Assembly type molten salt reactor

A molten salt reactor and component technology, applied in the directions of reactors, reactor fuel elements, moderators/core structures, etc., can solve the problems of unfavorable safe operation of the reactor, large number of fuel rods, and inability to be practically applied, so as to solve the problems of uranium resources. Scarcity, efficient recycling and management, effectiveness in solving energy problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, a module-type molten salt reactor core with a power of 1GW is taken as an example.

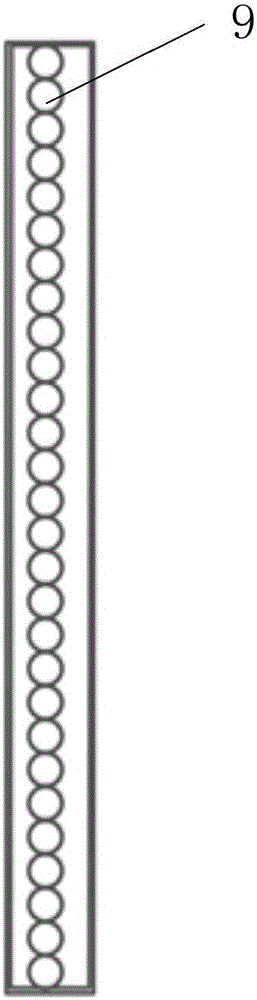

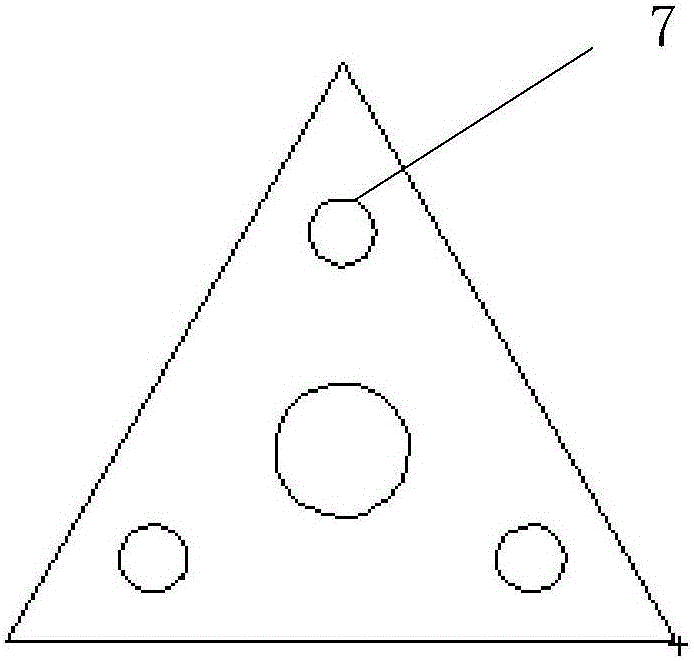

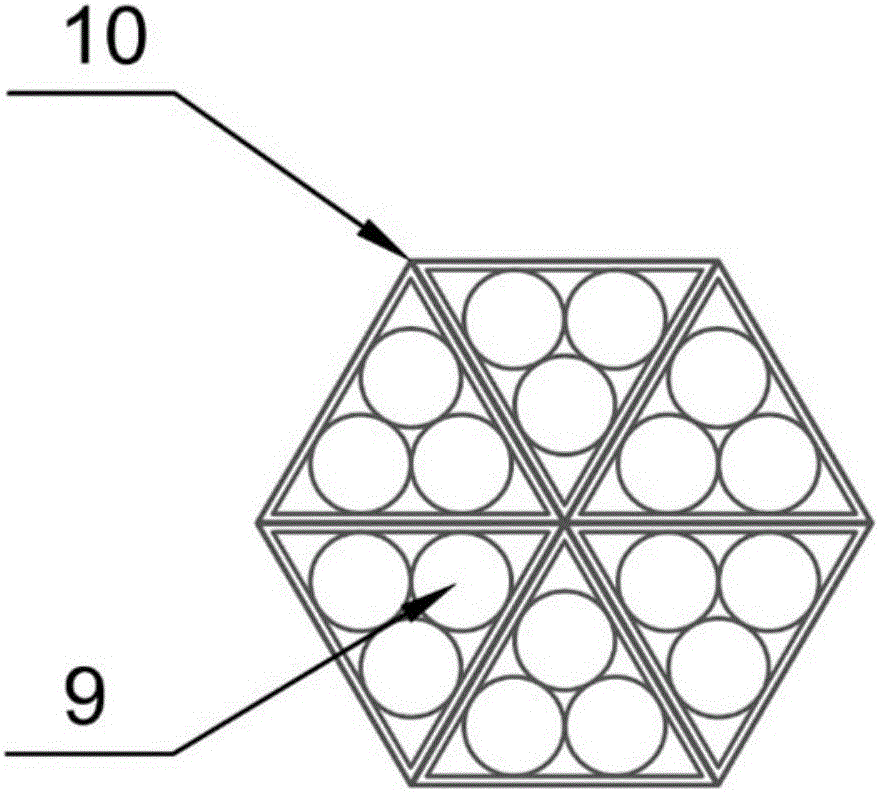

[0044] figure 1 is a longitudinal section view of a regular triangular prism fuel assembly; figure 2 It is a cross-sectional schematic diagram of the molten salt circulation channels on the top and bottom surfaces of the regular triangular prism fuel assembly; image 3 is a cross-sectional schematic diagram of structure 1; Figure 4 It is a cross-sectional schematic diagram of structure 2. There are 28 layers of fuel balls in Structure 2 1, and each layer has three layers. The top and bottom of the regular triangular prism have and figure 2 The same molten salt flow channel. They are the most important basic structures of the core. The fuel hexagonal prism structural unit is composed of six triangular prism fuel assemblies, and the hexagonal prism structural unit containing the control rod channel is composed of 5 fuel assemblies and a control rod channel 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com