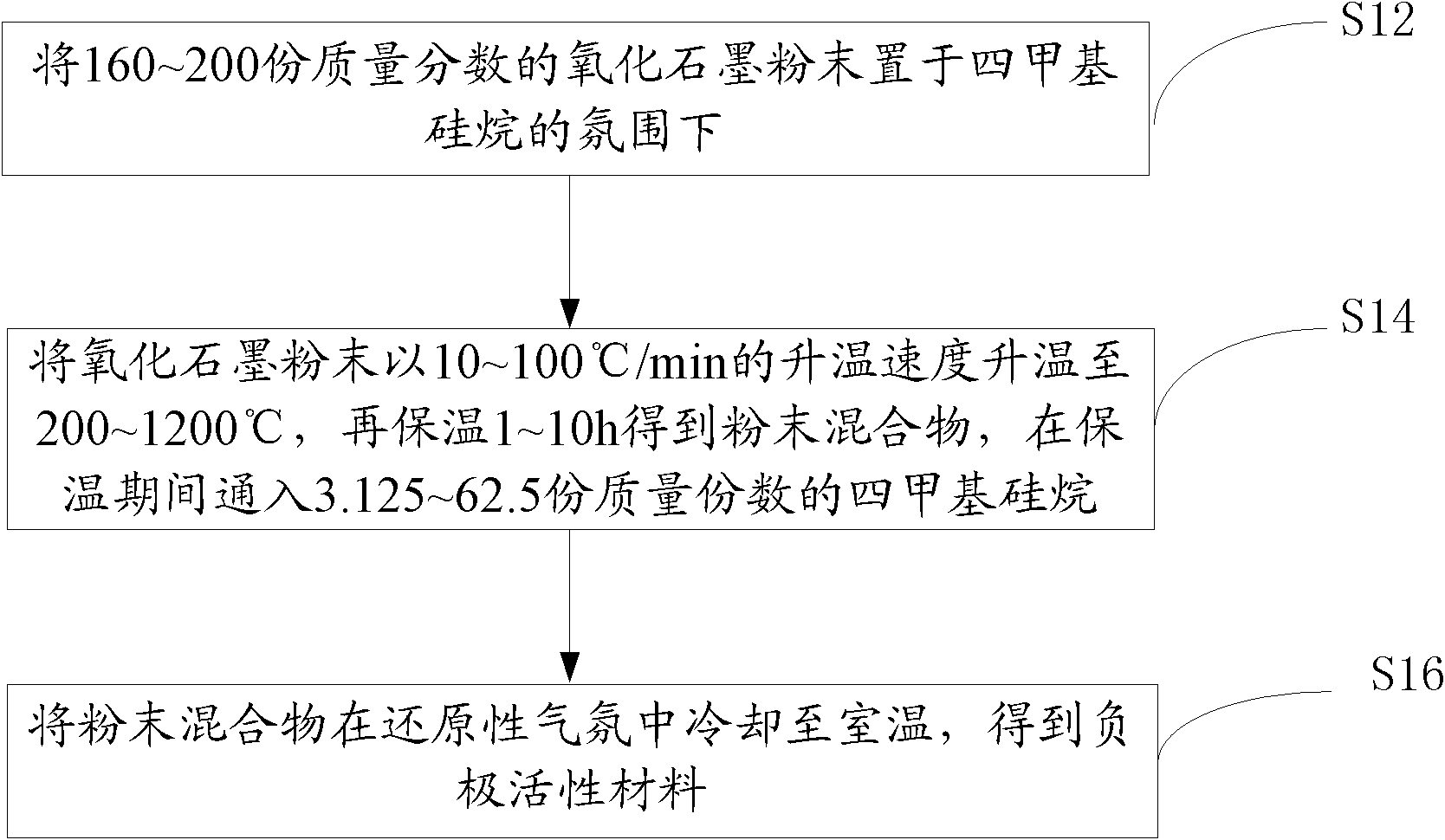

[0019] see figure 1 , the preparation method of the negative electrode active material of an embodiment, comprises the following steps:

[0020] Step S12, placing 160-200 parts by mass of graphite oxide powder in an atmosphere of tetramethylsilane.

[0021] In this embodiment, the reaction is carried out in a tube furnace.

[0022] Step S14, heat up the graphite oxide powder to 200-1200°C at a heating rate of 10-100°C / min, and then keep it warm for 1-10 hours to obtain a powder mixture, and pass 3.125-62.5 parts by mass of tetramethylsilane during the heat preservation period .

[0023] Step S16, cooling the powder mixture to room temperature in a reducing atmosphere to obtain a negative electrode active material.

[0024] In this embodiment, the reducing atmosphere is a hydrogen atmosphere.

[0025] In this embodiment, natural cooling is adopted when cooling the powder mixture to room temperature.

[0026] The preparation method of the above-mentioned negative electrode ...

Embodiment 1

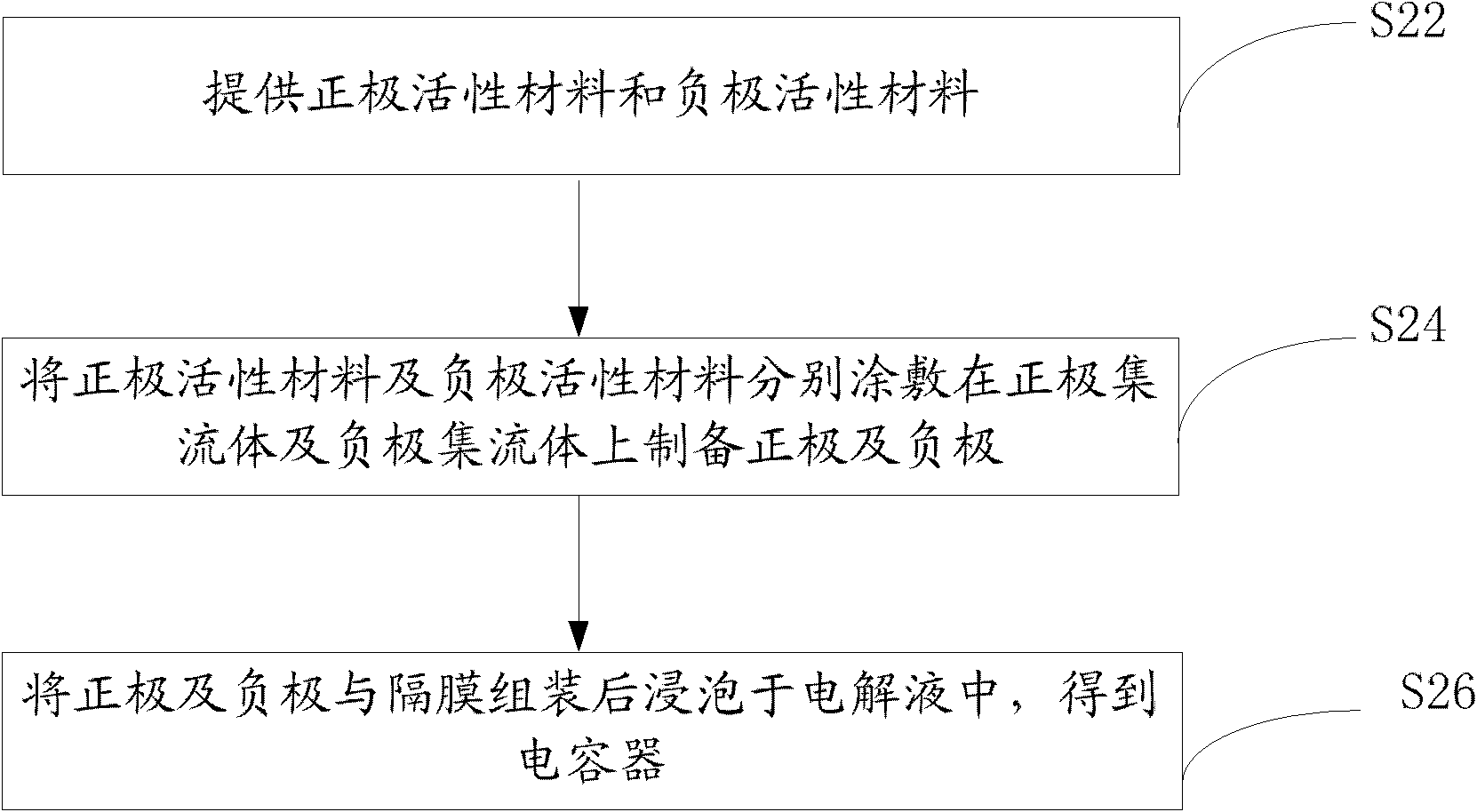

[0041] Positive electrode: The positive electrode active material activated carbon, binder (PVDF) and conductive agent (acetylene black) are mixed in a mass ratio of 85:10:5 to form a positive electrode material, and a solvent (NMP) is added to form a viscosity of 2500 Newton seconds / square meter Positive electrode slurry, the positive electrode slurry is coated on the aluminum foil, and then dried, rolled and cut to make the positive electrode.

[0042] Negative electrode: (1) Put 200 parts of graphite oxide powder into a tube furnace with tetramethylsilane, raise the temperature of the tube furnace to 1000 °C at a heating rate of 50 °C / min, and heat for 5 hours to obtain a powder mixture, Feed within 5h, feed 3.125 parts by mass of tetramethylsilane during the heat preservation period, then cool the powder mixture to room temperature in a hydrogen atmosphere to obtain a negative active electrode with a mass ratio of silicon nanowires to graphene of 1:99 Material; (2) The neg...

Embodiment 2

[0047] Positive electrode: active carbon and lithium iron phosphate material with a mass ratio of 70:30 are prepared as the positive electrode active material. The prepared positive electrode active material is mixed with a binder (PVDF) and a conductive agent (conductive carbon black super P) in a mass ratio of 90:5:5 to form a positive electrode material, and a solvent (NMP) is added to form a viscosity of 1500 Ns / Square meters of positive electrode slurry, the positive electrode slurry is coated on aluminum foil, and then dried, rolled and cut to make positive electrodes.

[0048] Negative electrode: (1) Put 160 parts of graphite oxide powder into a tube furnace with tetramethylsilane, raise the temperature of the tube furnace to 1200 °C at a heating rate of 100 °C / min, and heat for 10 hours to obtain a powder mixture, Pass into 62.5 parts of quality tetramethylsilane during the heat preservation period, then the powder mixture is cooled to room temperature in a hydrogen a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com