A chiral metal nanostructure for realizing circular dichroism and its preparation method

A metal nanostructure and circular dichroism technology, which is applied in nanostructure manufacturing, specific nanostructure formation, nanotechnology for materials and surface science, etc., can solve the problem of small sample area, high cost, chiral metal nanostructure The method is cumbersome and complicated, and achieves the effect of simple operation and reduced preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1. Prepare 1cm*1cm glass slides a and b, and then prepare several 1cm*2cm glass slides, clean them and do hydrophilic treatment. The specific process is: scrub the glass slides with detergent, and use Ultrasonic acetone for 15 minutes, rinse the acetone on the glass slide with deionized water for 3-5 minutes, then sonicate the alcohol on the glass slide for 15 minutes, rinse the alcohol on the glass slide with deionized water for 3-5 minutes, put in concentrated sulfuric acid and concentrated hydrogen peroxide at a volume ratio of Soak in the 3:1 mixture for 16 hours, rinse with deionized water for 5 minutes after soaking, and then dry it with nitrogen and put it in a nitrogen cabinet for storage;

[0037] Step 2. Put the two glass slides a and b cleaned in step 1 into the center of the petri dish, with b on the top and a at the bottom; c glass slides into the petri dish, leaving a certain gap with a and b; Pour deionized water into the petri dish, the liquid level of...

Embodiment 2

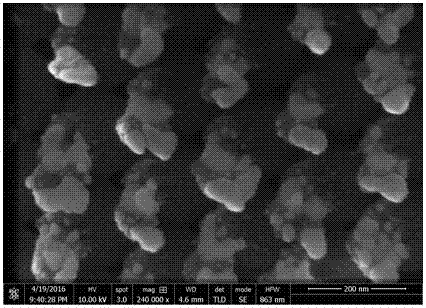

[0048] The preparation steps are basically the same as in Example 1. The only difference is that the coating method in step 9 is that after a group of silicon dioxide and silver film materials are vapor-deposited in Example 1, the angle does not change, and a group is vapor-deposited again to obtain image 3 Chiral metal nanostructure shown.

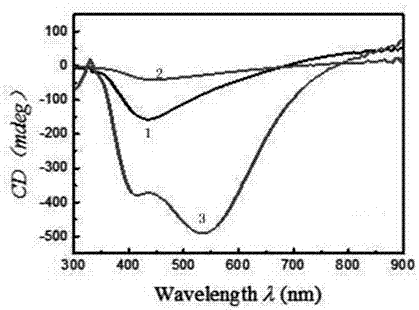

[0049] The circular dichroism of the prepared structure is measured by normal incidence or oblique incidence of light. Such as figure 1 As shown in curve 3.

Embodiment 3

[0051] The preparation steps are basically the same as in Example 1. The only difference is that the counterclockwise coating process in step 9 is: vapor-deposit A50nm on the polystyrene bead template substrate, and then rotate 45° counterclockwise to vapor-deposit B50nm so that part of B is placed on A stepped shape is formed on A; the substrate of B is vapor-deposited, and then rotated 45° counterclockwise, and A50nm is vaporized, so that part of A is placed on B to form a step shape, which is rotated and vaporized sequentially, and finally an alternating AB is formed Spiral structure.

[0052] The circular dichroism of the prepared structure is measured by normal incidence or oblique incidence of light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com