Heat-pump-type heat-recovery tobacco drying device controlled by computer

A technology of computer control and drying device, which is applied in the direction of heating device, tobacco drying, drying gas arrangement, etc., which can solve the problems of low efficiency, high energy consumption, unfavorable development of tobacco leaf industrialization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

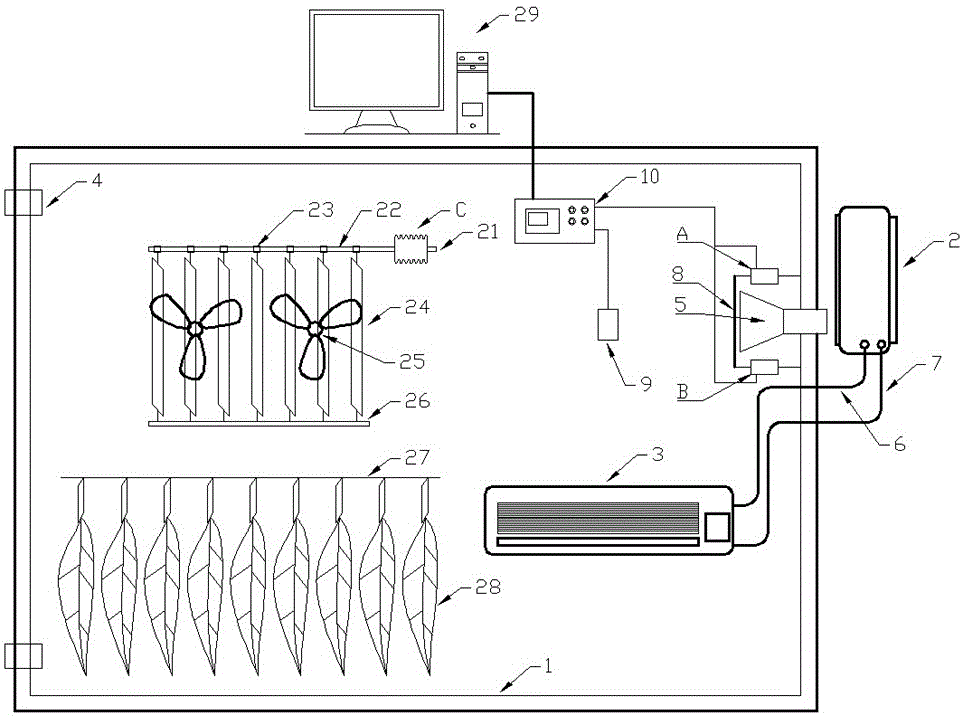

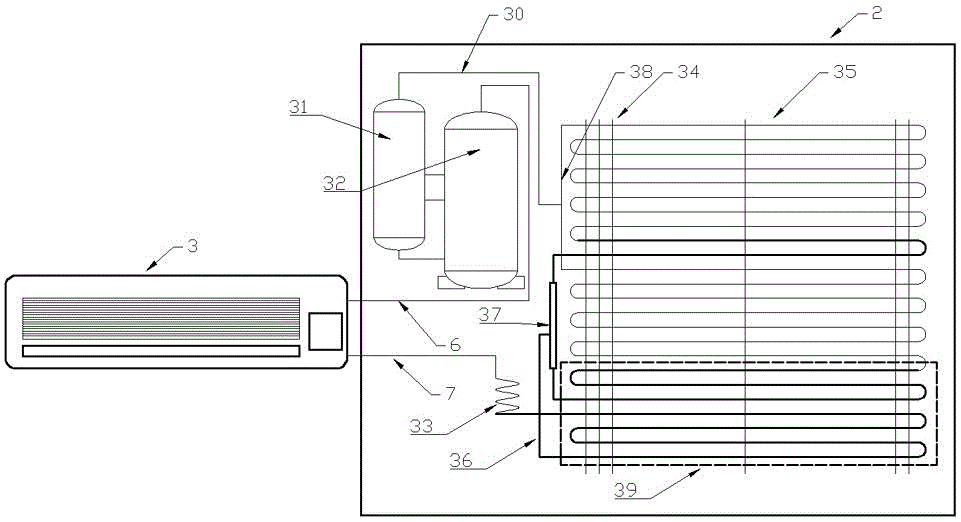

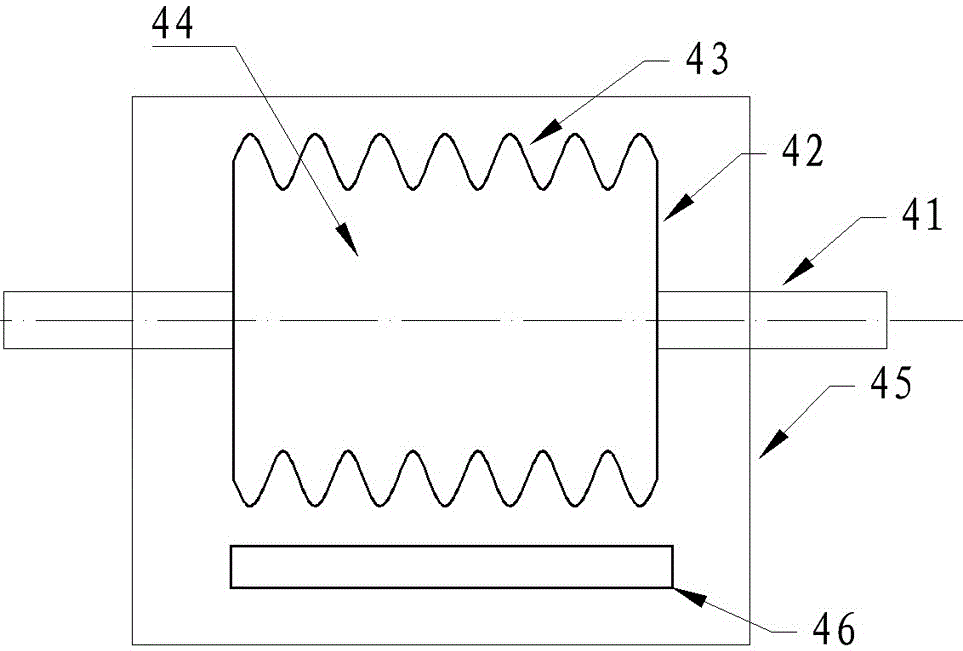

[0017] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0018] like Figure 1-4 The shown computer-controlled heat pump heat recovery tobacco leaf drying device includes a heat pump inner unit 3, an outer unit 2, and an insulation enclosure 1. The structure of the heat pump outer unit 2 is similar to that of an air conditioner, and the refrigerant vapor from the coil of the outer unit passes through a pipe 30. It enters the gas-liquid separator 31 to separate the liquid phase, and then is compressed by the compressor 32 and connected to the internal unit 3 through the pipeline 6. The structure of the internal unit is the same as that of an ordinary air conditioner, and it acts as a condenser here to realize the liquefaction of the compressed gas and release a large amount of heat for supply. The material is dry, and the high-pressure condensed and liquefied refrigerant enters the lower coil through the liquid return pipe 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com