Novel three-dimensional microwave multi-chip module structure

A microwave multi-chip and component structure technology, applied in electrical components, electric solid-state devices, semiconductor devices, etc., can solve the problems of unsuitable mass production, increased component volume, low production efficiency, etc., to improve system integration, reduce Component volume, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

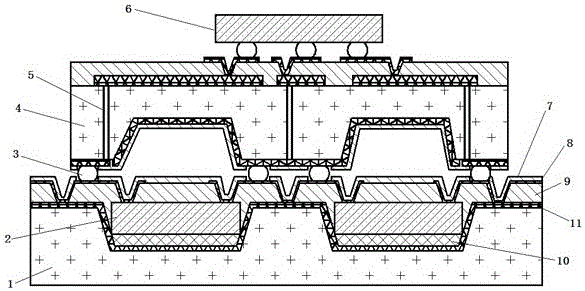

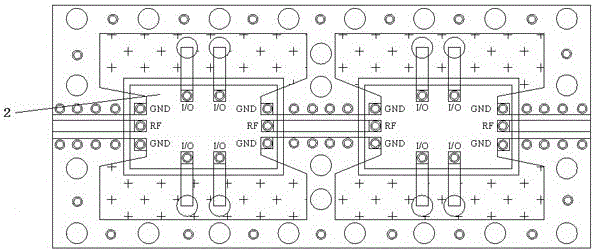

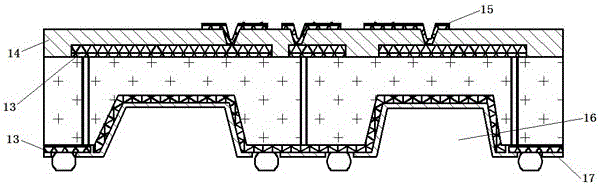

[0019] Such as figure 1 As shown, the present invention discloses a novel three-dimensional microwave multi-chip assembly structure, which includes a bottom silicon chip 1, an MMIC chip 2, a top layer silicon chip 4, and an ASIC chip 6 from bottom to top; the bottom silicon chip 1 is etched with a chip Install groove, and electroplate the first metal layer 11 on the surface, MMIC chip 2 is bonded on the bottom of the chip installation groove by conductive adhesive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com