A device and method for correcting the middle groove of a scraper machine

A technology of a correction device and a scraper machine, which is applied in the field of scraper machine maintenance devices, can solve the problems of unevenness in the middle groove, poor correction safety, and low correction efficiency, and achieve good flatness, high safety, and high correction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

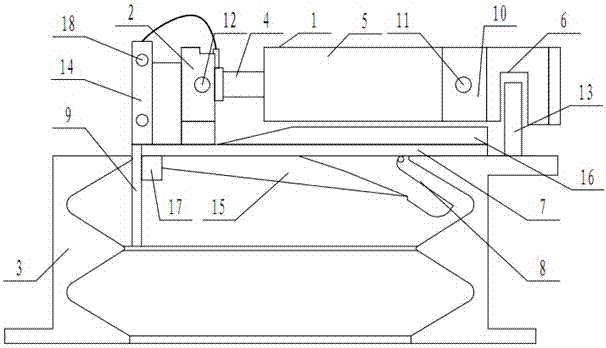

[0028] Embodiment 1: as Figure 1-2 As shown, a device for correcting the middle groove of a scraper machine includes a two-way hydraulic cylinder 1, the end of the cylinder rod 4 of the hydraulic cylinder 1 is connected to the support 2 through a rotating pin 12, and the support 2 is movably placed in the middle groove 3 and limit it left and right. The tail end of the cylinder barrel 5 of the hydraulic cylinder 1 is connected with an inverted U-shaped card slot 6, and the U-shaped card slot 6 is engaged with the pin row pin fixing plate 13 on the upper right side of the middle slot 3. superior.

[0029] The above-mentioned support 2 is provided with a support plate 7 of the cylinder 5, and its lower left side is provided with an abutment plate 9, and the right end of the support plate 7 is placed on the upper end surface of the middle groove 3, and a U-shaped groove 8 inclined downward to the right is arranged under it. , the abutment plate 9 abuts against the left side wal...

Embodiment 2

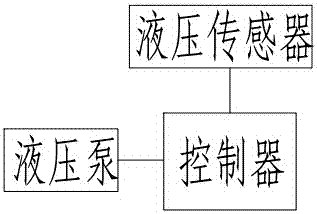

[0036] Embodiment 2: A method for correcting a device for correcting a slot in the middle of a scraper machine, the method comprising the following steps:

[0037] (1) Install the support in the middle groove, and snap the U-shaped slot of the hydraulic cylinder to the part to be bent on the middle groove pin row pin fixing plate;

[0038] (2) Connect the oil inlet pipe of the hydraulic cylinder to the hydraulic pump;

[0039] (3) Set the oil pressure threshold 10MPa and pressure change rate of the oil inlet pipeline through the controller;

[0040] (4) When the oil pressure reaches 80% of the pressure threshold from 0, the pressure change rate is controlled at 0.5MPa, and between 80% and 100%, the pressure change rate is controlled at 0.25MPa;

[0041] (5) When the pressure threshold in step (4) reaches the maximum, the time lasts for 3-5 minutes, and the oil return of the hydraulic cylinder is loosened, and step (4) is repeated 3-5 times;

[0042] (6) Repeat steps (1)-(5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com