Manufacturing process of sealing cutter for heat shrinkage film cloth roll packaging machine

A production process and packaging machine technology, which is applied in the production process field of sealing and cutting knives for heat-shrinkable film cloth roll packaging machines, can solve the problems of sealing effect, high cost, and difficult assembly, so as to ensure cleanliness and aesthetics, temperature The effect of high accuracy and saving mold opening cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

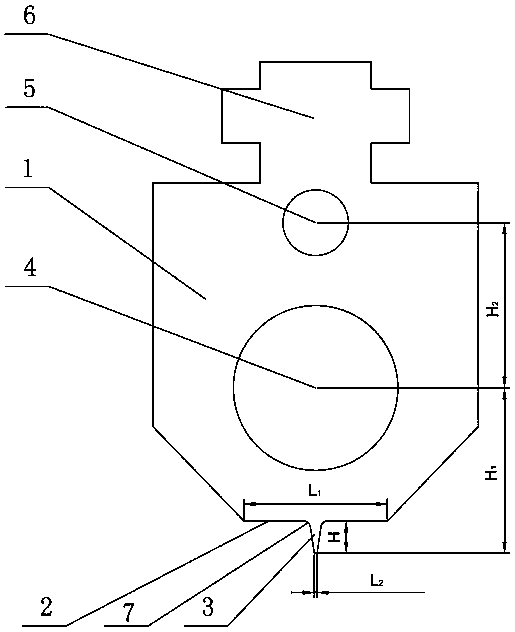

[0011] Embodiment 1: As shown in Figure 1, a manufacturing process of a sealing and cutting knife for a heat-shrinkable film cloth roll packaging machine, including a base 1, the lower end surface of the base 1 is a sealing surface 2, and the sealing surface 2 is a plane. The sealing surface 2 is integrally provided with a raised rib 3, which has the same length as the sealing surface 2 and divides the sealing surface 2 into two parts with the same width; the base 1 is provided with a heat pipe installation hole 4 and a thermocouple The installation hole 5, the center of the heat pipe installation hole 4 and the center line of the thermocouple installation hole 5 coincide with the central axis of the rib 3, and the vertical distance H1 from the center of the heat pipe installation hole 4 to the top of the rib 3 is the same as that of the thermocouple installation The vertical distance H2 from the center of the hole 5 to the top of the rib 3 is equal.

[0012] In this specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com