Machining method of conical round steel pipe

A processing method and a technology of round steel pipes, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of delaying the project cycle, prolonging the production cycle, and increasing construction costs by the scheduled time, so as to reduce the project cost and shorten the project cycle , The processing method is simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The processing method of the conical circular steel pipe of the present invention includes a processing platform, and the processing method of the conical circular steel pipe of the present invention is completed by the following steps:

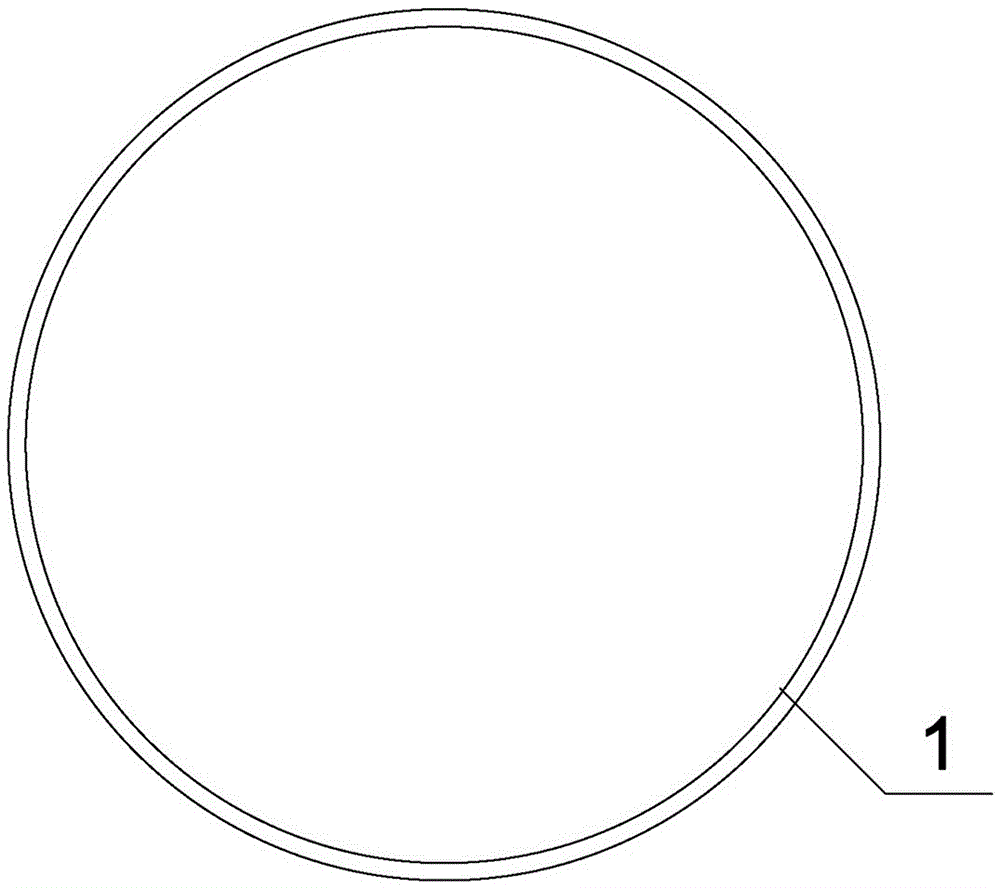

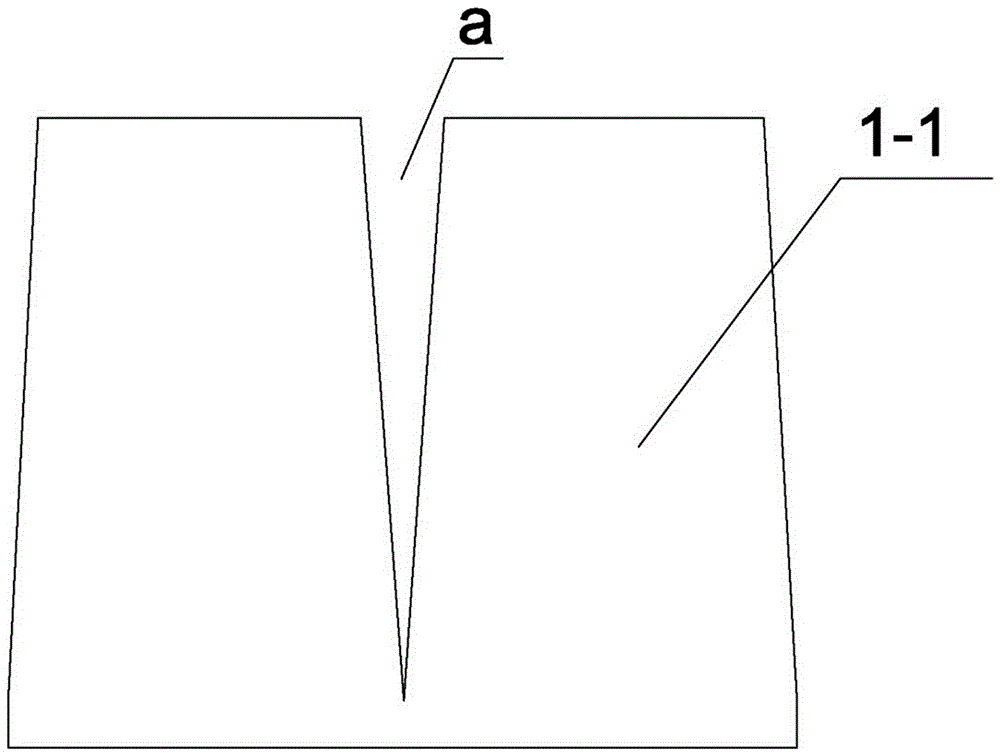

[0028] Step 1. Preparations for the production of the tapered round steel pipe 1-2: ①According to the engineering drawing, intercept the basic round steel pipe 1 that conforms to the large diameter and length of the tapered round steel pipe (see figure 1 , figure 2 ); ② According to the design, make a number of wedges 2 of each size in three sizes, large, medium and small (see Figure 5 , Image 6 ); ③ intercept an outer casing 3 with a diameter larger than the basic round steel pipe 1 by 20 to 30 mm and the length is basically equal to the basic round steel pipe (see Figure 5 , Image 6 ); ④ Grind the surface of the processing platform until it is flat; ⑤ Draw a circle center shared by the basic round steel pipe 1 and the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com