Method for infiltrating titanium in a new reactor for producing sponge titanium

A technology of reactor and titanium sponge, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of long treatment cycle, low efficiency of titanium infiltration, unsatisfactory effect of titanium infiltration, etc., and shorten production Cycle time and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

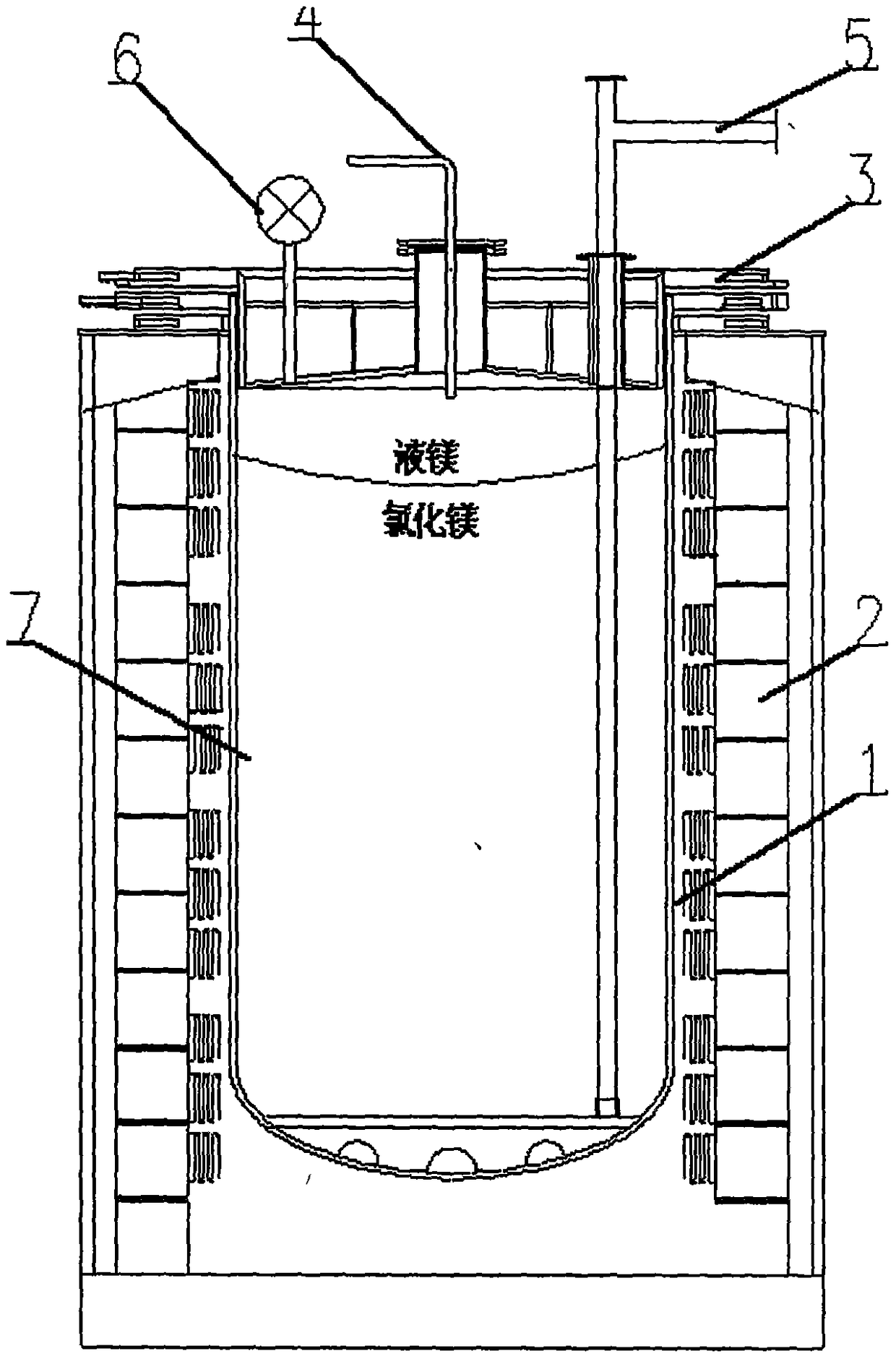

Embodiment 1

[0022] With a diameter of φ1500mm and a height of 3200mm, the effective space volume is 4.725m 3 Take the new reactor as an example. After immersing the inner wall 7 of the newly made reactor with 8% dilute hydrochloric acid for 8 days, rinse the inner surface with clean water to reveal the metallic luster, and use compressed air to quickly dry the surface. Add 33075m to the reactor 3 (weight is 5.53 tons) magnesium chloride and 500kg magnesium ingot, assembles reactor. Start the vacuum pump to degas the reactor for 2 hours and then fill it with argon for protection; the purity of magnesium chloride is above 99%, and the purity of magnesium ingot is above 99.95% (need to meet the requirements of GB / T 13748.9-2005 standard).

[0023] Put the reactor 1 into the resistance furnace 2 with a crane, start to heat up, start to add titanium tetrachloride after 5 hours at 800°C constant temperature, the purity of the added titanium tetrachloride is more than 99.9% (need to meet the re...

Embodiment 2

[0025] Taking a new reactor with a diameter of φ1800mm and a height of 3400mm as an example, the effective space volume is 6.75m 3 Take the new reactor as an example. After soaking the inner wall of the newly made reactor with 10% dilute hydrochloric acid for 10 days, rinse the inner surface with clean water to reveal the metallic luster, and quickly dry the surface with compressed air. Add 4.72m to the reactor 3 (weight is 7.9 tons) magnesium chloride and 500kg magnesium ingot, assembles reactor. Start the vacuum pump to degas the reactor for 2 hours and then fill it with argon for protection. Among them, the purity of magnesium chloride is above 99%, and the purity of magnesium ingot is above 99.95% (need to meet the requirements of GB / T 13748.9-2005 standard).

[0026] Use a crane to load the reactor into the resistance furnace, start to heat up, and start adding titanium tetrachloride after a constant temperature of 800°C for 5 hours (need to meet the requirements of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com