Environmentally friendly super-concentrated bath tablets and particles and preparation method thereof

A production method, ultra-concentration technology, applied in chemical instruments and methods, detergent powder/flakes/sheets, ampholytes/electrically neutral surface active compounds, etc., can solve the problem of inaccurate usage, high packaging and transportation costs, Detergent is not easy to carry and other problems, to achieve the effect of enhancing the stimulating effect and improving the decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

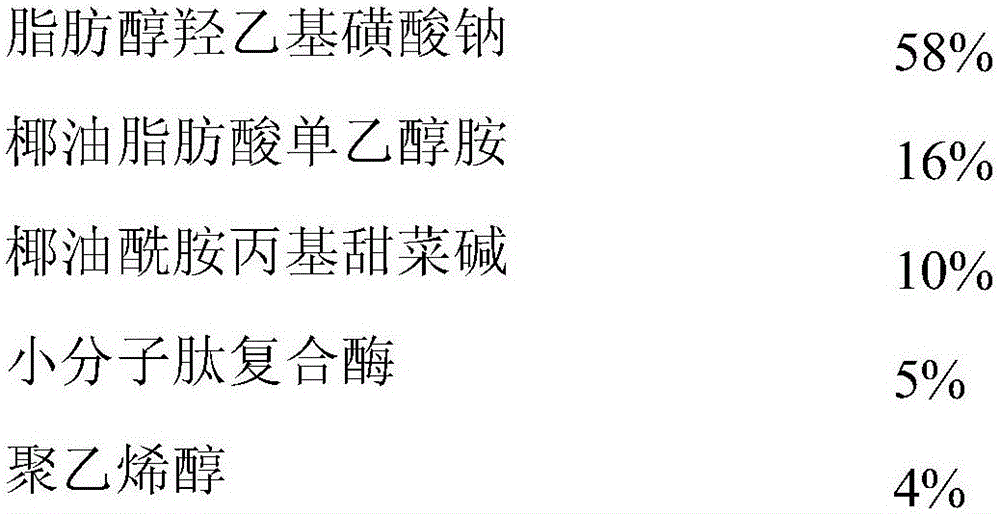

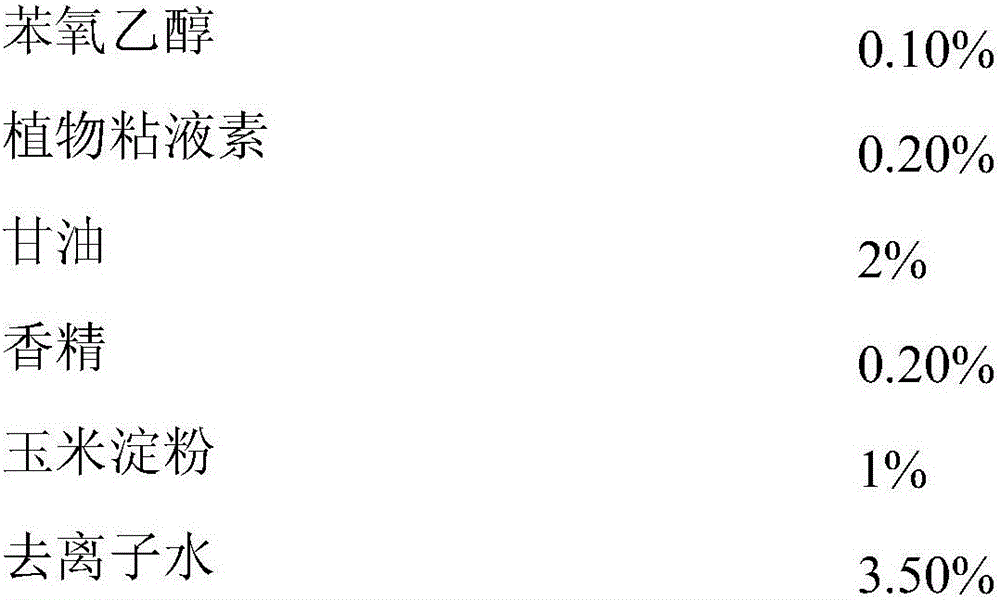

[0031] An environmentally-friendly super-concentrated bathing tablet / particle, which is prepared by the following method;

[0032] Step S001. Take 58 grams of anionic active agent fatty alcohol sodium isethionate, 16 grams of nonionic active agent coconut fatty acid monoethanolamine, and 10 grams of amphoteric surfactant cocamidopropyl betaine, put them in a preparation container and Keep stirring

[0033] Then take 4 grams of thickener polyvinyl alcohol, 0.1 grams of preservative phenoxyethanol, 1 gram of filler corn starch, 2 grams of glycerin, 0.2 grams of plant mucin aloe extract, 0.2 grams of flavor, and an appropriate amount of deionized water. Put it into the preparation container, continuously stir evenly and fully mix the components to obtain a liquid environmentally friendly super-concentrated bath tablet / particle production raw material;

[0034] Step S002: Put the liquid environmentally friendly super concentrated bath sheet / granule manufacturing raw materials prepared i...

Embodiment 2

[0044] An environmentally-friendly super-concentrated bathing tablet / particle, which is produced by the following method;

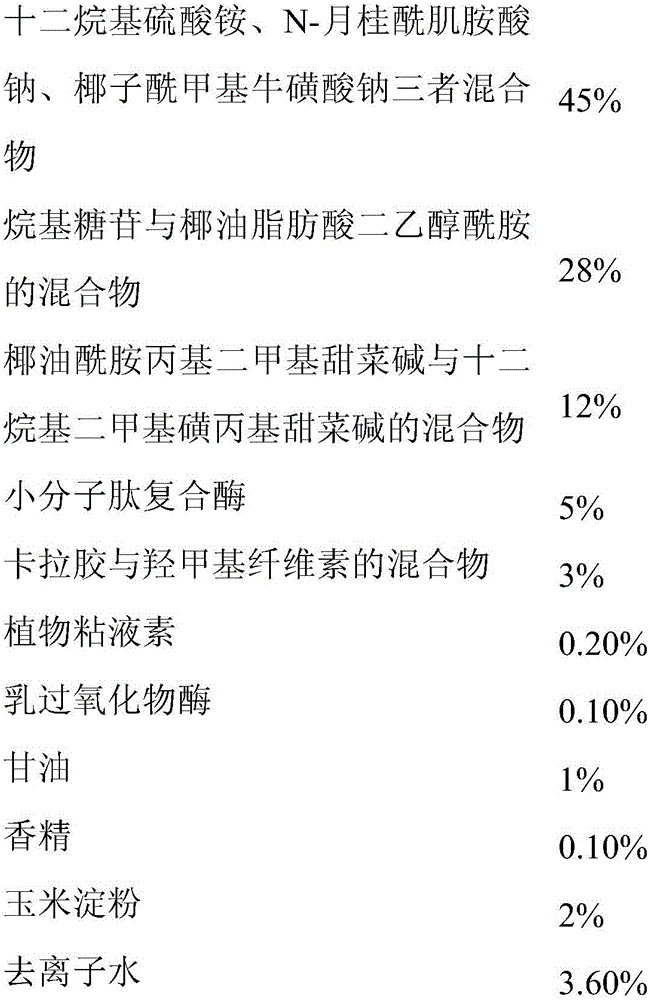

[0045] Step S001. Combine 25 grams of ammonium lauryl sulfate, 10 grams of sodium N-lauroyl sarcosinate, and 15 grams of sodium cocoyl methyl taurate as an anionic active agent, so that the total mass is 45 grams and the mixing ratio is 5. :2:3 mixed anionic active agent;

[0046] Mix 12 grams of nonionic active agent alkyl glycosides with 16 grams of coconut fatty acid diethanolamide to form a mixed nonionic active agent with a total mass of 28 grams and a mixing ratio of 3:4;

[0047] Mix 9 grams of amphoteric surfactant cocamidopropyl dimethyl betaine with 3 grams of dodecyl dimethyl sulfopropyl betaine to form a mixture with a total mass of 12 grams and a mixing ratio of 3:1 Mixed type amphoteric surfactant;

[0048] Put the above-mentioned mixed anionic active agent, non-ionic active agent, and amphoteric surfactant into the preparation container and stir c...

Embodiment 3

[0061] An environmentally-friendly super-concentrated bathing tablet / particle, which is produced by the following method;

[0062] Step S001. Mix 25 grams of the anionic active agent lauryl phosphate potassium salt, 20 grams of dodecyl phosphate triethanolamine, and 15 grams of disodium lauryl polyoxyethylene ether sulfosuccinate, thereby A mixed anionic active agent with a total mass of 60 grams and a mixing ratio of 5:4:3;

[0063] 15 grams of non-ionic active agent PEG-7 olive oil glyceride;

[0064] Put the above-mentioned mixed anionic active agent and non-ionic active agent into the preparation container and keep stirring, and then take 10 grams of amphoteric surfactant decyl dimethyl hydroxypropyl sultaine, thickener xanthine 3 grams of glue, 0.1 grams of preservative lactoperoxidase, 2 grams of glycerin, 0.2 grams of plant mucin aloe extract, 0.2 grams of aromatic flavor, 2 grams of filler corn starch, and a suitable amount of deionized water. In the preparation container, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com