Method for recycling drawing oil

A wire drawing oil and wire drawing machine technology, which is applied in the field of wire drawing oil recycling, can solve problems such as unsatisfactory lubrication effect, no cooling effect, and loss of damage, and achieve low production costs, avoid pollution, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A method for recycling drawing oil, the method comprises the following steps:

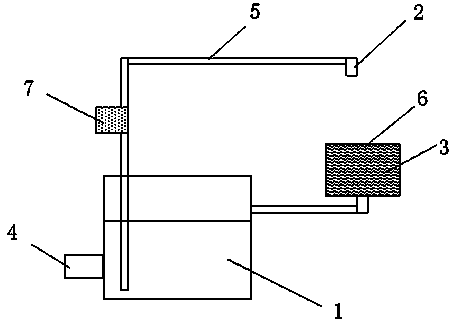

[0014] 1) Install a circulation processing device at the bare copper flat wire of the wire drawing machine, see figure 1 It includes an oil storage tank 1, a spray head 2, a collection tank 3 and an oil pump 4. The spray head 1 is connected to the oil storage tank 1 through a pipeline 5. The oil storage tank is arranged underground next to the wire drawing machine and is an underground oil storage tank. The underground oil storage tank is convenient for cooling the solution, and also ensures that the solution will not freeze in winter; in addition, it also prevents the solution from being polluted. The oil pump 4 used to extract the solution in the oil storage tank 1 is connected with the oil storage tank 1 . The spray head 2 is located above the bare copper flat wire of the wire drawing machine, and the wire drawing oil is mixed with the water ditch and then sprayed onto the bare copper fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com