Bio-fertilizer for efficient degradation of atrazine and preparation method thereof

A technology of atrazine and bio-fertilizer, applied in the field of bio-fertilizer, can solve problems such as inability to grow, loss of degradable atrazine activity, unstable degradation performance, etc., to increase organic matter content, improve field adaptability, and improve degradation The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

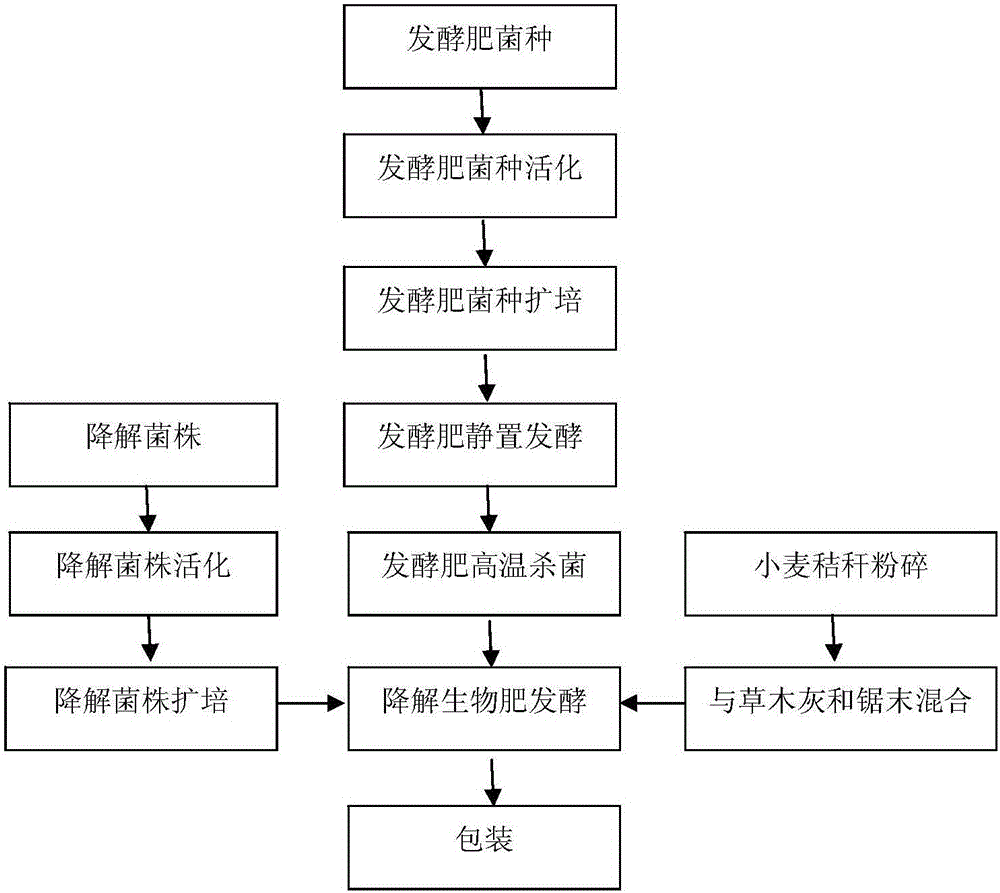

Method used

Image

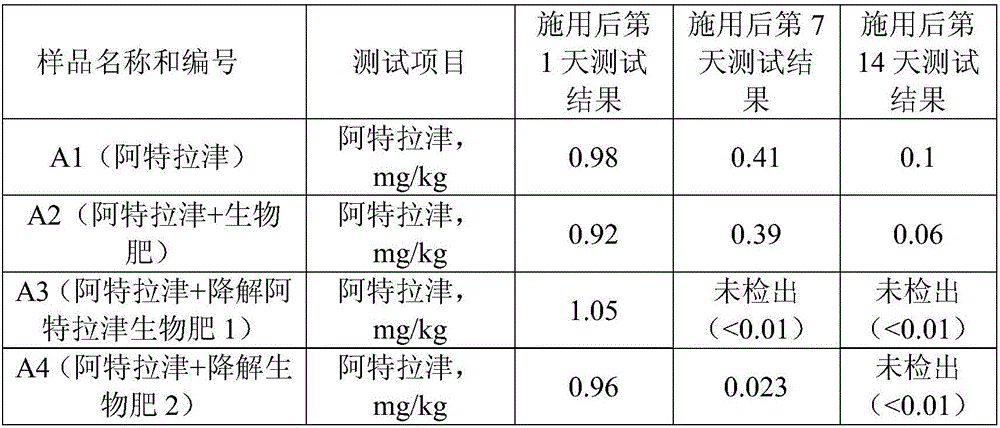

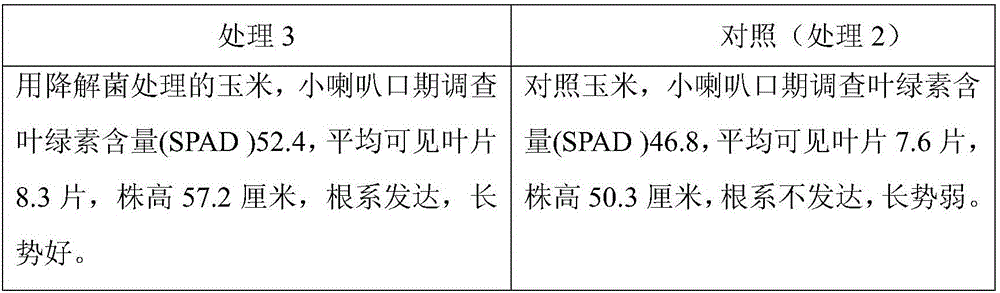

Examples

Embodiment 1

[0028] Embodiment 1: Preparation of fermented bacterial fertilizer

[0029] 1. Activation of Bacillus subtilis and Bacillus licheniformis

[0030] Add the freeze-dried powder of Bacillus subtilis (the number of viable bacteria ≥ 100 billion / g) into the sterilized LB liquid medium at an amount of 1%, and place it in a shaker at 30°C with a rotation speed of 180 rpm Activation culture for 12 hours per minute; the activation of Bacillus licheniformis is the same as that of Bacillus subtilis;

[0031] LB liquid medium: peptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, pH 7.0;

[0032] 2. Activation of Lactobacillus plantarum and Lactobacillus rhamnosus

[0033] Add the freeze-dried powder of Lactobacillus plantarum (the number of viable bacteria ≥ 100 billion / g) into the sterilized MRS liquid medium at an amount of 1%, and culture it statically at 37°C for 12 hours, and the measured OD value is 0.5; then transfer once again, when the OD value reaches 0.5 again; press 10...

Embodiment 2

[0040] Embodiment 2 prepares biological fertilizer

[0041]1. Activation of fermentation strains

[0042] Two bacterial strains, BTAH1 (preservation number: CGMCC No.1113) and Graninella strain HBZA0511 (preservation number: CGMCC No.1801), are used;

[0043] Add the strain BTAH1 of the genus Exiguobacterium into the activation medium (1 / 10 of the LB medium), rotate at 120 rpm at 30°C, and cultivate on a shaker for 24 hours. After the OD value reaches 0.5, obtain the seed liquid and set aside; The activation of Graninella strain HBZA0511 is the same as that of Exiguobacterium strain BTAH1;

[0044] 1 / 10 LB medium: every 1000ml contains 0.5g yeast extract, 1g peptone and 1g sodium chloride.

[0045] 2. Strain fermentation: the seed liquid is transferred to the fermenter according to the inoculum amount of 10% by mass ratio (the seed liquid of the two kinds of bacteria is respectively pressed by 5% consumption); the fermentation temperature is 30 ° C, and the stirring speed is...

Embodiment 3

[0059] Embodiment 3: Preparation of fermented bacterial fertilizer

[0060] 1. Activation of Bacillus subtilis and Bacillus licheniformis

[0061] With embodiment 1.

[0062] 2. Activation of Lactobacillus plantarum and Lactobacillus rhamnosus

[0063] With embodiment 1.

[0064] 3. Fermentation material preparation

[0065] Take the corn plants and break off the corn, harvest the corn, dry it and crush it with a grinder, the crushing fineness is between 2mm-3mm, and obtain corn stalks; the cottonseed cake, wheat bran, corn stalks, and fish bone meal are separated according to the quality Mix at a ratio of 9:9:48:1, sterilize evenly at 80°C for 20 minutes, dry in the sun, and use it as a fermentation material for later use;

[0066] 4. Fermentation

[0067] Add the expanded fermentation liquid of Lactobacillus plantarum and Lactobacillus rhamnosus to the fermented materials after sterilization and drying according to the inoculation amount of 2.8%, and then add the activa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com